As competition in the market intensifies, the price of laser cutting machines has also shown a gradually decreasing trend, which has further promoted the popularity and application of laser cutting machines. The price of a 3000W fiber laser cutting machine is affected by many factors, such as brand, configuration, specific format, etc. According to market demand analysis:

The price of a 3000W laser cutting machine is roughly between 120,000 and 300,000. The specific price depends on the brand configuration, and the prices are different for different cutting materials. The price of 3000W laser cutting machine is divided into many types of cutting machines, such as pipes and metals.

If you choose a branded laser cutting machine, the price is roughly around 300,000 to 450,000, while the price of a second-tier brand cutting machine may be around 350,000. If it is customized, the price cannot be fixed.

You also need to consider the following factors when purchasing a laser cutting machine:

- Configuration: including the configuration of core components such as laser cutting heads, lasers, motors, machine tools, CNC systems, and laser lenses. In particular, the quality and quality of the laser largely determines the basic price of the laser cutting machine.

- Software system: A good laser company will have a professional technical department to develop, upgrade and update related software systems. A better software system means a higher price, but it can be better compatible with the hardware, perfect Match and maximize functionality.

- Accessories and consumables: These are also factors that affect the price of laser cutting machines.

Advantages of KRRASS 3000W Fiber Laser Cutting Machine

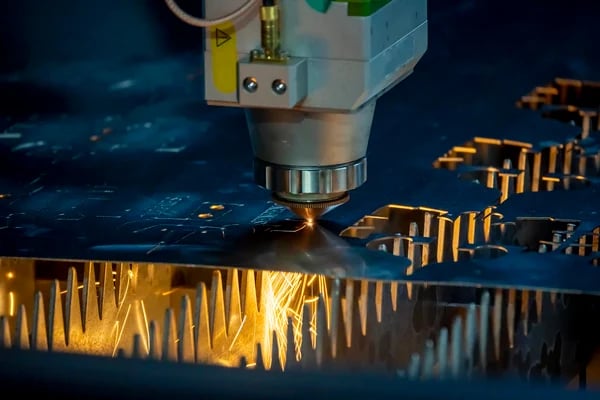

- High Cutting Power:With a 3000W fiber laser source, the machine delivers powerful cutting capabilities, allowing it to cut through a wide range of materials with ease. This high cutting power enables efficient processing of various metals, including steel, stainless steel, aluminum, copper, and brass.

- Precision and Accuracy:The KRRASS 3000W fiber laser cutting machine provides exceptional precision and accuracy in cutting, ensuring that even the most intricate designs and complex geometries are executed with high-quality results. This level of precision is crucial for industries that require tight tolerances and fine details in their finished products.

- High Speed Cutting:Equipped with advanced laser technology and high-speed motion systems, the machine offers rapid cutting speeds, leading to increased productivity and throughput. This allows manufacturers to complete projects faster and meet tight production deadlines efficiently.

- Versatility in Material Compatibility:The KRRASS 3000W fiber laser cutting machine is compatible with a wide range of materials, including metals, alloys, and non-metallic materials such as plastics and composites. This versatility makes it suitable for diverse applications across various industries, from automotive and aerospace to electronics and signage.

- Minimal Maintenance Requirements:Thanks to its robust design and high-quality components, the KRRASS 3000W fiber laser cutting machine requires minimal maintenance, resulting in reduced downtime and lower operating costs over its lifespan. This makes it a cost-effective solution for manufacturers seeking reliable and efficient cutting equipment.

- User-Friendly Operation:The machine is designed with user-friendly features and intuitive controls, making it easy to operate for both experienced operators and newcomers to laser cutting technology. The touchscreen interface and integrated software allow operators to program cutting parameters, import designs, and monitor the cutting process with ease.

- Safety Features:Safety is prioritized in the design of the KRRASS 3000W fiber laser cutting machine, with built-in safety features such as safety enclosures, interlocks, and emergency stop buttons to ensure operator protection and compliance with safety regulations.

- High-Quality Finished Products:With its precise cutting capabilities and superior cut quality, the KRRASS 3000W fiber laser cutting machine produces high-quality finished products with clean edges, smooth surfaces, and minimal heat-affected zones. This enhances the overall quality and aesthetics of manufactured parts and components.

Concusion

It is recommended that when choosing, first determine your own needs, learn about the machine performance and basic parameters in the market or consult with peers who have purchased laser cutting machines, and choose several manufacturers with strength and favorable prices for communication and proofing. KRRASS sheet metal cutting machine offers a combination of power, precision, versatility, and reliability, making it an ideal choice for manufacturers looking to optimize their cutting processes and achieve superior results in their operations.