Thank you for using the 40000W Fiber Laser Source Manual. We compile this document for you in order that the laser is used and maintained properly.

Please take time to read and understand this User’s Guide and familiarize yourself with the operating and maintenance instructions before you use the product. We strongly recommend that the operator read the Section 2 titled “Safety Information” prior to op erating the product.

This User’s Guide should stay with the product to provide you and all future users and owners of the product with important operating, safety and other information.

We identify the parts to which you need to pay special attention in the document with underscore. Please notice those information to prevent the unnecessary damages.

Table of Contents

Chapter 1: Characteristic Description

MFMC Series CW Fiber Laser products provide a wide range of wavelength from 1060nm to 1100nm.The lasers are water-cooled and maintenance-free and with a wall plug efficiency of more than 30% and deliver high efficiency, high reliability and high performance.

Maxphotonics' MFMC Series CW Fiber Laser Series are Class 4 laser products and are designed and tested with safety. By following this User Guide and applying sound laser safety practices, it will be a safe and reliable device.

Laser light exhibits unique characteristics that may pose safety hazards. Therefore, the laser light can’t be normally associated with other light sources, and all operators and people near the laser must be aware of these spec ial hazards.

In order to ensure the safe operation and optimal performance of the product, please follow all warnings and safety instructions in this guide during process of operation, maintenance and service and do not disassemble the device.

There are no serviceable parts, equipment or assemblies associated with this product for user. Lasers of unauthorized disassembly shall not be subject to warranty.

Chapter 2: General Safety Information

1-Safety Conventions

WARNING: Refers to a potential Electrical Hazard to human body. It requires a procedure that, if not correctly followed, may result in bodily harm to you and/or others.

Do not proceed beyond the WARNING sign until you completely understand and meet the required conditions.

CAUTION:Refers to a potential hazard on product. It requires a procedure that, if not correctly followed, may result in damage to the product or components. In order to ensure normal use of equipment, do not violate the requirement of the CAUTION sign.

NOTE :

◎ This device is classified as a high power Class IV laser instrument. It may emit up to 3000W average power from 1060nm to 1100nm. This level of light may cause damage to the eye and skin. Despite the radiation being invisible, the beam may cause irreversible damage to the retina. Laser safety eyewear is not provided with this instrument, but must be worn at all times while the laser is operational.

WARNING:Refers to a potential Laser Hazard.The symbol represents laser radiation. The symbol is pasted on laser output end.

NO SYMBOL

IMPORTANT:Refers to any information regarding the operation of the product. Please do not overlook this information.

NOTE :

◎ This device is classified as a high power Class IV laser instrument. It may emit up to 40/50KW average power from 1060nm to 1100nm. This level of light may cause damage to the eye and skin. Laser safety eyewear is not provided with this instrument, but must be worn at all times while the laser is operational.

Use appropriate laser safety eyewear when operating this device.

2-Laser Protection

1.Laser Protection Requirements

You must wear the safety protective glasses while operating the laser, and rationally select the safety protective glasses according to the lasing wavelength of the laser. If the device is a tunable laser or Raman product, it emits light over a range of wavelengths and the end user should confirm the laser safety eyewear used protects against light emitted by the device over its entire range of wavelength.

2.Laser Protective Equipment Suppliers

Maxphotonics recommends material or equipments provided by following laser protective equipment suppliers for you, including LaserVision USA, Kentek Corporation, Rochwell Laser Industries, etc. All the supplier information is provided by Maxphotonics only for the convenience to use, so Maxphotonics assumes no responsibility for any problem caused by using the products of abovementioned suppliers.

3-Reference Standard

Electromagnetic Compatibility Emission:

EN IEC 61000-6-4:2019

CISPR 16-2-1

CISPR 16-2-3

Anti-interference Performance on Electromagnetic Compatibility:

EN IEC 61000-6-2:2019

EN 61000-4-2:2009

EN 61000-4-3:2020

EN 61000-4-4:2012

EN 61000-4-5:2014+A1:2017

EN 61000-4-6:2014

EN 61000-4-11:2020

Laser Security:

EN 60825-1:2014+A11:2021

CDRH 21 CFR 1040.10

Electrical System Safety:

EN 60204-1:2018

NOTE:

◎ Performances of Maxphotonics MFMC laser meet the CE EMC certification requirements, the EMC requirements specified in "EMC Directive" of European market. Comply with the "EMC" standard EN 61000-6-4 emission and EN 61000- 6-2 anti-interference requirements.

◎ In accordance with relevant national standards and requirements, the laser must be classified according to its output power and laser wavelength. All MFMC-Series laser products with high power belongs to Class 4 products (according to section J,1040.10 (d) of Part Ⅱ , 21 CFR).

◎ According to the standards of EU, the equipment belongs to Class 4 instrument (according to article 9, EN 60825-1).

4-General Safety Instructions

1.Specular Reflection

There are often numerous secondary laser beams produced at various angles in the output port of the laser. These divergent beams are produced when the primary beam of laser reflects off a smooth surface, and they are called specular reflections. Although these secondary beams may be less powerful than the total power emitted from the primary beam, the intensity may be great enough to cause damage to the eyes and skin as well as surface of materials.

WARNING:

◎ You must exercise caution to avoid/minimize specular reflections as these laser radiations are invisible!

2.Safety Instructions of Accessories

The photosensitive elements integrated in laser-related optical accessories may be damaged by laser exposure, such as: video cameras, photomultipliers, and photodiodes. Attention should be paid to related device protection.

WARNING :

◎ The Maxphotonics MFMC laser light is strong enough to cut or weld metal, burn skin, clothing and paint. In addition, this light can ignite volatile substances such as alcohol, gasoline, ether and other solvents. During the operating process, the flammable materials around the laser must be isolated.

3.Optical Operating Instructions

We strongly recommend that you read the following procedures before operating the laser:

1.Never look directly into the laser output port when the power is turned on.

2.Avoid positioning the laser and all optical output components at eye level.

3.Equip with laser beam casing.

4. Make sure to remove the tail cover of the laser output head before the laser is turned on, otherwise it will cause irreversible damage to the laser fiber output

head.

5.Ensure that all personal protective equipment is suitable for the output power and wavelength range of the laser.

6.Use the laser in a room with access controlled by door interlocks. Post warning signs. Limit the safety areas to operate the laser.

7.Please do not operate the laser in darkened environments.

8.Do not turn on the laser without an optical coupling fiber or an optical output connector.

9.Carry out commissioning, calibration and focusing at low output power and then increase the output power gradually when the calibrating and focusing work is done.

10.Do not install or detach cutting heads or collimators when the laser is active.

11.Make sure that the laser is shut down and the power is off before you install or detach cutting heads or collimators.

12.If the equipment is operated in a manner not specified in this document, the protection devices and performance of the equipment may be impaired and the warranty will be voided.

