ماكينة الضغط والثني CNC - سلسلة PBS

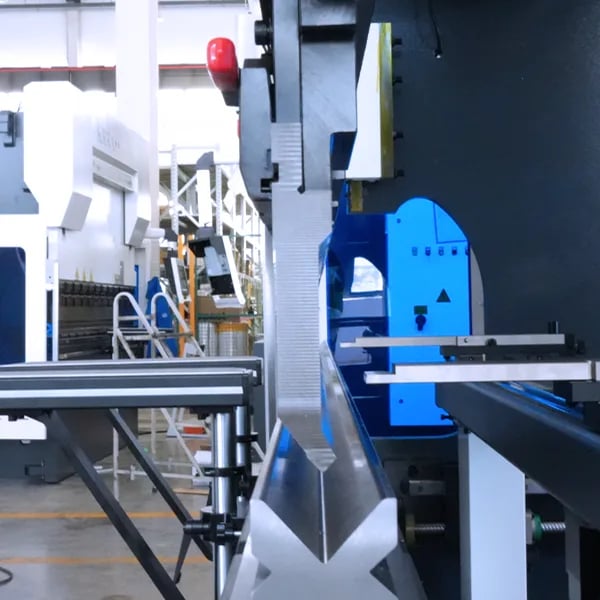

آلة ثني CNC ذات المحرك الرئيسي من سلسلة PBS، وهي آلة ثني CNC ميسورة التكلفة، وعدد مذهل من الميزات والخيارات. بأسعار تنافسية مع عناصر تحكم رسومية متقدمة DELEM DA-66T أو DA-69T قادرة على التعامل مع الرسومات ثلاثية الأبعاد، سلسلة High Standard هي خيارك الأول في تكنولوجيا ثني CNC.

تواصل معنا

إذا كان لديك أي أسئلة، يرجى الاتصال بنا، وسوف نرد عليك في أقرب وقت ممكن.

تواصل معنا

إذا كان لديك أي أسئلة، يرجى الاتصال بنا، وسوف نرد عليك في أقرب وقت ممكن.

مكبس فرامل CNC بمحرك سيرفو رئيسي - سلسلة PBS

الميزات والتكوين

الميزات الرئيسية

التكوين المستورد، مستقر وموثوق به

إطار عالي القوة مع لوحة سميكة ومواد كافية ونظام تثبيت خلفي عالي الدقة

المحور القياسي 4+1 (X، Y1، Y2، R+W)

التحكم في الحلقة المغلقة وتعويض الانحراف الميكانيكي التلقائي لطاولة العمل

عالمي ذكي عالي الجودة مكابس الضغط CNC

تقدم مجموعة PBS تنوعًا كبيرًا وتحتوي على عدد كبير من الملحقات والمعدات الاختيارية

التكوين القياسي

وحدة التحكم ديليم DA-53T

- التنقل باللمس باستخدام "المفتاح الساخن"

- شاشة TFT ملونة عالية الدقة مقاس 10.1 بوصة

- حتى 4 محاور (Y1،Y2 + 2 محاور مساعدة)

- التحكم في التتويج

- مكتبة الأدوات / المواد / المنتجات

- التحكم في السيرفو ومحول التردد

- خوارزميات التحكم المتقدمة على المحور Y للصمامات ذات الحلقة المغلقة والحلقة المفتوحة.

جهاز تعويض تشوه الحلق من النوع C

يمكن لمسطرة الشبكة Fagor قياس التشوه الصغير الناتج عن قوة انحناء أداة الماكينة بدقة، ثم تعويض ردود الفعل، لضمان دقة ثني الألواح من أي سمك ومواد.

شنايدر الكتريك

تتمتع المكونات الكهربائية عالية الجودة بالقدرة على الأداء الجيد حتى عندما يكون مصدر الكهرباء غير مستقر، ويمكن للعملاء الحصول بسهولة على قطع الغيار في أي مكان في العالم.

