Overview

The 3.2m Press Brake stands out as a highly sought-after model, renowned for its exceptional machining capabilities and extensive applications. Its popularity stems from its proficiency in handling a diverse array of intricate metalworking tasks, catering to both sizable components and delicate parts. Boasting a generous table size, it proves adept at managing even larger workpieces, resulting in enhanced productivity.

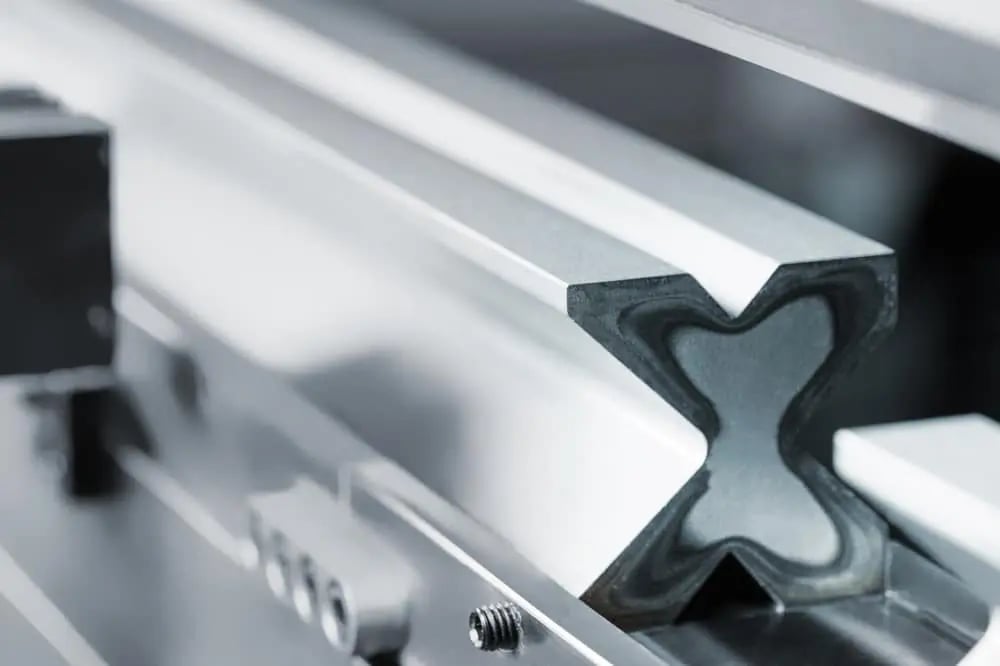

Adding to its allure, the 3200 press brake features a comprehensive range of capabilities and adaptable configurations. This machine can be outfitted with an array of tools and dies, facilitating various machining methods such as bending, drawing, and punching. This versatility allows it to seamlessly meet the distinctive requirements of different industries.

In critical sectors like aerospace, construction, and electronics, the 3200 Press Brake plays a pivotal role, offering robust support for the advancement of the metal processing industry. Its prowess in addressing complex metalworking tasks contributes significantly to the evolution and growth of various fields, underscoring its significance as a cornerstone in modern manufacturing.

Importance of 3.2m Press Brakes In The Metalworking Industry

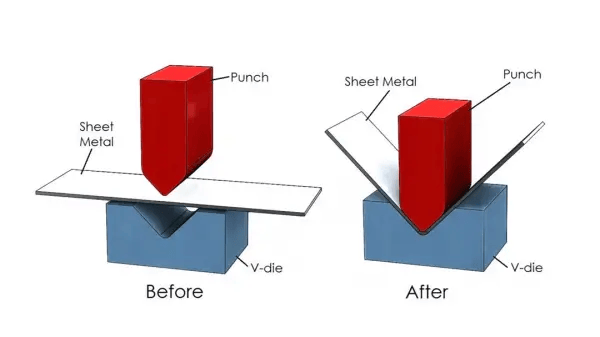

The 3200 press brake is a sheet metal bending machine with a maximum bending length of 3200 and is suitable for medium-sized metalworking tasks and can handle many common workpiece sizes. It can cope with complex metalworking tasks, whether for large parts or fine components. Its powerful machining capabilities make it useful in areas as diverse as bridges, ships, engines, jewelry, watches, etc. Precise control systems and high-precision machining processes are also essential to ensure dimensional accuracy and machining quality for high-quality metal machining.