CAUTION:

◎ The output of the laser is delivered through a lens with an anti-reflection coating. If the backward-stage light path of your laser has the optical lens, please strictly inspect the lens of the output head and the backward- stage lens of the laser, and ensure that there is no dust and any other impurity on the lens.

Please note that any macroscopic attachment may cause extreme damage to lens or burn the laser or any backward-stage light path equipment.

◎ For cleaning instructions of the lens, please refer to the "Optical Fiber Connector Inspection and Cleaning Guide".

◎ Hot or molten pieces of metal may be produced when the laser is under operation. Exercise caution if debris is produced in operation.

◎ When you carry out commissioning and calibration of the laser output, you must set the laser output at low power level and then gradually increase the output power during checking the quality of the light spot emitted from the laser via an infrared viewer.

WARNING:

◎ Make sure that the individual protective equipment meets the output power and wavelength range of the laser.

◎ Never look directly into the optical fiber or the collimator, and make sure you wear the safety protective glasses in each operation.

4.Electrical Operating Instructions

We strongly recommend that you read the following procedures before operating the laser:

1.The power supply voltage of the laser equipment is three-phase alternating current 360-440VAC, 3P+PE. The laser equipment needs to be properly grounded during installation and installation. The external cables of the cabinet must be placed in metal trunking or metal pipes during installation. Pay attention to the safety of electricity during use to prevent electric shock injury .

2.When disassembling the laser, turned off the power first . If electrical injury occurs, corrective measures should be taken to prevent secondary injury. The correct treatment process: turn off the power, release the personnel safely, call help, and accompany the injured.

3.The equipment does not have any part which can be maintained by operators, and all the maintenance operations must be finished by the professionals of Maxphotonics.

4.To prevent electrical shock, do not remove enclosure, detach the laser without permission and damage the relevant signs. Any product with unauthorized dismounting shall not be subject to warranty.

WARNING:

◎ The input voltage of the laser is triple-phase AC current (360-440VAC, 3P+3E), which may cause risk of electric shock. All the relevant cables and connection wires have potential hazards.

5.Environment Conditions and Precautions

For ensuring the safety of the laser working area, suitable enclosures shall be applied, including but not limited the laser safety signs and the interlocking devices. Corresponding operators must be trained and examined and know the normal safety specifications for operating the laser.Meanwhile, it is important that the output components shall not be installed at eye level.

Because of interaction of the laser and the metal material, the radiation of high level ultraviolet light or visible light may be produced. Make sure that the laser is provided with the protective cover to prevent the eyes or other parts of human bodies from damage by radiation.

We recommend that you comply with the following operating measures to prolong the service life of the laser:

1.In order to ensure a good operating environment of the laser, reduce the risk of condensation, reduce the probability of failure, and prolong the service life.

It is strongly recommended to configure the air-conditioned room of the laser in advance. The air-conditioned room should be spacious enough to facilitate internal maintenance. It can guarantee the minimum free space around the laser is 1.0m. If space is limited, the air-conditioned room needs to be designed to be easy to remove and install.

2.It is necessary to provide sufficient installation space for the air-cooled water cooler, and to ensure sufficient water cooler exhaust. The minimum free space of the top of the air-cooled water-cooled fan is 1.5m, and the side plate of the air filter is 1m away from the wall.

3.It is forbidden to place the air-cooled water-cooled machine in the laser air conditioned room. Because the air-cooled water-cooling machine discharges a lot of hot air, the room temperature will rise rapidly, and finally the heat dissipation will be poor, causing the water-cooling machine high-pressure alarm and laser condensation alarm.

4.Do not expose the laser to a high moisture environment.

5.The device is equipped with cooling fans. Make sure that there is sufficient airflow to cool the laser, any objects or debris that cover the ventilation holes must be removed at all times.

6.Operation at higher temperature will accelerate aging, increase threshold current and lower slop efficiency. If the device is overheated, stop operations and contact Maxphotonics.

7.Ensure that the work surface is properly vented. There may be gases, sparks and debris generated from the interaction between the laser and the work surface, and they could pose additional safety hazard.

CAUTION :

◎ The device may be damaged with incautious operation.

5-Additional Safety Information

For additional information regarding Laser Safety, please refer to the list below:

Laser Institute of America(LIA)

13501 Ingenuity Drive, Suite 128

Orlando,Florida 32826

Phone:407 380 1553,Fax: 407 380 5588

Toll Free:1 800 34 LASER

American National Standards Institute

ANSI Z136.1, American National Standard for the Safe Use of Lasers

(Available through LIA)

International Electro-technical Commission

IEC 60825-1,Edition 1.2

Center for Devices and Radiological Health

21 CFR 1040.10 - Performance Standards for Light-Emitting Products

US Department of Labor - OSHA

Publication 8-1.7 - Guidelines for Laser Safety and Hazard Assessment.

Laser Safety Equipment

Laurin Publishing

Laser safety equipment and Buyer’s Guides

Chapter 3: Product Description

1-Features

MFSC Series CW fiber lasers are compact and efficient and high-quality laser output lasers developed for industrial application. They are mainly applied to the fields of puching, welding, cutting, etc.

Main Features:

1、High-quality laser output

2、High power, high efficiency

3、High reliability, long service life

4、Compact, rugged package

5、Extension programming interface

Applications:

1、Industrial applications

2、Scientific research

2-Module Configuration

Maxphotonics offers many configurable modes. This manual will give complete instructions for all modes, please refer to section 6.3-6.6.

3-Laser Model Designation Codes

| M – F – S – C – XXX – XX 1 – 2 – 3 – 4 – 5 – 6 | ||

| 1 | Manufacturer’s code | M means Maxphotonics |

| 2 | Gain media of the laser | F means Fiber Laser |

| 3 | Laser mode | S means Single Mode |

| 4 | Laser state | C means Continue Wave |

| 5 | Maximum output power | XXXX W means the maximum output power of the laser |

| 6 | Additional message | Can be nul |

4–Certification

Maxphotonics certifies that this equipment has been thoroughly tested and inspected and meets published specifications prior to shipping. Upon receiving your equipment, check whether the packaging and accessories have been damaged in transit. If damage is apparent, please contact Maxphotonics immediately.