محرك سيرفو ذو محور X

بالإضافة إلى ذلك، تشمل مزايا محركات المؤازرة ما يلي:

- موثوقية عالية: موثوقة للغاية

- نسبة عالية من عزم الدوران إلى القصور الذاتي: يمكن أن توفر ما يصل إلى 50% عزم دوران أكبر في العديد من التطبيقات

- دقة عالية: يمكنه تشغيل المواضع وعزم الدوران والسرعات والإمساك بها وتسريعها بدقة في أجزاء من الثانية

محرك سيرفو على المحور R

تتمتع محركات المؤازرة بالعديد من المزايا، بما في ذلك:

- كفاءة عالية: يمكن الاقتراب من 90% بأحمال خفيفة

- طاقة انتاج عالية: بالنسبة لحجمها ووزنها

- التحكم في الحلقة المغلقة: يضمن دقة أكبر

- التشغيل الهادئ: صوت ضجيج قليل

نظام هيدروليكي عالي الأداء

تحسين أداء الآلة

67%

نظام صمام المؤازرة عالي الأداء:

ريكسروث / هاوي، ألمانيا

التحكم المتزامن في حلقة مغلقة بالكامل،

آلة تعمل بسرعة عالية وثبات

وظيفة ECO الجديدة للسيرفو الهجين

تعمل شركة KRRASS® على تعزيز سياسة صديقة للبيئة، وبالتالي تتميز جميع معداتنا بوظيفة Hybrid ECO. يوفر نظام تحديد المواقع الهجين لدينا الدقة في أي موضع. وهذا يجعل مكبس CNC الخاص بك أكثر توفيرًا للطاقة وأكثر كفاءة.

مزايا توفير الطاقة

- ديناميكية عالية لإنتاجية أعلى للماكينة.

- الامتثال لتوجيهات الاتحاد الأوروبي.

- طاقة أقل من أجل آلة خضراء.

- تم تخفيض مستوى ضغط الصوت إلى 50 ديسيبل.

- محرك المؤازرة، مع التحكم في السرعة بحلقة مغلقة.

- كفاءة الطاقة تصل إلى 35 % مقارنة بالأنظمة التقليدية.

- تعتبر تكلفة التشغيل ضئيلة بسبب استهلاك الطاقة المنخفض. وبالتالي، فهي توفر مزايا للمستخدم من حيث الكفاءة العالية وتكلفة التشغيل المنخفضة.

مضخة الزيت الهيدروليكية

تحظى مضخة الزيت بتقدير كبير لأدائها الاستثنائي، والمعروفة بتشغيلها الهادئ وطول عمرها المذهل، مما يجعلها خيارًا موثوقًا به لتطبيقات مختلفة.

دليل خطي لولبي كروي على المحور X

- الدقة: توفر مسامير الكرة دقة متزايدة واستهلاكًا أقل للطاقة ومتطلبات صيانة أقل.

- الاستجابة: توفر براغي الكرة حركة سلسة بشكل استثنائي.

- الاحتكاك: تعتمد مسامير الكرة على إعادة تدوير الكرات لتقليل الاحتكاك بدلاً من مواد التشحيم.