At the same time, the 3200 press brake offers a wide range of functions and flexible configurations that can be adapted and optimized for different processing requirements. For example, according to different production bending needs, it is highly flexible and can be equipped with a variety of tools and molds to achieve a variety of processing methods, such as bending, stretching, punching and so on. In addition, some models are equipped with automatic feeding and loading/unloading functions, which further improve production efficiency.

Why Choose 3.2m Press Brake

High-Precision Stamping Capability

In the contemporary landscape of manufacturing, the stamping process is integral, and the measure of high-precision stamping capability serves as a critical indicator of equipment performance. The 3200 press brake, recognized for its excellence, plays a pivotal role in the manufacturing industry due to its remarkable high-precision stamping capability. This capability, attaining millimeter-accurate stamping results, is imperative for the production of top-tier, high-quality products.

The 3200 press brake excels in providing exceptional machining accuracy for stamping a diverse range of complex parts. Whether dealing with substantial workpieces or intricate components, its high-precision stamping capability guarantees accurate detailing in every step of the process. This ensures that operators can confidently manufacture parts and products with dimensional accuracy and consistent quality.

Large Format Stamping Capability

Large format stamping technology assumes a crucial role in contemporary manufacturing, particularly in industries such as automotive and aerospace. These sectors necessitate large-format stamping capabilities to manufacture substantial parts, offering advantages in material savings and lower production costs. The 3200 press brake stands out as a powerful large-format stamping machine, contributing significantly to these industries.

This press technology extends its applications beyond automotive and aerospace, finding relevance in sectors like construction, home appliances, and electronics. To meet the diverse needs of these industries, large-size stamping presses require technical sophistication and intricate structural designs. The 3200 press brake stands as a testament to precise design and manufacturing, providing a robust stamping capability to handle a wide spectrum of large-size parts stamping tasks.

Efficient and Stable Press Performance

Efficiency and stability in press performance are vital considerations in modern manufacturing. This entails maintaining accuracy and stability at high speeds, resulting in high-quality press results. Furthermore, efficient and stable stamping performance necessitates robust troubleshooting and automatic protection functions. These features ensure that the equipment halts promptly upon encountering a problem, preventing potential significant losses.

Humanized Operation Interface

Efficiency and stability are essential for high-speed press operations. The 3200 Press Brake maintains accuracy and stability at elevated speeds, ensuring high-quality results. Automatic protection functions add to its reliability, stopping the equipment promptly in case of issues and preventing potential losses.

Humanized Operation Interface

With technological advancements, the operation interface of stamping equipment is evolving towards increased humanization. A user-friendly, humanized operation interface enables users to familiarize themselves with the operational processes swiftly, reducing the learning curve. This interface incorporates rich information display and data analysis functions, empowering operators to comprehend real-time equipment operation status and make prompt adjustments to production strategies. Additionally, a humanized operator interface should encompass robust protective measures to ensure operator safety.

In conclusion, the essential features of modern stamping equipment encompass high precision, large size, high efficiency and stability, and a humanized operation interface. Equipment embodying these characteristics not only meets the demand for high-quality and high-efficiency production but also enhances the competitiveness of enterprises. In the broader context, it contributes to the transformation and upgrade of China's manufacturing industry. When selecting press equipment, enterprises should meticulously consider these characteristics to ensure the acquisition of high-quality equipment aligns with their specific needs.

Four Advantages of 3.2m Press Brake

Improved Processing Capability

The 3200 press brake, equipped with outstanding processing capabilities and high precision, emerges as a powerhouse for swiftly and accurately completing a myriad of intricate stamping tasks. Its remarkable high-speed stamping capability and rapid response time to movements significantly elevate productivity. Operators, leveraging these features, can efficiently accomplish a greater number of processing tasks in less time, thereby expediting production cycles and curbing manufacturing costs.

