The panel bender is a machine with functions similar to the press brake but is more automatic and has more features.

In the past, manual bending machines were used for metal bending.

With the continuous progress of technology, sheet metal forming has entered the era of automation.

Sheet metal bending can be divided into manual bending, semi-automatic bending, and full-automatic bending centers.

Automatic tool changing systems, measuring systems, etc., improve the efficiency of metal bending.

Then came the panel bender, which has functions similar to those of the traditional press brake.

The blade of the panel bender can form a flange in the horizontal direction, and the blank holder in the other direction can keep the material stable.

Standard bending blades can produce many types of radii. The bending of the panel bender will not leave marks.

Compared with the bending workpiece of the press brake, it will be more aesthetic and clean.

Compared with the previous press brake, the panel bender has the advantages of being labor-saving and high-speed.

The panel bender can perform fully automatic bending processes, including automatic loading and unloading of tools, feeding, measuring, bending, and outputting.

It has a short bending stroke, and fast feeding speed, and produces highly accurate workpieces.

Special tools can be used for complex bendings, such as crimping and offset bending.

However, not all workpieces are suitable for the panel bender.

Generally, it is better for producing box-type workpieces as it can bend the side of the whole box at once.

Nowadays, a panel bender or press brake connected to a robot can achieve full automation, but their functions are not as complete as those of a robot bending center.

Understanding the differences between the panel bender and the traditional press brake can help you choose the right machine.

How Does A Panel Bender Work?

The working principle of the panel bender is different from that of the press brake.

When operating the panel bender, the operator only needs to load the sheet metal.

The workpiece positioning, bending, and reversing are controlled by the machine and software.

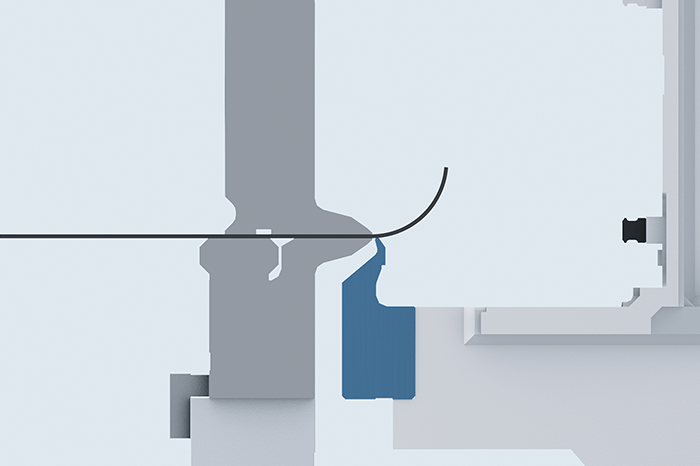

The panel bender does not press the metal plate into the lower die through punches.

The panel bender is to fix the plate through a pair of blades and bend it up and down to form the final profile.

When bending a complex angle, the blade oscillates around a single bending point until the desired angle is reached.

It does not move up and down along a straight line, which is different from the press brake.

After positioning the plate, the panel bending machine can quickly adjust to the correct tool length.

When bending, after the workpiece is positioned, the clamping beam tool clamps the workpiece in place.

The lower tool moves upward to bend in a positive direction; The top tool moves down to bend in the negative direction.

The upper pressing tool and the bottom pressing tool clamp the sheet metal in place.

But they will not directly bend the metal, but the upper and lower blades apply pressure to form it.

The metal plate of the panel bending machine is placed under the clamping claw, and then the clamping claw descends and clamps the workpiece.

The longer the plate protrudes from the other side, the higher the flange produced by the throat of the machine.

The panel bending machine is very fast and accurate. After the workpiece is positioned, the bending tools move up and down to form a flange.

In the process of side bending, the clamping claw rotates the workpiece, and the tools move up and down to bend the plate.

The movement of the tools determines the bending angle and radius of the workpiece, so even curling can be formed.

The bending blade forms more than 90 degrees of material, and the tool drops to form the final curling.

Box type, flat workpieces, and large workpieces are also suitable for panel bending machine.

What Are the Features of the Panel Bender?

Advantages

The panel bending machine has an automatic tool changer, which reduces the installation time.

The bending of all workpieces can be completed through a complete set of tools.

The interactive area of the tools of the panel bender on the surface of the metal plate is very small.

There are few scratches on the surface of the workpiece produced in this way.

The tool wear of the panel bender is also very small because the friction between the tool and the metal surface is small.

The whole process of the panel bender can be carried out automatically, which saves human resources.

The bending angle change of the panel bender is formed by the movement of the upper and lower blades.

So its tools are not as complicated as press brakes.

The panel bending machine has an automatic tool changer, which can quickly change tools to adjust the bending angle.

Some large workpieces with positive and negative flanges are suitable for manufacturing with panel bending machine .

If the panel bending machine can automatically set the blank holder, only one operator can handle it.

The panel bender only applies pressure to the metal plate through the upper and lower blades.

This bending method makes the change and springback of the metal plate in the bending process less obvious.

So it can bend the whole side of the box at one time.

The bending method of the panel bender is very suitable for the production of boxes, covers, and similar items.

There are some safety problems when using a press brake to make small parts.

While the panel bending machine can produce smaller profiles by clamping claws or manually manipulating.

Disadvantages

The panel bending machine also has some disadvantages.

The panel bending machine is more expensive, so it is less popular than the press brake.

The panel bending machine cannot handle thicker plates like the press brake.

Due to the limited throat depth and opening height of the panel bender, it is more suitable for the production of smaller flanges.

The position of the clamping tool and bending blade of the panel bender makes it difficult to produce internal bending on the machine.

Application

Panel bending machine is very suitable for producing square, large, and rectangular workpieces.

These workpieces have high requirements for appearance and shape.

The surface of the workpiece made by the panel bender has few scratches.

Such as refrigerators, air conditioners, and other electrical appliances, as well as doors, elevators, metal furniture and so on.

When selecting a panel bender, it is very important to know which workpieces its bending method is suitable for.

Conclusion

Compared with the press brake, the panel bending machine has more complete functions, higher automation and safer operation.

The cost of the press brake is much less than that of the panel bender, but the operation of the panel machine is simple.

Using the panel bender can also reduce the cost of manpower and material resources through efficient batch production.

ADH produces various CNC press brakes and also various panel benders to meet the different needs of customers.

Our product experts can provide you with suggestions to choose the most appropriate and cost-effective machine.