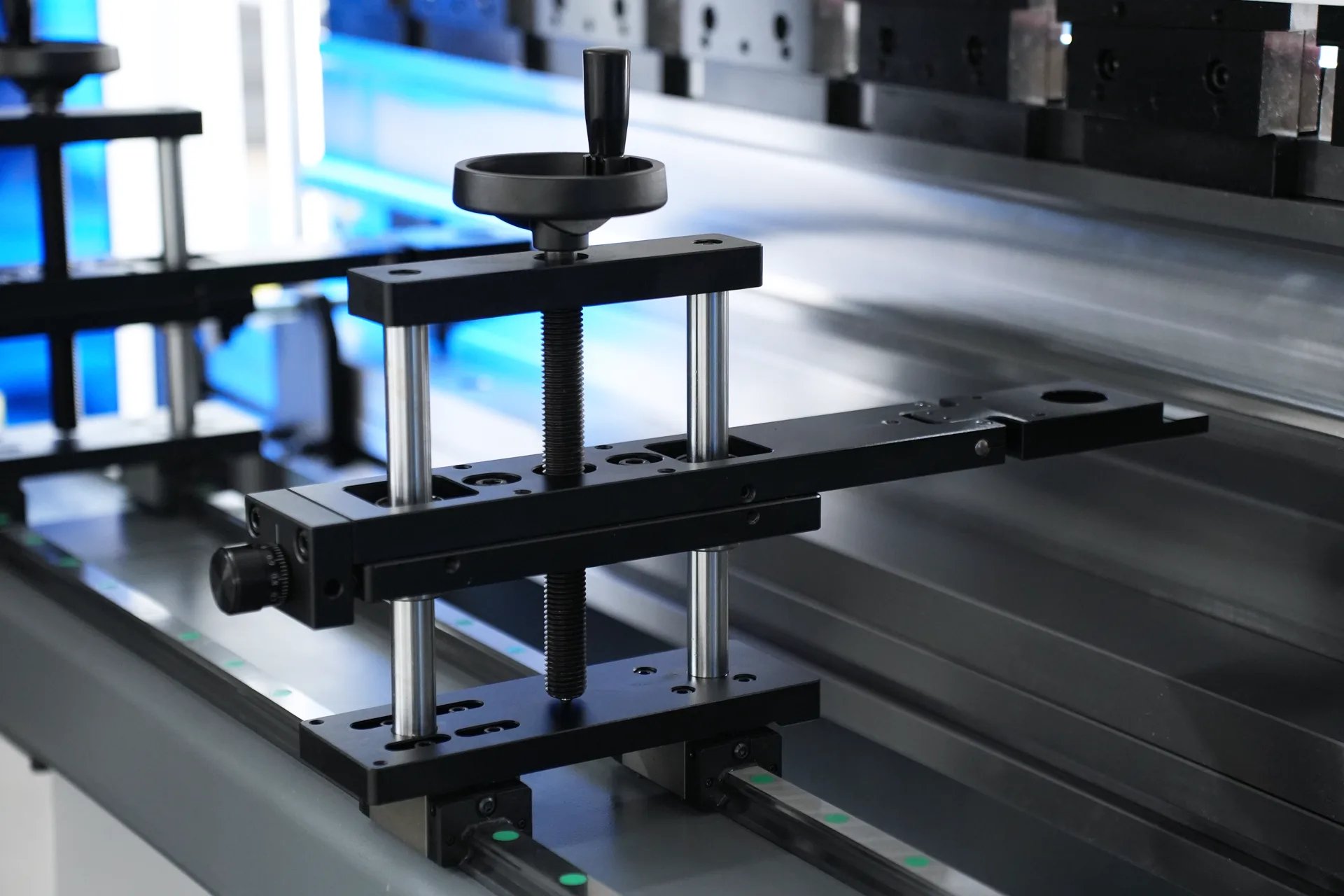

أداة إيقاف الإصبع الخلفية

تعني خاصية التوقف الخلفي عالية الدقة أن العملاء يمكنهم إدخال الحجم في النظام وفقًا لأبعاد المنتج، ويمكن وضعه بدقة تصل إلى 0.01 مم.

تم تصميم العارضة المتقاطعة بقضبان توجيه خطية مزدوجة، مما يسمح لأصابع الحجب بالتحرك إلى اليسار واليمين على طولها.

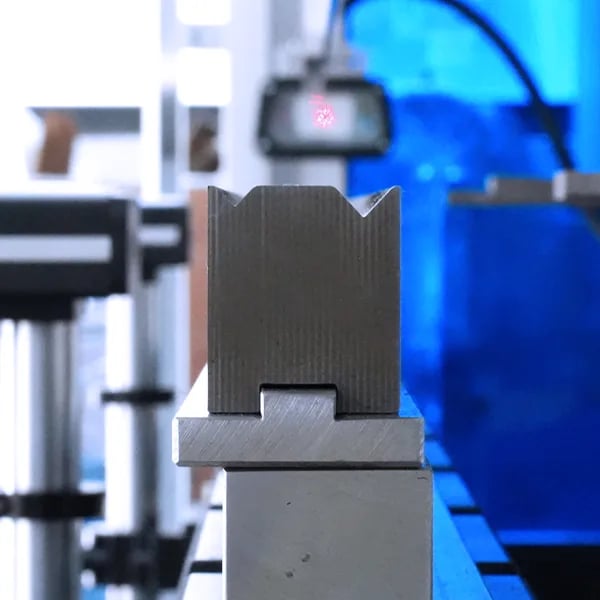

جهاز التثبيت السريع الدقيق

من الملائم تثبيت القالب العلوي بسرعة، مما يقلل من كثافة العمالة ويحسن كفاءة الإنتاج. يتميز الطراز العملي بمزايا الدقة العالية، والتثبيت السهل، وعدم فك القالب، وعدم سقوط الأداة، وما إلى ذلك.

