In the sheet metal fabrication industry, the bending operation is often a bottleneck in the production process. Panel bending technology can help metal fabricators streamline this step, significantly boosting manufacturing capacity and speed. When the application and annual usage align well with the part mix, the ROI for a CNC panel bender can be realized quickly.

Table of Contents

Types of Panel Bender

Panel benders, also known as panel bending machines or press brakes, come in various types, each designed to suit specific manufacturing needs and requirements. Here are some common types of panel benders:

Manual Panel Benders: These are basic panel bending machines operated manually by the operator. They are suitable for small-scale operations or applications where precision and speed are not critical factors.

Hydraulic Press Brakes: Hydraulic press brakes use hydraulic cylinders to exert force on the bending tool, allowing for precise and powerful bending of metal sheets. They are suitable for a wide range of applications and offer high accuracy and repeatability.

Servo-Electric Press Brakes: These press brakes use servo motors instead of hydraulic systems to drive the bending mechanism. They offer high precision, energy efficiency, and low maintenance requirements. Servo-electric press brakes are often preferred for applications requiring high-speed bending and intricate shapes.

CNC (Computer Numerical Control) Press Brakes: CNC press brakes are equipped with computerized controls that allow for precise control over the bending process. Operators can program the machine to bend metal sheets into complex shapes with high accuracy and repeatability. CNC press brakes are highly versatile and suitable for a wide range of applications.

Tandem Press Brakes: Tandem press brakes consist of multiple press brake machines operated in tandem to increase bending capacity and efficiency. They are used for bending large and heavy metal sheets or for high-volume production.

Box and Pan Brakes: Box and pan brakes, also known as finger brakes, are specialized bending machines used for bending metal sheets into boxes, pans, and other complex shapes with straight sides. They feature adjustable fingers that allow for precise bending along multiple axes.

Panel Folding Machines: Panel folding machines are designed specifically for folding metal sheets along straight lines to create sharp bends. They are often used in industries such as HVAC, roofing, and automotive for manufacturing panels and enclosures.

What Is CNC Paner Bender

A CNC panel bender is an advanced, fully automated machine that utilizes computer programs to bend metal panels into precise shapes. CNC, which stands for Computer Numerical Control, represents the height of panel bending technology. These machines are especially suited for industries that demand high precision and customization, such as automotive, aerospace, and construction. CNC panel benders can work with various metal materials, thicknesses, and shapes, producing large volumes of high-quality products while minimizing material waste.

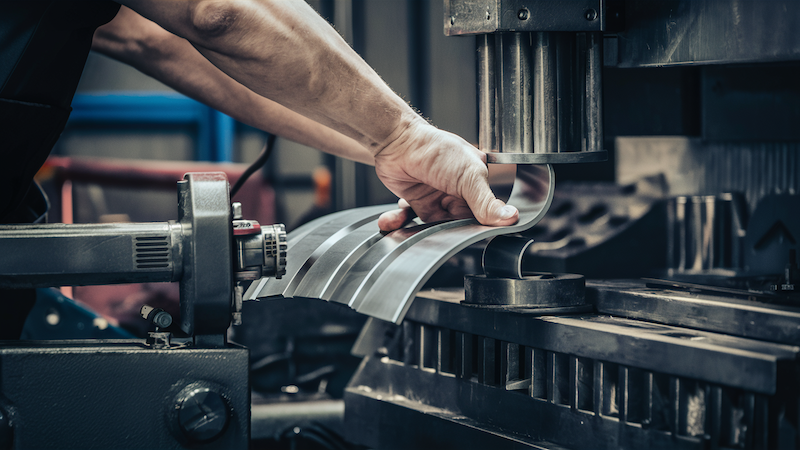

CNC panel benders operate by clamping a metal sheet in place and then using a mechanical or hydraulic system to bend the metal along a predetermined axis. The control system functions as the machine's brain, managing the bending process with exceptional precision and efficiency. Advanced software allows operators to set detailed parameters, including bend sequences and angles, and to store programs for future use. This digital infrastructure ensures consistency and accuracy in production runs.