Versatility in Application

The machine's versatility and adaptable configurations make it a dynamic solution for a diverse array of machining needs. Whether handling substantial components or intricate details, the 3200 press brake proves to be adept. Additionally, its ability to be equipped with various tools and molds for different processing methods, such as bending, stretching, punching, further extends its application scope across various industries

Reduction in Labor Intensity

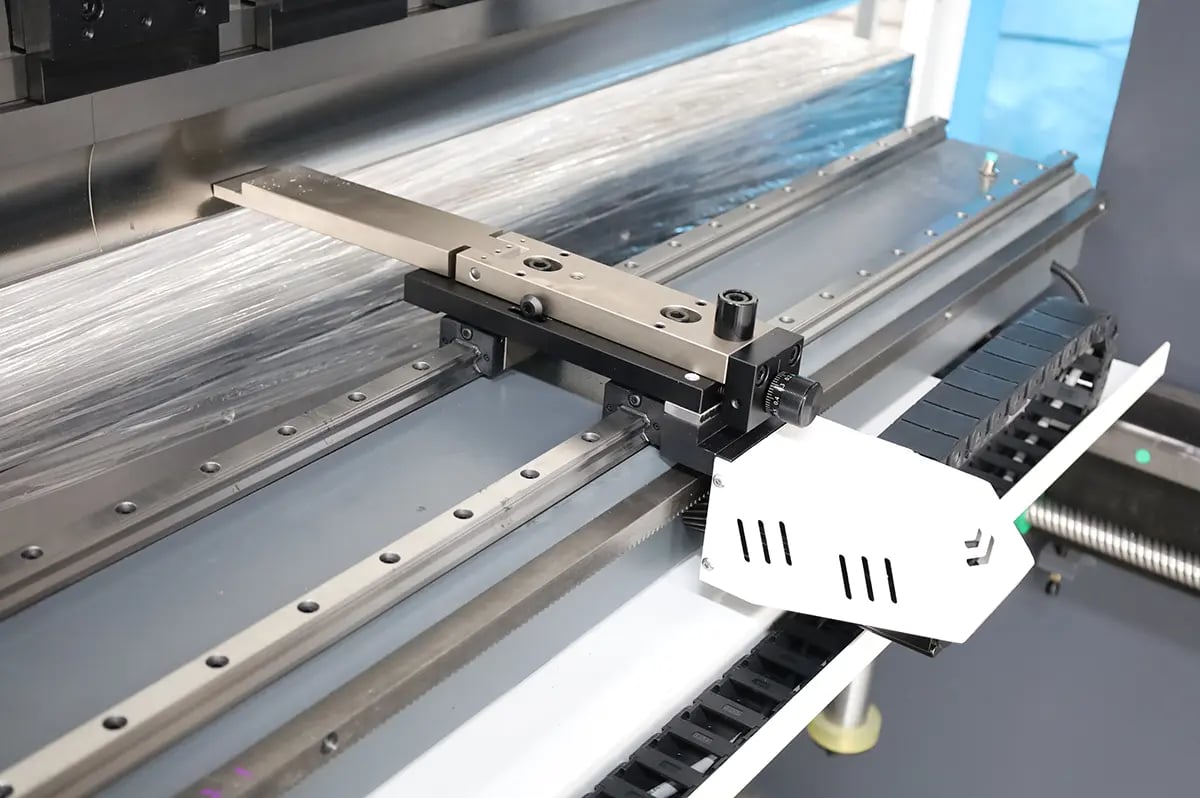

The 3200 press brake takes a stride towards operational efficiency by alleviating the labor intensity for operators. The incorporation of automated functions, coupled with a user-friendly operation interface, streamlines operations. Automated loading and unloading functions, along with an intelligent CNC system, simplify tasks for operators. By allowing operators to set parameters with ease, the equipment autonomously performs the majority of the work, thereby diminishing physical labor and enhancing overall operational efficiency.

Reliability and Durability

Crafted with precision and constructed from high-quality materials, the 3200 press brake prioritizes reliability and durability. Its stable operation and prolonged service life contribute to a more dependable production process. This, in turn, instills confidence in operators, minimizing equipment failures and downtime. The result is an elevated level of stability and sustainability in the production line, ultimately bolstering the overall efficiency of manufacturing operations.