نظام التتويج الآلي CNC

تحتوي طاولة العمل المنخفضة على وحدة تعويض التتويج التلقائية؛ يتم ضبط كمية التعويض تلقائيًا بواسطة نظام CNC، مع ضمان نفس زاوية الانحناء على الطول الكامل.

يعتمد طاولة العمل على تصميم خاص، مما يقلل بشكل فعال من كمية التشوه التاج للأداة السفلية.

دعم المواد الأمامية

يمكن رفع وخفض دعامة المواد الأمامية بحرية. عندما تحتاج إلى ثني صفائح معدنية أكبر، يمكن أن تساعدك بشكل فعال في تقليل عبء العمل.

مفتاح الدواسة

تم تصميم مفتاح القدم من العلامة التجارية الكورية الجنوبية ليكون قابلاً للحركة، مما يسمح بإيقاف الماكينة فورًا باستخدام زر الطوارئ. تعمل هذه الميزة على تعزيز السلامة والتحكم في التشغيل.

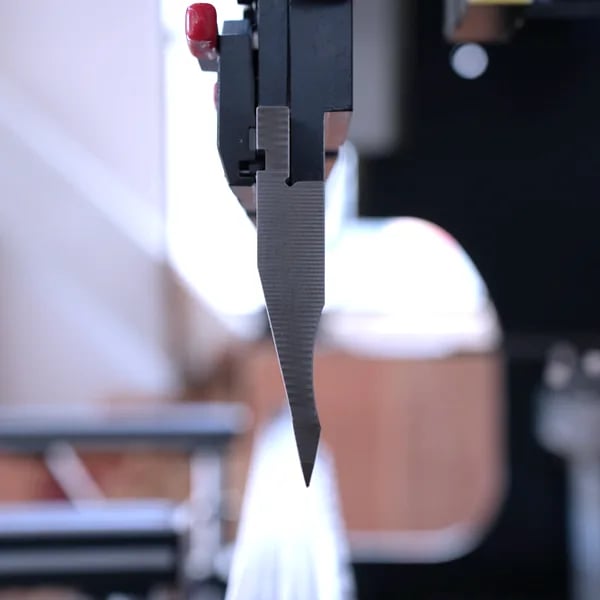

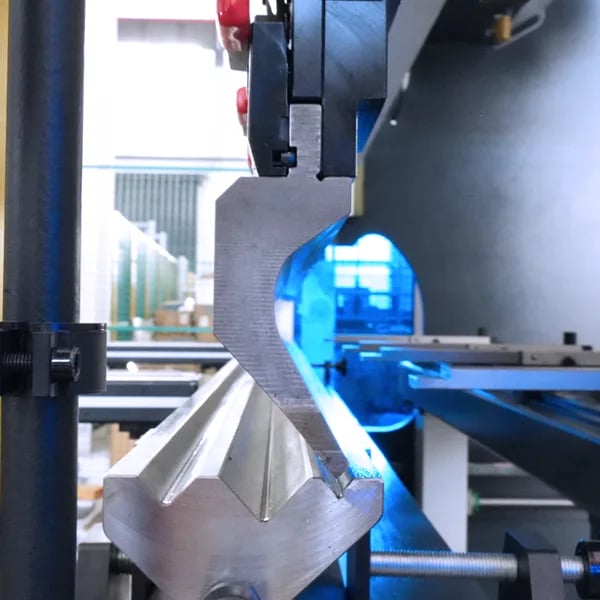

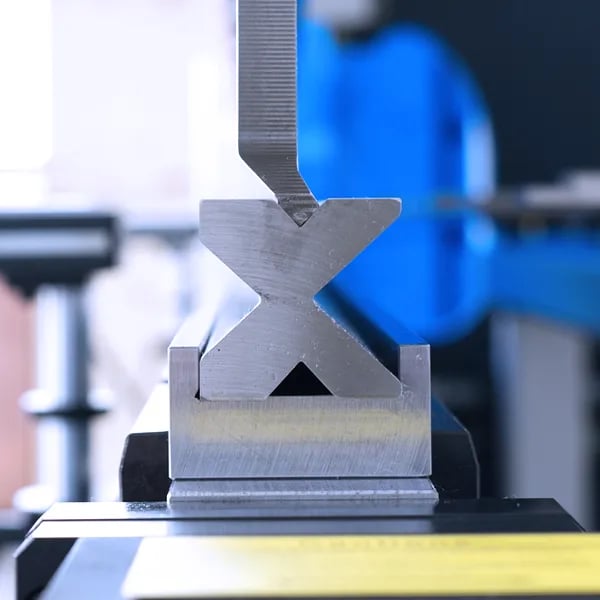

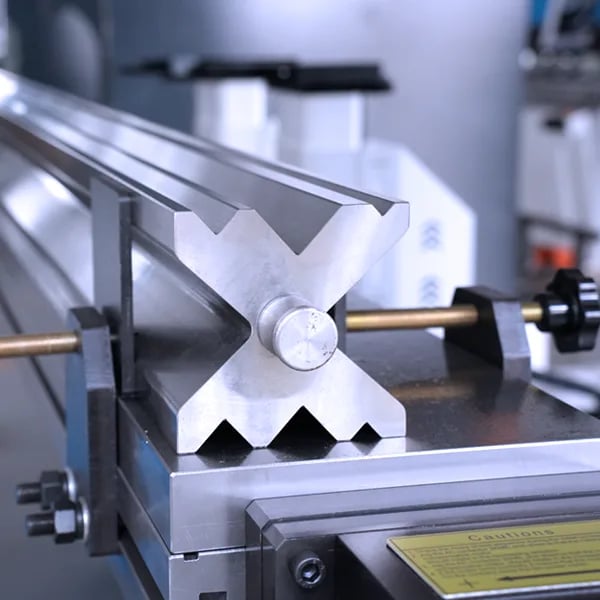

اللكمات والقوالب

ستكون مكابس الثقب والقوالب الهيدروليكية أحد أهم المواضيع التي نناقشها قبل تقديم الطلب. سيتم إكمال أي شكل انحناء بمجموعة مناسبة من المكابس والقوالب. يمكننا توفير الأدوات المناسبة وفقًا لمتطلبات الانحناء المختلفة للعملاء.

نظام تحكم CNC قوي ونظام قياس خلفي

العديد من التقنيات المبتكرة الحاصلة على براءة اختراع

تتوفر مجموعة متنوعة من المقاييس الخلفية

وحدة التحكم CNC:

وحدة تحكم Delem DA-58Tx

- برمجة شاشة اللمس الرسومية ثنائية الأبعاد