Similar to CNC folding machines, CNC panel benders specialize in bending large and thin metal sheets. They provide excellent accuracy and repeatability, making them suitable for high-volume production. Considerations for CNC panel benders include the number of bending stations, tooling options, and the level of automation.

How Does CNC Panel Bender Work

A CNC panel bender functions by securing a metal sheet between an upper and lower beam. The machine then performs a series of precise upward and downward movements with these beams to bend the metal along predefined lines. This bending process is managed by advanced software, which guarantees precision and consistency.

The essential components of a CNC panel bender include the clamping beams, bending blades, and a control unit. The clamping beams secure the metal sheet, while the bending blades move to create the desired bends. The control unit enables the operator to program specific bending patterns and angles, ensuring that each piece is manufactured to exact specifications.

How Can Panel Bending Enhance Bending Efficiency and Production Speed?

It is widely recognized that the average setup time on a press brake ranges from 15 to 30 minutes, which has led to the development of automatic tool changeover systems by many press brake manufacturers. This lengthy setup time often forces fabricators to overproduce to justify the setup costs, resulting in excess inventory, work-in-process (WIP), or even misplaced or discarded parts.

Panel benders, on the other hand, offer much quicker setup times because they can use common tooling to handle various part geometries and material thicknesses. Operators do not need to physically change tools between jobs. Instead, they simply slide the clamping tools to new positions as needed. This can be done manually in about five minutes, or with an automatic tool changer, which reduces the setup time to approximately 90 seconds.

This reduction in setup time makes panel benders ideal for fabricators implementing lean manufacturing principles—producing only what is needed, when it is needed, and minimizing WIP.