5- Front Panel Description

| Items | Function Description |

| ① MAIN SWITCH | 440VAC main powerswitch of laser |

| ② KEY SWITCH | Power switch of laser |

| ③ EMERGENCY STOP | Emergency stop |

| ④ START | Start laser (on-off signal of hardware) |

| ⑤ ALARM | Abnormal situation light of laser |

| ⑥ ACTIVE | Normal situation light of laser |

| ⑦ POWER | Power light of laser |

6-Back Panel Description

| Items | Function Description |

| ① CTRL | External control connector |

| ②ETHERNET | Network communication interface |

| ③WATER OUT | Water cooling output port (40kW&50kW 2 inches) |

| ④WATER IN | Water cooling input port (40kW&50kW 2 inches) |

| ⑤ AC380V | AC 360-440VAC input |

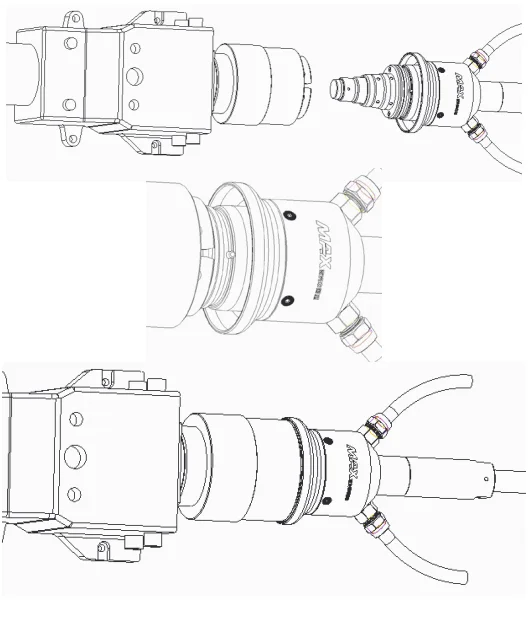

7-Optical Output Terminal

1.Optical Output Head

The optical fiber head is used corresponding to the protective window, and can be replaced after damage. Make sure to remove the black end cap on the LOE head before use, which is usually placed with the laser. Refer to Chapter 6 "Guidelines for Inspection and Cleaning of Optical Fiber Connectors" for protective window cleaning supplies and methods.

Optical Output Head (LOE-P、LOE-T ) MFMC-40000

Optical Output Head (LOE-S ) MFMC-50000

Chapter 4: Specification

1-Optical Characteristic Parameters

| Characteristics | Test Conditions | Min. | Nom. | Max | Unit |

| Operation Module | CW/Modulated | ||||

| Polarization | Random | ||||

| MFMC-40000 | 100% CW Output Power | 40000 | W | ||

| MFMC-50000 | 100% CW Output Power | 50000 | W | ||

| Tuning range of output power | 10 | 100 | % | ||

| Emission wavelength | 100% CW | 1070 | 1080 | 1090 | nm |

| Spectrum width(3dB) | 100% CW | 5 | 8 | nm | |

| Short-term power instability | 100% CW >1h | ±1 | ±2 | % | |

| Long-term power instability | 100% CW >24h | ±2 | ±3 | % | |

| Beam quality (BPP) | Output fiber core diameter 100um | 4 | 5.5 | mm x mrad | |

| Output fiber core diameter 150um | 5.5 | 6.5 | |||

| Output fiber core diameter 200um | 8 | 10 | |||

| Laser switching ON time | 150 | 200 | μs | ||

| Laser switching OFF time | 150 | 200 | μs | ||

| Modulation rate | 100% Output | 5 | KHz | ||

| Red guide laser power | 400 | uW | |||

| Feeding fiber cable length | 20 | m | |||

| Feeding fiber core size | 150 (100/200 can be customized | ||||

| Feeding fiber cable bending radius | 200 | ||||

| Output form | LOE | ||||

2-General Characteristic Parameters

| Characteristics | Test Conditions | Min. | Nom. | Max | Unit |

| Operating voltage | 360 | 400 | 440 | VAC | |

| Input Power | MFMC-40000 100% outpu | 132 | KW | ||

| MFMC-50000 100% output | 165 | ||||

| Operating ambient temperature | 10 | 25 | 40 | ℃ | |

| Operating ambient relative humidity | 10 | 80 | % | ||

| Cooling method | Water-cooling | ||||

| Cooling Medium | Pure water (above 0°C) / glycol antifreeze (below 0°C) | ||||

| Storage temperature | -10 | 25 | 60 | ℃ | |

| Dimensions | 1120*1100*1070(W*D*H) | mm | |||

| Weight | MFMC-40000 | 857(±10) | kg | ||

| MFMC-50000 | 936(±10) | ||||

3-Water Cooling Condition

| No. | Characteristics | Min. | Unit | |

| 1 | Cooling Method | Water Cooling | ||

| 2 | Water Temperature | winter 20 | summer 24 | ℃ |

| 3 | Hydraulic pressure | ≥ 4.5 | bar | |

| 4 | MFMC-40000 Water Flow Rate for laser cooling | ≥ 450 | L/min | |

| MFMC-50000 Water Flow Rate for laser cooling | ≥ 450 | |||

| 5 | MFMC-40000 Chiller Rated refrigeration capacity | ≥ 100 | KW | |

| MFMC-50000 Chiller Rated refrigeration capacity | ≥ 120 | |||

CAUTION :

◎ The Chiller needs to meet the requirements of the above table under the conditions of a circulating temperature of 40 ° C and an outlet temperature of 22 ° C.

◎ The above recommended water pressure requires the pressure drop of the main line Δp ≤ 0.5bar. If this value is exceeded, the main circuit water pressure should be increased accordingly.

◎ Cooling water and filter element, need to be replaced once a month; Winter (refers to the low temperature environment of 0 ° C and below) before the coming of the cooling water should be replaced with a volume ratio of 20% glycol solution (recommended brand Klein), and every two months, it is strictly prohibited to add excessive, low thermal conductivity of antifreeze, excessive addition is easy to cause poor heat dissipation. After the end of winter, it is necessary to replace the antifreeze back to distilled water and replace the filter element, and restore the maintenance frequency of once a month.

◎ When the ambient temperature of the equipment is lower than -15C, the water cooler with double system function must be used, and the cooling system must run uninterrupted.

4-LOE Water Cooling Condition

| NO | Cooling Method | Water pipe size requirement | Water Flow Rate (L/min) | Hydraulic pressure (bar) | Cooling Temperature (℃) |

| LOE | Water cooling | Ø12 | ≥4 | ≥4 | 28-30 |

CAUTION :

◎ The inner diameter of the outer optical path is greater than or equal to 8mm, and the length is less than or equal to 20m;

◎ The total length of the Φ12 pipeline connected to the LOE after switching from the external optical path is less than or equal to 1m;

◎ The LOE is connected in series with the cutting head;

◎ For the LOE scheme, the above recommended water pressure of the external optical path requires the pressure drop of the cutting head Δp≤3bar. If this value is exceeded, the water pressure of the external optical path should be correspondingly increased.