- شاشة TFT ملونة عالية الدقة مقاس 18.5 بوصة

- حساب تسلسل الانحناء

- التحكم في التتويج

- التحكم في السيرفو ومحول التردد

- خوارزميات التحكم المتقدمة على المحور Y للصمامات ذات الحلقة المغلقة والحلقة المفتوحة.

- USB، واجهة محيطية

- برنامج Profile-T غير المتصل بالإنترنت

وحدة التحكم ديليم DA-66S

- وضع برمجة شاشة اللمس الرسومية ثنائية الأبعاد

- تمثيل الآلة ثلاثية الأبعاد في المحاكاة والإنتاج

- شاشة TFT ملونة عالية الدقة مقاس 24 بوصة

- توافق Delem Modusys (قابلية التوسع والتكيف مع الوحدة النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة تصحيح وانحناء المستشعر

- برنامج Profile-SL غير المتصل بالإنترنت

وحدة التحكم ديليم DA-69S

- وضع برمجة شاشة اللمس الرسومية ثلاثية الأبعاد وثنائية الأبعاد

- التصور ثلاثي الأبعاد، بما في ذلك التمثيل الآلي ثلاثي الأبعاد، في المحاكاة والإنتاج

- شاشة TFT ملونة عالية الدقة مقاس 24 بوصة

- توافق Delem Modusys (قابلية التوسع والتكيف مع الوحدة النمطية)

- USB، واجهة محيطية

- دعم التطبيقات المخصصة للمستخدم ضمن بيئة تعدد المهام الخاصة بعنصر التحكم

- واجهة تصحيح وانحناء المستشعر

- برنامج Profile-S3D غير المتصل بالإنترنت

حل المقياس الخلفي:

مقياس خلفي 3+1 محور

يمكن تعديل ارتفاع مقياس الظهر يدويًا، مما يسهل عليك تشغيل بعض الملحقات المخصصة عند استخدام آلة ثني الصفائح المعدنية.