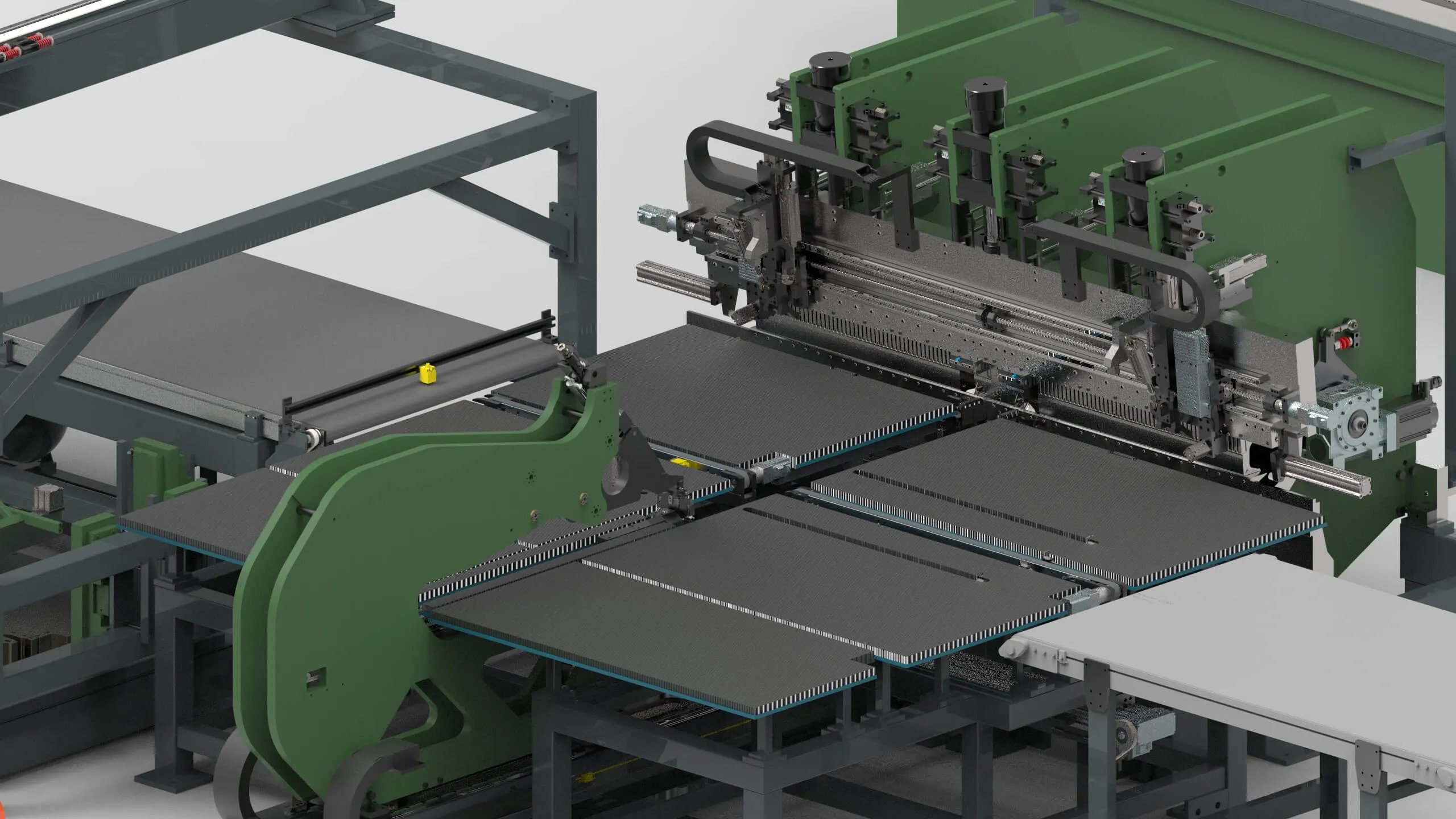

Panel bending technology operates on the transfer line principle, ensuring parts are continuously moving forward as different stations work simultaneously. By using a modular approach, fabricators can combine multiple bending units to further decrease bending cycle times.

This method is particularly effective for achieving a 1-1 ratio between blanking and bending operations. Once this balanced ratio is reached, the blanking and bending processes can be integrated into a single, continuous line, ensuring that no machine or process is left waiting. Additionally, the process can be optimized by directly feeding finished parts to the assembly area, thereby eliminating extra handling and WIP.

How Can Panel Bending Simplify the Entire Production Process?

It is important to note that panel bending addresses not only the bending bottleneck but downstream operations as well. An analysis of the different processes in an average sheet metal fabrication shop shows that welding and assembly are by far the most expensive processes on the shop floor, with one of the main culprits being poor fit-up. How much time does the welding operator have to spend trying to make the part fit in the welding fixture rather than weld? How often does the assembly operator struggle to get the parts to fit together? This happens more often than not.

Panel benders can help streamline these downstream operations by producing parts with high flatness and accuracy. Superior flatness is achieved because unlike a press brake with dynamic crowning, minimal tonnage is placed across the bending line.

Accuracy improvements are attributable to how the part is referenced. It is referenced from a single datum point, eliminating what is known as tolerance error accumulation. When making multiple bends on a press brake, the operator often is required to gauge from previously bent flanges. This opens the opportunity for the tolerance error to accumulate, leaving the welding or assembly operator as the last line of defense to correct the problem. A quick overview of the welding and assembly departments is a good place to start when evaluating the bending process.

How Can a Wider Range of Part Geometries Be Processed?

As with any technology, panel bending comes with its own set of challenges. Many fabricators are eager to adopt this technology, only to discover they don't have the right mix of parts to fully utilize the machine's efficiency. Complex part geometries or narrow parts often pose difficulties for panel bending, especially if the machine cannot handle these types of parts with its standard tooling and manipulator design.

The concept of the multitool panel bender emerged from extensive research aimed at expanding capabilities so that more varied part geometries could be processed without the need for additional manual tooling changes.

A key feature of the multitool panel bender is its integrated console, which can accommodate multiple bending tools. This allows it to bend complex part profiles that were previously unsuitable for panel bending. Additionally, a manipulator device on the backside of the multitool panel bender enables the processing of narrow channel-type parts, which were challenging for traditional panel benders.

The multitool panel bender can handle mild steel sheet thicknesses ranging from 0.020 to 0.118 inches and lengths up to 13 feet for a single machine, or up to 26 feet when using two machines in tandem. Other features, such as moving tools, visual inspection devices, grippers, and custom tools, can be integrated into the final system.