5-Installation Environment Requirements

1.The ambient air cleanliness grade requirement for optical fiber output head installation: 1000 or more stringent grade. Suggestions for Configuration of Standard Purification Workbench;

2.laser working environment temperature:10°C–40°C;

3.laser working environment humidity:10%-85%;

4.Avoid the condensation environment,the specific control standards are as follows:

NOTE :

◎ In order to ensure a good operating environment of the laser, to reduce the probability of failure due to condensation. We recommende to prepare an air conditioned room for the laser, so that the temperature in the air-conditioned room is ≤ 28 ° C, and the relative humidity is ≤ 50%. The water cooler should be placed in a different space from the laser. It is forbidden to place the water cooler in the air conditioned room;

◎ The laser head works at circulating temperature. In order to avoid condensation on the laser head, it is necessary to adjust the temperature of the cooling water of the external light path to room temperature. It is forbidden to cool the laser head with low-temperature cooling water.

6-Structural Layout

Laser Views.(Unit:mm)

Chapter 5: Operation Guide

1-Notice

CAUTION:

◎ Please refer to Chapter 4 "Specification" for proper electrical power.

◎ Please refer to Chapter 2 "General Safety Information" for inspecting whether the configuration environment of peripheral work of the laser meets the requirements.

2-Electrical Power Connection

The power supply voltage of the optical device is 360-440VAC for three-phase AC. Make sure that the live and ground wires are correctly connected according to the line mark. Poor contact of the ground wire may cause potential damage to the laser.

For ensuring the safety feature, Maxphotonics recommends you connect circuit breaker (air switch) and Stabilizer in series between the power supply unit and the laser. This electric power shall be in close proximity to the power supply unit of the equipment and can be easily disconnected.

If you have questions about wiring, please check the table below to determine your electrical specifications.

| Machine Type/W | Voltage /VAC | Rated current /A | Circuit breaker /A | Stabilizer /kW |

| MFSC-40000 | 400V±10%,3P+PE | 180 | 400A | ≥ 160 |

| MFSC-50000 | 400V±10%,3P+PE | 230 | 400A | ≥ 200 |

3-Extension Interface

WARNING:

◎ The output of laser control interface is not insulation from hazardous live part, it may result electric shock. Please make sure the equipment is power off when perform connection. Please make sure addition insulation shall be provided to prevent against electric shock after installation.

Laser CTRL interface is a high quality 55P multi-core air interface that provides a variety of signals for functional control of the laser, as described below:

| CTRL INTERFACE PIN | WIRE COLOR | FUNCTION DESCRIPTION | Signal Description |

| 1 | Orange Black | EX_LOCK_- | Dry contact input ON/OFF (ON-normal, OFF-fault) |

| 2 | Orange | EX_LOCK_+ | |

| 7 | Yellow and Black | CONTROL- | Dry contact input ON/OFF (ON-light, OFF-no light) |

| 8 | Yellow | CONTROL+ | |

| 10 | Green | EX_DA+ | Control laser output power (Analog signal 1V-10%, 10V- 100%) Common ground reference for analog signals |

| 11 | Green and White | EX_DA- | |

| 13 | Black and White | EX_M- | Control laser output power (Analog signal 1V-10%, 10V- 100%) Common ground reference for analog signals |

| 14 | Black | EX_M+ | |

| 15 | Red and White | EX_EN- | HIGH: 20VDC≤ V ≤24VDC LOW: 0VDC≤ V ≤5VDC 5mA≤ I ≤15mA (Enable :HIGH Disable :LOW) |

| 16 | Red | EX_EN+ | |

| 27 | Light Blue Black | EMGERNCY1_ INPUT- | HIGH: 20VDC≤ V ≤24VDC LOW: 0VDC≤ V ≤5VDC 5mA≤ I ≤15mA (Emergency stop: HIGH normal: LOW) |

| 28 | Light Blue Black | EMGERNCY1_ INPUT+ | |

| 31 | Brown and White | ERROR2 | open state when there is no fault, Short circuit when there is a fault |

| 32 | Brown and White | ERROR1 |

4-Start Step

WARNING:

◎ Make sure that all the electrical connections (including cooling water connections) are connected prior to use. All the connectors must be held steady with screws if possible.

◎ NEVER look directly into the output fiber and make sure that you wear the laser safety goggles when operating the product.

◎ Make sure all power is removed from the laser when wiring.

The startup process is as follows:

1. Start the chiller;

2. Remove the end cap of the collimator;

3. Check that the end face of the collimator is clean and free of debris;

4. Ensure that the emergency stop switch is turned on;

5. Set the MAIN SWITCH to the ON position;

6. Set the key switch on the front panel to the "ON" position;

7. Press the START button on the front panel.

5-Module Description

The working Modules of the laser are as follows:

1.Continuous Module: the emitted light is continuous and can be used for cutting;

2.Pulse Module: The emitted light is pulsed. When the pulse frequency is greater than a certain value, the actual application is used to control the average output power of the laser (pulse width adjustment, when the external control, the modulation signal corresponds to the Module);

3.External control: specific parameter settings through the board software interface.

External Control Signal Timing:

Timing specific description: Power analog quantity 0-10V signal is provided to the laser at least 20mS ahead of time, modulation and enable high level signal input, red light off, laser output. Enable high level signal reduction, red light output, laser off.

6-Software Description

(1) The installation program is stored in the U disk that is randomly packed (the software version is not updated regularly, subject to the official website announcement).

(2) Unzip NET4.6.rar to get NET46-x86-x64-AllOS-ENU.exe. Double-click to run to install the operating environment (Win10 system or systems with .NET 4.6 installed can skip this step).

(3) Decompress the G3-Series (Maxphotonics)-1.0.0.86.rar file to obtain G3-Series (Maxphotonics)-1.0.0.86.exe. Double-click to run to complete the monitoring software installation wizard (the one marked with “zh” is the Chinese wizard, and the one marked with “en” is the English wizard).

(4) After the installation is complete, a shortcut will appear on the desktop.

(5) Double-click the desktop shortcut to open the application and enter the following connection interface.