مقياس خلفي 4+1 محور

يمكن للمقياس الخلفي عالي الدقة مع وظيفة الضبط الدقيق ضمان أن عملية الانحناء الخاصة بك أكثر كفاءة وأن قطعة العمل تنحني بدقة أكبر.

مقياس خلفي 4+1+2 محور

يتم التحكم في المحورين الكهربائيين Z1 وZ2 بشكل مستقل، مما يجعل التشغيل أكثر ملاءمة. أصابع توقف مخصصة موسعة وممتدة، إطار دعم الأصابع مع دليل خطي مزدوج، تلبي متطلباتك.

مقياس خلفي 6+1 محور *

يعتمد المحور X على لولب كروي وخطي، مما يضمن دقة مزامنة عالية وعمرًا طويلاً للغاية. أصابع توقف مخصصة موسعة وممتدة، إطار دعم الأصابع مع دليل خطي مزدوج، تلبية متطلباتك.

مقياس خلفي بمحور 7+1 *

يتحرك المحور X للأمام والخلف، ويتحرك المحور R للأعلى وللأسفل، ويتحرك المحور Z1 والمحور Z2 بإصبعين إلى اليسار واليمين، ويتحرك المحور X1 بإصبع إلى الأمام والخلف، ويتم التحكم في المحاور الخمسة بواسطة وحدة تحكم CNc لتحديد موضع الارتباط بدقة.

مقياس خلفي 8+1 محور *

يتضمن المقياس الخلفي قاعدة كبيرة ذات صلابة عالية، وآلية دفع المحور X، وآلية دفع المحور R وآلية دفع المحور z؛ وفقًا لاحتياجات أجزاء المعالجة، يمكن تعديل إصبع السدادة تلقائيًا إلى الموضع الدقيق المطلوب لضمان تحديد موضع دقيق لقطعة العمل، وذلك لمعالجة قطعة العمل المؤهلة.

* إذا اخترت تكوين مقياس الخلفية 6+1 محور، أو 7+1 محور، أو 8+1 محور، فيجب أن تكون مجهزًا بجهاز تحكم DA-66S أو DA-69S.

تكوين اختياري آخر

حماية الليزر

يمكن لجهاز حماية الليزر DSP المستورد من إيطاليا توفير الحماية الشاملة والفعالة لسلامة مكابح الضغط وحماية السلامة الشخصية للمشغل.

نظام كشف الزاوية بالليزر

إن استخدام نظام قياس زاوية الليزر يمكن أن يضمن زاوية انحناء قطعة العمل مستقرة ويحسن كفاءة واستقرار التشغيل الآلي.

أدوات التثبيت والتثبيت من WlLA

يتم تثبيت القالب العلوي هيدروليكيًا، ويتم التحكم في عملية التثبيت والفك تلقائيًا عن طريق الكهرباء. قوة التثبيت كبيرة وموثوقة، كما أن تغيير القالب سهل وفعال.

جهاز تثبيت هيدروليكي للقالب السفلي، يتم التحكم في عملية التثبيت والفك تلقائيًا عن طريق الكهرباء، ويصبح تغيير القالب أسهل وأكثر كفاءة.

دعامات المتابعين الأمامية CNC

عندما يتم ثني قطعة العمل، يمكن للوحة الدعم تحقيق وظيفة الدوران التالية. يتم حساب الزاوية والسرعة التالية والتحكم فيها تلقائيًا بواسطة نظام Nc، ويمكنها التحرك يسارًا ويمينًا على طول قضيب التوجيه الخطي.

نظام تخزين الأدوات WILA

للإجابة على احتياجات مكابح الضغط المخصصة، تقدم شركة Krrass حلول تخزين أدوات مبتكرة مخصصة لمكابح الضغط القياسية والأدوات المخصصة: محطة الأدوات (تخزين الأدوات المعيارية ونظام التغيير) وخزائن الأدوات القياسية.

وحدة معالجة الانحناء المرنة

وفقًا لاحتياجات الإنتاج والمعالجة الخاصة بك، نقدم حلول أتمتة مرنة للصفائح المعدنية.

الأدوات (اختياري)

تواصل معنا

إذا كان لديك أي أسئلة، يرجى الاتصال بنا، وسوف نرد عليك في أقرب وقت ممكن.

بريد إلكتروني

واتساب

+86 189 5208 7956

موقع

نانجينغ، جيانغسو، الصين