Introduce

A high-efficiency CNC hydraulic shears, also known as a guillotine shear or power shear, is a machine tool that uses sharp blades to cut sheet metal and other materials. CNC stands for “Computer Numerical Control,” which means the machine is controlled by a computer program.

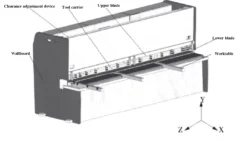

The components of a high-efficiency hydraulic shears usually include the bed, inserts, hold-down fixtures, backgauge, and control systems. The bed is the base of the machine that supports other components. A blade is a sharp edge used to cut material. Hold-down clips hold material in place during cutting. A backgauge is a device that helps control the position of the material as it is cut. Control systems allow machines to be controlled by computer programs.

It works As Follows

Material positioning: first place the metal sheet to be processed on the workbench, and fix it on the workbench with tools such as clamps or magnetic suction.

CNC programming: use the CNC system to write machining programs and import the programs into the control system.

Start the device: Start the trigger, move its knife holder and lower knife edge to the appropriate position.

Cutting process: Under the control of the trigger, the knife holder and the lower knife edge start to cut. During the cutting process, the distance between the knife holder and the lower knife edge will gradually decrease until the metal sheet is cut to the required size.

Completion of processing: Once the processing is completed, the shearing machine will automatically stop and the processed metal sheet will be taken out from the workbench.

In short, the working principle of the high-efficiency hydraulic shears is to use the CNC system to control the shearing action, and quickly and accurately cut the metal sheet into the required size, so as to achieve efficient and accurate metal processing.

Advantages of efficient CNC Hydraulic Shears

There are several advantages to using a CNC shearing machine. One of the main advantages is that it is very accurate, meaning the cuts are consistent and precise. This is important in industries such as automotive, aerospace, and construction. Another advantage is its speed, which means it can cut through large amounts of material quickly. It is also very versatile and can be used to cut a wide range of materials including sheet metal, steel, aluminum, and other metals.

Operated by a computer program designed to control the movement of the machine and the cutting process. The operator enters the desired cutting parameters into the program, such as the size and location of the cut, and the machine does the rest. The operator monitors the machine and makes any necessary adjustments to the program as needed.

China Plate Shearing Machine Suppliers

Proper maintenance is very important to ensure that your CNC shears continue to function properly. This includes cleaning and lubricating the machine regularly, as well as checking blades and other parts for wear. In case of any failure, the operator should have the knowledge to troubleshoot and fix the problem.

In summary, a CNC shear is a powerful and efficient tool for cutting sheet metal and other materials. It is controlled by a computer program, which makes it very accurate and fast. In addition, it has many advantages such as its versatility, accuracy, and speed. Regular maintenance and troubleshooting are necessary to ensure the machine continues to function properly.

How to choose CNC Shearing Machine

When choosing a CNC hydraulic shears, it is important to consider the specific needs of your business and the type of material you will be cutting. Different machines have different capabilities, so you should choose the one that suits your needs. Also, it’s important to consider the size of the machine and the amount of space you have available. Larger machines are usually more powerful, but they also take up more space.

Safety is also an important aspect of CNC shearing machines. Machines should have safety features such as guards to protect the operator and emergency stop buttons. Operators should also be properly trained in the safe use of the machine and should be aware of the potential hazards associated with the machine.

Besides the CNC shearing machine itself, you will need to have the necessary tools, such as blades and punches, in order to perform the cutting. These tools should be the right size and shape for the material you are cutting. They should also be in good condition and should be replaced when worn or damaged.

They are controlled by a computer program, which makes them very accurate and fast. Machines, software, and tools should be carefully selected based on business needs. Regular maintenance and troubleshooting are necessary to ensure the machine continues to function properly. Safety should be a top priority when operating a CNC shearing machine.

Another important aspect to consider when using a CNC shear is the material handling process. Material needs to be loaded into the machine and positioned correctly to begin the cutting process. This process can be done manually by an operator, or it can be automated using a material handling system. Automated material handling systems can greatly increase the efficiency and productivity of CNC shears by reducing manual labor and minimizing errors.

Efficient Hydraulic Guillotine Shear

When maintaining your CNC shears, regular inspections are key to identifying and resolving any issues that may arise. This includes inspecting the machine for any signs of wear or damage and checking that all parts are functioning properly. It is also important to keep an accurate record of the maintenance and repair history of the machine, as this can aid in troubleshooting and identifying potential problems.

Application of efficient Hydraulic Shears

Automotive Industry: Widely used in the automotive industry for cutting sheet metal and other materials used in the production of cars and trucks. These machines are able to cut parts with high precision and speed, which is critical to producing high-quality cars. CNC shears are versatile and can be used to cut a variety of materials, including steel, aluminum, and other metals.

Aerospace Industry: For cutting materials used in aircraft production. The high precision and speed of these machines make them ideal for cutting complex parts used in aircraft and helicopter manufacturing.

Construction industry: Also used in the construction industry to cut materials for the production of buildings and other structures. These machines are able to cut steel and other metals with high precision, which is critical to creating strong and stable structures.

Manufacturing: Guillotine shear is used in many different manufacturing industries, including the production of appliances, electronics, and other consumer goods. These machines are able to cut material with high precision which is essential to produce high quality products.

Other applications: High-efficiency CNC shearing machines are also used in a wide range of other applications, including the production of signs, artwork, and other decorations.