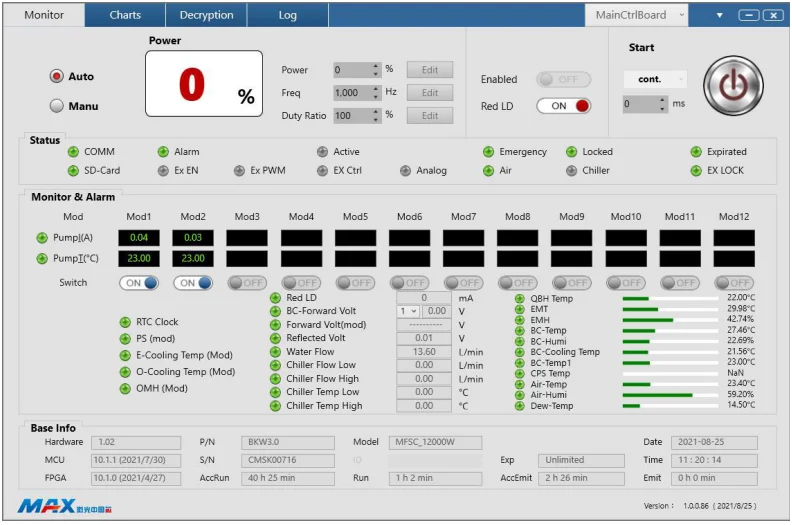

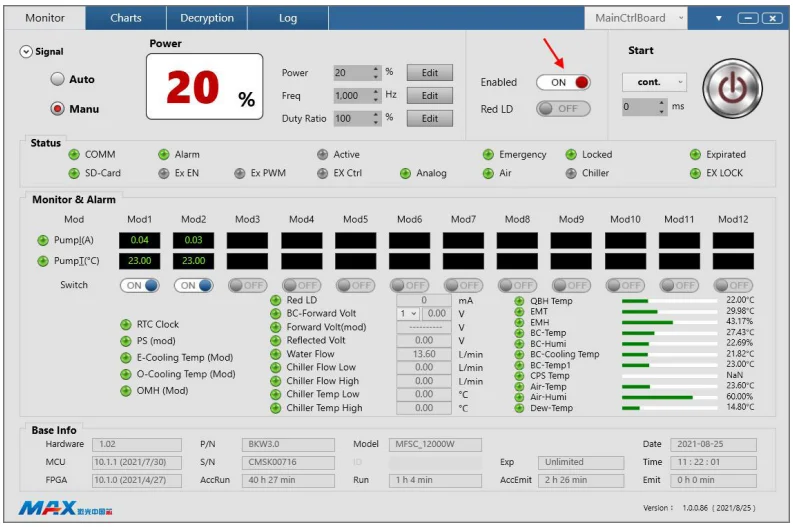

(6) Connect the laser and PC with the serial port cable that comes with the random connection, select the port number, log in to the laser, and enter the following monitoring interface. Note: When entering the monitoring interface,

the system selects the external control Module by default. External modulation/ enable/DA signal control.

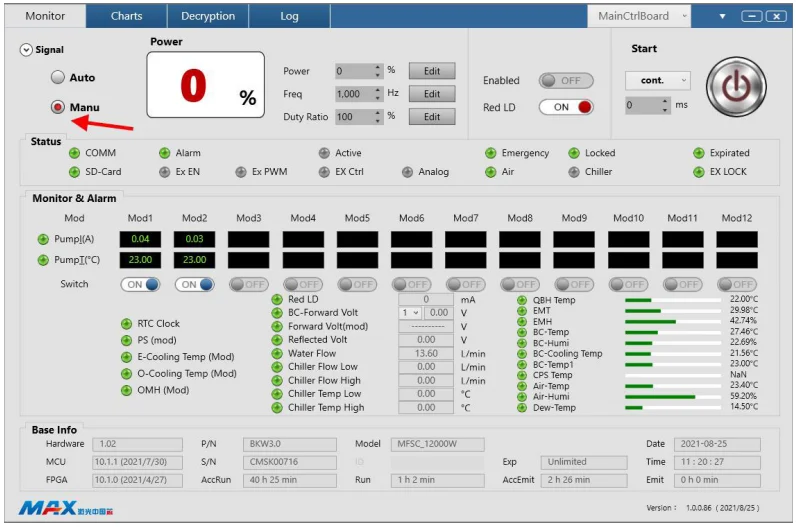

(7) The internal control Module controls the laser. (Click to select internal control Module).

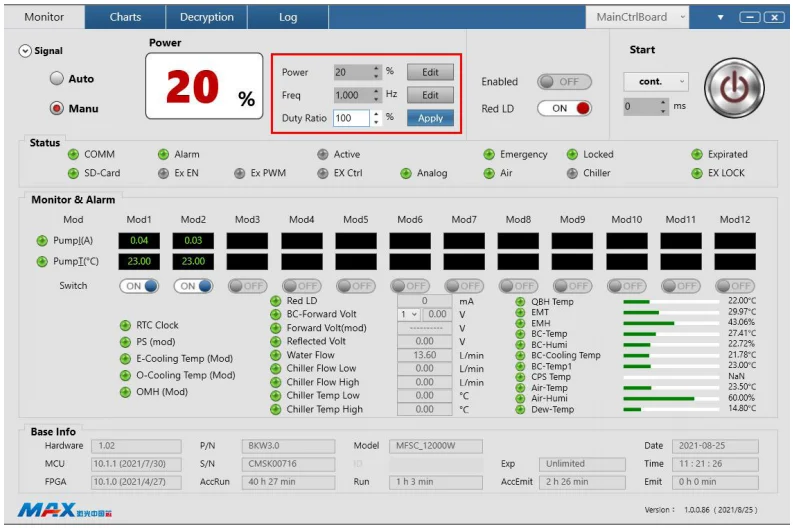

(8) Edit & set the laser power / frequency / duty cycle.

(9) Click to enable the host computer enable signal.

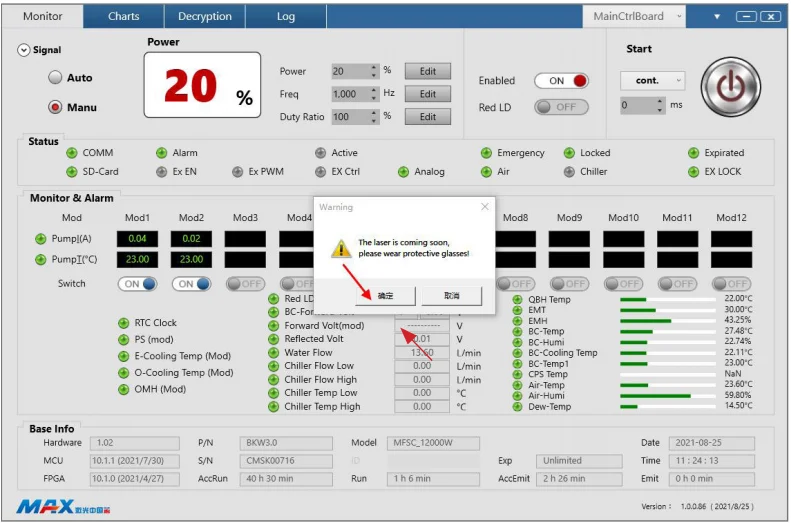

(10) Click to turn on the upper computer laser start button.

(11) Click “Yes” in the prompt box to turn on the laser.