Application Scenarios

Automotive Parts Processing

In the realm of automotive parts stamping, the 3200 Press Brake assumes a pivotal role as a crucial stamping equipment. It excels in shaping various metal sheets into precise forms and dimensions through robust pressure application and meticulous mold control. Widely integrated into automotive manufacturing, it proves indispensable for crafting components like cover parts and structural elements.

The 3200 Press Brake distinguishes itself with its formidable press force and unwavering rigidity, ensuring an unparalleled level of control over metal sheets during processing. This precision is further augmented by an advanced mold and fixture system that facilitates swift adjustments tailored to the distinct processing requirements of various automotive components. This not only enhances overall production efficiency but also fosters a heightened level of flexibility in response to dynamic manufacturing needs.

Leveraging cutting-edge CNC technology, the 3200 Press Brake achieves an unparalleled level of high-precision press processing. Precisely managing the closing height and pressure of the mold, it guarantees that the processed parts align flawlessly with design specifications. This precision minimizes the need for extensive corrections and adjustments in later stages, streamlining the manufacturing process and bolstering efficiency.

Safety takes center stage in the design of the 3200 Bending Machine. Equipped with an automatic detection system, it promptly identifies abnormalities in molds and fixtures, triggering protective measures to prevent equipment damage and mitigate the risk of accidents that could jeopardize personnel. Complemented by an array of safety features, including a photoelectric protection device and an emergency stop button, the machine prioritizes the well-being of operators, fostering a secure working environment.

In essence, the 3200 Press Brake not only contributes significantly to the production of automotive components but also redefines industry standards by combining precision, adaptability, and safety. As an essential player in the intricate dance of automotive manufacturing, it remains a symbol of innovation, efficiency, and a steadfast commitment to the well-being of those operating within its sphere.

Processing of Body Covering Parts and Structural Parts

Processing of body covering parts and structural parts is one of the crucial links in the automobile manufacturing industry. The 3200 press brake plays a key role in this process. This high-performance machine is capable of handling sheet metal up to and exceeding 3,200 mm in thickness, providing a precise and reliable machining solution for the manufacture of bodywork components.

With the Model 3200 press brake, operators can easily bend and form sheet metal to achieve a wide range of complex shapes. For body cladding parts, this means being able to accurately produce doors, hoods, roofs and other parts that meet design requirements. As for body structural parts, the high pressure and precision of the Model 3200 Bending Machine ensures the strength and stability of parts, such as body frames, support structures and other important components.

Household Appliance Industry

Stamping Of Housings And Accessories

Stamping of housings and accessories is a critical process in the household appliance industry, especially in combination with the 3200 press brake, which allows higher levels of productivity and product quality to be realized. This powerful machine can cope with larger sheet metal sizes and offers a wide range of possibilities for the processing of housings and fittings for household appliances.

Improve Product Appearance And Performance

Paired with the 3200 bending machine, intricate and elaborate shapes come to life. Numerous household appliances demand distinctive designs, featuring curves, corners, and other specialized forms. The significance of the bending machine's high-pressure capacity and meticulous control becomes particularly evident in this context. Operators gain the ability to finely tune the machine's parameters in alignment with product design specifications. This precision allows the bending of metal sheets into a myriad of complex shapes, facilitating the diversification and personalization of product appearances with utmost accuracy.

Bending And Molding Of Sheet Metal

Within the construction industry, the shaping and molding of sheet metal emerge as integral processes. Utilizing specialized machinery like the 3200 press brake, precision is achieved in bending and forming metal sheets of varying thicknesses and compositions. These techniques find extensive application in crafting essential building components, including diverse beams and columns, along with ornamental exterior panels.

Processing of building structures and decorative materials

Within the construction sector, sheet metal serves as a versatile material for producing an array of structural and decorative elements. Machines like the 3200 press brake facilitate the precision cutting of sheet metal, tailoring it to the specific size and shape requirements for applications such as wall cladding, roofing, railings, stair handrails, and beyond. Achieving the desired design and maintaining a high-quality appearance necessitates meticulous machining of these metal products.

Overall, in various industries, including construction, the bending and shaping of sheet metal are pivotal processes. Advanced equipment like the 3200 press brake significantly enhances the accuracy and efficiency of sheet metal processing, catering to the diverse requirements across different sectors.