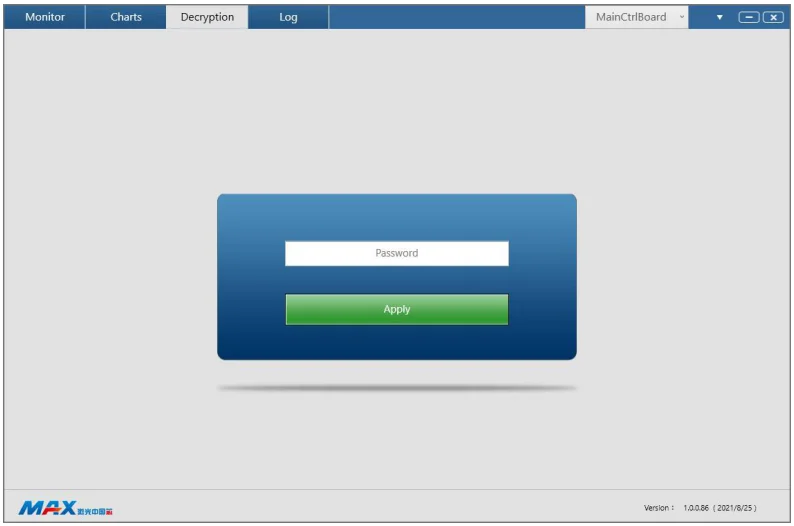

(12) Decryption interface.

Tip: For details on the software installation and usage instructions, refer to the software manual in the U disk.

7-Error Listing

The fault alarm points set by the laser include:

Forward light PD alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The laser inside does not detect the laser .

Solutions :

1.Restart the laser without laser ,check for red light. If there is no red light, please Contact Maxphotonics customer service;

2.If there is red light, please check if the relevant module can turn on the laser. Check whether the module DC power supply and voltage output is

normal.

Super strong backlight alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The beam combining module detects that the return light is too strong.

Solutions:

1 . Check the laser focus position;

2.Check if the material is placed horizontally;

3.Check if the material is ultra high-refective material;

4 . Check the material thickness exceeds the standard and cannot cut through the alarm;

5.Turn off the laser, pause for 3-5 minutes, restart the laser, and turn on the laser .

Pump temperature alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The laser module pump temperature is too high ,the temperature alarms.

Solutions:

Turn off the laser, check if the water cooler flow rate and water temperature are normal, and if the water pipe is blocked.After complete

the inspection, restart the laser and the laser returns to normal. If it can’t return to normal. Contact Maxphotonics customer service.

QBH installation alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The QBH output head contact in poor contact with the cutting head contact.

Solutions:

Turn off the laser, check the laser QBH output head and the cutting head, then reinstall.

Emergency stop alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes The emergency stop switch :is pressed.

Solutions:

Turn the emergency stop to normal and restart the laser.

Water fow alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The water-cooling machine is abnormal,results in the decrease of water fow.

Solutions:

Turn off the laser, check if the water cooler flow rate and water temperature are normal, if the water pipe is blocked. After the inspection is completed, restart the laser and the laser returns to normal.

Communication abnormal alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

There is no signal transmission between the single module communication line and the main module.

Solutions:

1.Check if the signal line connecting the single module and the main module is loose.

2.Check whether the single module can be powered on normally, whether there is red light, and whether the auxiliary power supply voltage output works normally.

Maximum current alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The single module pump source operating current exceeds the maximum limit.

Solutions:

1.Restart after the laser is turned off, check whether it is normal; if it is normal, use it normally;

2.If the maximum current alarm continues to occur, the drive MOS tube may break down in a single module. You need to turn off the laser immediately and contact Maxphotonics customer service.

Electric module water cooling plate alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The temperature of the water module is too high, and the temperature alarms.

Solutions:

Turn off the laser, check if the water cooler fow rate and water temperature are normal, and if the water pipe is blocked.After the inspection is completed restart the laser and the laser returns to normal. If it can’t return to normal, contact Maxphotonics customer service .

Combiner water cooling plate temperature alarm

Protective measures:

Stop supplying power to the main power and turned off the laser.

Possible causes:

The temperature of the water module is too high, and the temperature alarms.

Solutions:

Turn off the laser, check if the water cooler flow rate and water temperature are normal, and if the water pipe is blocked.After the inspection is completed, restart the laser and the laser returns to normal. If it can’t return to normal, contact Maxphotonics customer service.

NOTE:

◎ All laser alarm information, there will be corresponding display reminder on the monitoring software: please pay attention! If you have any questions, please contact our customer service staff.

Chapter 6: Service and Maintenance

1-Maintenance Instructions

Before connect the laser fiber connector, it is necessary to check the dust, dirt adhesion and damage of the end face. Using dirty or unclean fibre optic connectors can cause serious damage to the laser. Maxphotonics does not take any responsibility for laser damage caused by using unclean optical fiber connectors. If the optical fiber connector is tampered with privately, the equipment will no longer in guarantee.

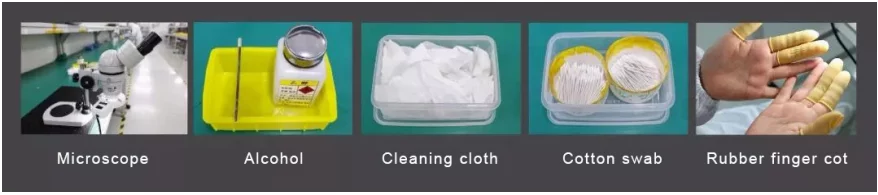

For cleaning a fiber connector you need the following materials:

1.Powder-free rubber gloves or fngerstall;

2.Lint free optical cleaning wipes and/or swabs;

3.Ahydrous ethanol (Optical level, purity >99.5%);

4.Compressed air (no oil, no water), or a wooden rod rolled with a double-layer adhesive tape;

5.Scale microscope (can be enlarged by 20 times and above).

IMPORTANT:

◎ It is imperative that you wear powder-free rubber gloves during this cleaning procedure! It is hereby stated that damage to the fiber connector can occur due to mishandling, the use of incorrect cleaning procedures, or chemicals for cleaning. This is not covered by the Maxphotonics’ warranty.

2-Appearance Inspection

1.Environmental requirements

LOE cleaning and installing cutting head shall be carried out in the clean room purification workbench,the dust-free grade requires 1000 grades, and the reference cleansing workbench as follow:

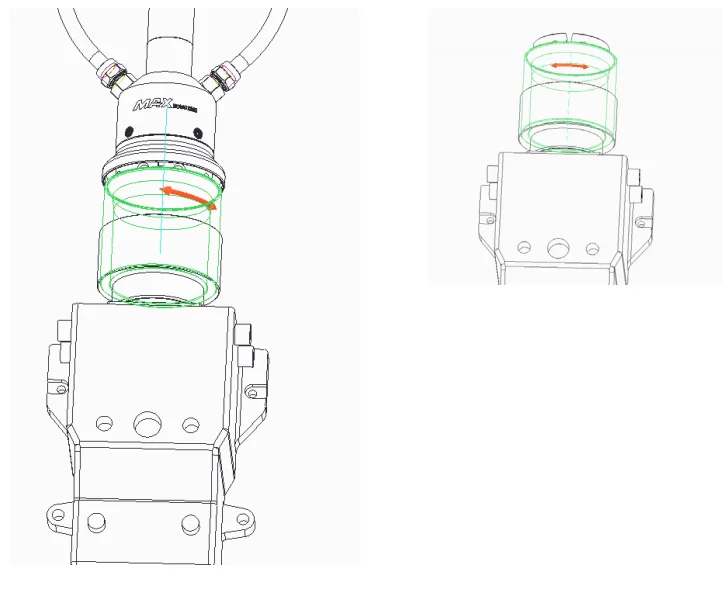

2.Operating Procedures

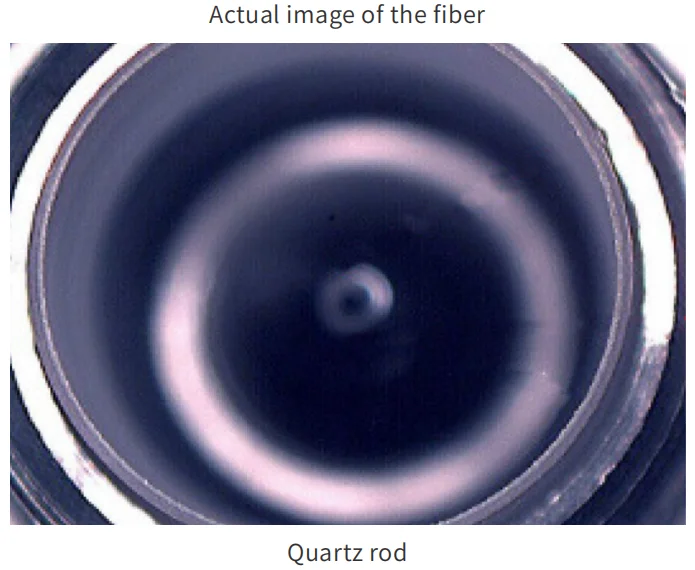

1.Switch off the laser power, and place the key switch on position of ”OFF”;

2.Rotate the black protective sleeve of the connector clockwise, place it under a 20x microscope and make the surface to be inspected clear, and check whether the appearance of the quartz rod meets the appearance standard. (referrence2.2.5);

3.If there is no dust particles, or the dust particles meet the appearance standards, put the black protective sleeve to return the connector;

4.If it is found that the dust particles exceed the appearance standard requirements, then clean them according to the requirements of step 3;

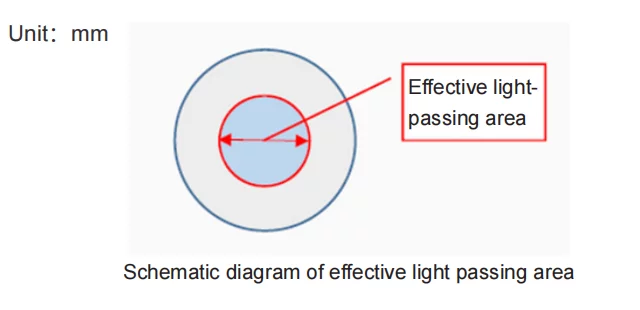

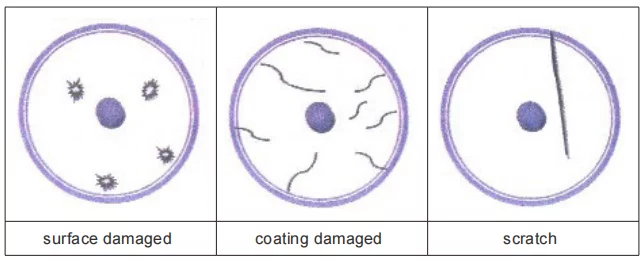

5.Appearance standards are shown in the table below:

| Power | Quartz rod | |

| Effective light-passing area (within φ3mm ) | Non-effective light-passing area (outside φ3mm ) | |

| 4000W-30KW | Pitting diameter: Not allowed Scratch width: Not allowed | Pitting diameter:≤ 0.1 Scratch width:≤ 0.005 |

| 2000W-4000W | Pitting diameter:≤ 0.05 Scratch width:≤ 0.002 | Pitting diameter:≤ 0.1 Scratch width:≤ 0.005 |

| Below 2000W (single Module | Pitting diameter:≤ 0.1 Scratch width:≤ 0.005 | Pitting diameter:≤ 0.1 Scratch width:≤ 0.01 |

3-Cleaning Procedures

1.Switch off the laser power, and place the key switch on position of ”OFF”

2.Cleaning protective lens with swabs

1.Rotate the black protective sleeve of the connector clockwise, place the inner or outer surface under a microscope of 20 times and make it clear. After careful observation, determine the specifc position of the dust particles, open the alcohol bottle cap and gently press the alcohol bottle mouth makes a small amount of alcohol ooze out, completely immerse the round cotton swab in alcohol, and then lightly swab the cotton swab to remove excess alcohol. Use a cotton swab to wipe the dust particles straight in the direction of the operator’s body.

The force should be light. After each wiping, the cotton swab can be rotated 180° and then wiped with the other side. After wiping for 2 times, the cotton swab is scrapped. Note that it is not allowed to circle. Or wipe back and forth to prevent dust particles from contaminating other areas or cotton swabs directly scratching the surface.After all cleaning, it is necessary to observe under the microscope again whether the surface is clean.

Endface may be damaged

2.Check the inner wall of the protective guide tube if there is obvious foreign matter with the microscope. If the foreign matter can be cleaned with a double sided glue stick, then use a cotton swab to wash the alcohol for further cleaning.

After the protective guide tube is dried, directly put on the connector.

3.Cleaning method for quartz rods

If fnd that the internal quartz rod is dusty or dirty, you can open the lens to clean it. The specifc steps are as follows:

1.Rotate the black protective sleeve, dust cap and protective lens at clockwise, first wipe the circumference and thread surface of the entire connector lens piece with an optical cleaning cloth and alcohol;

2.Put the quartz rod under a 20x microscope and make it clear. After careful observation, determine the specific location of the dust particles and clean according to the method of 3.2.1. For dust particles on the side of the fused quartz rod, use a pointed cotton swab to clean along the circumferential surface.

After all cleaning, confrm under the microscope whether it is clean, including the chamfered area. Finally, wrap it on the table with a non-woven fabric, and then continue other work to prevent the dust from contaminating the end face and side of the fused silica rod again;

3.Along the grain of the surface of the metal part, gently rotate the lens piece back to the metal part and confrm that it is in place. Place the black protective sleeve on the connector.

IMPROTANT:

◎ Do not reuse a lint-free optical wipe or swab;

◎ Do not touch the protective lens of the fber connector;

◎ Do not blow directly, or else new dirty will be brought;

◎ Do not touch the tip of the cleaning swab with your fngers;

◎ Cleaning is necessary before place the protective cover and s leeve;

◎ Never blow air directly at the surface, because you could imbed

contaminants into the surface. Always blow across the surface;

◎ If the fber connector could not be installed in optical system immediately, please cover it with the protective cap cleaned with compressed air;

◎ Be sure to operate in a Class 1000 clean environment

4-LOE Cutting Head Installationand Precautions

1.Installation steps

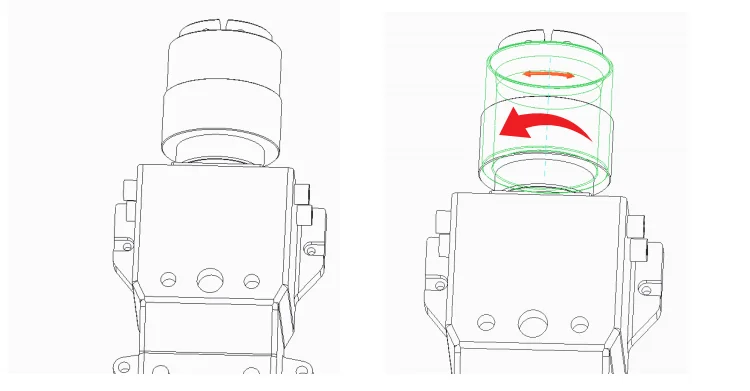

1.The LOE female head is fxed to the cutting head, and the LOE female head is rotated clockwise to the fxed position;

2.Insert the cleaned LOE male into the corresponding female fxed slot position.

To avoid dust pollution on the LOE end face and the inside of the cutting head, please ensure that the LOE and the cutting head are in the horizontal state;

3.Turn the male clockwise to a fxed position.

2.IMPORTANT

◎ LOE male head lens must be removed before inserting the female head;

◎ After removing the lens, it is necessary to clean the quartz rod and the thread of the fxed lens member;

◎ LOE male insert female head must be centered to prevent damage to the quartz rod;

◎ The entire operation process needs to be performed in a 100-level dust-free purifcation environment.

Chapter 7: Disassembly Guide

1-Unpacking Steps

The laser belongs to the precise valuables, so Maxphotonics recommends the following steps to unpack the packing box. Packing list is attached to the box.

After unpacking, please check the accessories according to the Packing List.

Please also save all the items after unpacking to prevent future transportation or storage.

The following picture shows the steps to remove the box:

1. Place the box containing the laser equipment in a stable place, such as a fat foor or a large platform.

2. We recommend that you use a fat blade screwdriver to pry the plastic clip, remove the plastic clasp, and then remove the top cover.

3. Lift the top beam up and remove it, taking care not to scratch the top cable.

4. Remove the top foam and pick up the accessory.

5. Follow the second step to remove the four side panels, in the order of long edges -> short sides -> another short side -> another long side.

6. Remove the tensioning strap and PE bag, pay attention to tightening direction of the ratchet and tightening the strap opening method:

- Press and hold the stop circlip

- Rotating and tightening the gallows 180°

- Pull out the straps forcefully

7. Please use forklift or crane to lift the laser and move to the designated position

When customers need to repack, please refer to the following steps.

1. Put the pallet and clean it up, then place the tensioning strap and pass the tensioning strap through the bottom slots on both sides of the pallet.

2. Use a forklift to fork the product to a certain height, move the pallet to the bottom, and position the product slowly. When placing the product, pay attention to the direction of the product as shown.

3. Put on the PE bag, tighten the tensioning belt, and separate the paper corners between the product and the tensioning belt. There are 4 paper corners. Pay attention to the use of the tension band:

- Locate the slot shaft position and pass the strap from below the slot shaft;

- Tighten through the strap and turn back into the slot axis position;

- The straps are worn out and

- Tightened the straps;

- Shake the handle back and forth to

4. Assemble the side panel, insert the plastic buckle into the slot and fasten it. The assembly sequence is: long side -> short side -> another short side -> another long side.

5. Assemble the top support and the top foam, taking care that the top support is to hang the side panels.

6. Assemble the top cover and fasten all the plastic buckles.

NOTE:

◎ If you fnd any damage to the outer packaging or internal components after received the product, please contact Maxphotonics or your local representative immediately.

◎ The laser is equipped with a dehumidifer. When the ambient temperature and humidity are too high, the laser will have a process to prevent dew condensation and dehumidifcation (about 30 minutes). The condensed water will fow out from the bottom outlet of the cabinet.

◎ When turned off the laser, the water cooler should also be turned off to prevent condensation from occurring due to excessive temperature difference.

RECOMMENDATION:

Change the operating temperature or humidity of the laser to keep the laser away from the dew point. (such as installing the laser in an air-conditioned room)

| No. | Names of fttings | Description | Unit | Quantity |

| 1 | Fiber-optic laser | MFSC-XXX | Pc | 1 |

| 2 | USB to RS232 serial cable | BLT | 1 | |

| 3 | Cable | BLT | 1 | |

| 4 | Key | Pc | 2 | |

| 5 | U Disk | Pc | 1 | |

| 6 | Clamp | Pc | 2 | |

| 7 | RS232 (external) | BLT | 1 | |

| 8 | Client external control adapter cable | BLT | 1 | |

| 9 | External control line | BLT | 1 | |

| 10 | Continuous external control interface insurance board PCBA | Pc | 1 | |

| 11 | Superfne dust-free cloth (2*2) | Pc | 6 | |

| 12 | QBH water pipe sample tube | BLT | 1 | |

| 13 | Laser water pipe sample tube | BLT | 1 | |

| 14 | Pointed cotton swab | Bag | 1 | |

| 15 | Round head cotton swab | Bag | 1 |

Chapter 8: Service and Maintenance

1-Maintenance Notes

CAUTION :

◎ No operator serviceable parts inside. Refer all servicing to qualified Maxphotonics personnel.

◎ For ensuring that the repairs or replacement within the warranty scope can be carried out, and perfectly maintaining your interests, please submit application to the Maxphotonics or the local representative after finding the faults. Upon receiving our authorization, you need to pack the product in a suitable package and return it.

◎ You should keep the proof when finding any damage after receiving the product, so as to claim the rights to shippers.

IMPORTANT :

◎ Do not send any product to Maxphotonics without RMA,otherwise it will be returned according to rejection. The resulting losses are borne by the customer; in order to ensure the timely processing of the returning machine, the customer must ship the faulty machine to the designated address of Maxphotonics.

If the product is beyond the warranty period or the warranty scope, customers shall be responsible for the repairing cost.The specifc charges include spare parts costs, labor service fees, and travel, accommodation and other expenses incurred by on-site services.

CHANGE :

◎ We have the rights to change any design or structure of our product, and the information is subject to change without notice.

2-Service Statements

More problems regarding the safety, set-up, operation or maintenance please reading this “User Guide” carefully and fowing the operation steps stictly. Please call the Customer Service Department for other questions.