Designed to be user-friendly, the multitool panel bender is easy to program, control, and maintain. It operates on electric drives, ensuring low energy consumption while delivering high performance.

When Do You Need A CNC Panel Bender?

Panel benders are ideally suited for handling large, boxy, flat, straight, and rectangular parts that are challenging for a single person to bend and manage using a press brake, especially when dealing with parts that require a high-quality finish.

Panel bending is commonly utilized for forming:

- Appliances such as refrigerators

- Electrical appliances like electric cabinets and lighting fixtures

- HVAC equipment

- Construction components, including panels, doors, elevators, cable trays, platforms, and profiles

- Metal furniture for commercial kitchens, offices, storage units, and lockers

- Truck trailers

This technology is particularly beneficial for bending cosmetic or appearance-critical parts. A brush table supports the part from underneath, and the bending tool’s interpolated movement in the X and Y axes maintains a single point of contact with the flange during the bending process, significantly minimizing scratching and marring.

Panel bending technology brings numerous advantages to modern sheet metal manufacturing. Although there are some limitations regarding the types of parts panel benders can process, they can be the most efficient bending method when the application is appropriate.

How to Understand Panel Bender CNC System

Components of a Panel Bender CNC System

A Panel Bender CNC system integrates key components crucial for efficient metal bending:

The Clamping Mechanism securely holds metal sheets in place during bending, ensuring stability and precision throughout operations. Bending Blades adjust dynamically to achieve precise bends as programmed, enhancing the machine's versatility in handling diverse bending tasks. The Control Unit acts as the central hub, managing all CNC operations from programming intricate bending sequences to ensuring consistent and accurate results with minimal manual intervention. An intuitive Software Interface empowers operators to input specific bending parameters, monitor operations in real-time, and seamlessly manage machine functions, optimizing productivity and customization in metal fabrication processes.

Operation Principles

Programming involves setting precise bend angles, sequences, and dimensions within the CNC system, enabling operators to tailor bending processes to exact specifications. This capability streamlines production and enhances flexibility.

Automation plays a crucial role in CNC panel benders by automating the bending process, minimizing manual labor, and ensuring consistent results batch after batch. This automation not only boosts efficiency but also reduces the risk of human error.

Precision is a hallmark of CNC panel benders, allowing them to achieve high levels of accuracy and repeatability in bending operations. This precision is essential for maintaining quality standards and meeting tight tolerances in metal fabrication.

Capabilities

Understanding material handling capabilities involves knowing the range of metals and thicknesses that the CNC system can effectively handle, ensuring compatibility with various manufacturing needs.

The system's capability for complex bends allows it to perform intricate shapes and bends with minimal setup time, enhancing operational efficiency and versatility in metal fabrication tasks.

Assessing production efficiency highlights how the CNC system improves throughput by automating processes and reducing material waste, ultimately optimizing manufacturing operations for increased productivity and cost-effectiveness.

Maintenance and Training

Ensuring optimal performance of a CNC panel bender involves two critical aspects: maintenance and operator training.

Regular maintenance tasks are essential to keep the CNC system in prime condition. This includes routine checks, lubrication of moving parts, and inspection of electrical components to prevent breakdowns and ensure longevity.

Equally important is comprehensive operator training. Operators must be proficient in all aspects of using the CNC system, from programming specific parameters and troubleshooting issues to adhering to safety protocols. Proper training not only maximizes operational efficiency but also minimizes downtime and ensures safe working practices in the manufacturing environment

How to Choose the Right CNC Panel Bender?

Choosing the right CNC panel bender involves considering several factors to ensure it meets your specific manufacturing needs and requirements. Here's a step-by-step guide to help you make the right decision:

Assess Your Bending Requirements:

Determine the type and thickness of materials you will be bending (e.g., steel, aluminum, stainless steel).

Consider the size and complexity of the parts you need to produce, including the required bending angles and tolerances.

Evaluate Machine Capacity:

Look for a CNC panel bender for sale that can handle the size and thickness of your typical workpieces.

Consider factors such as bending length, tonnage (bending force), and maximum bending angle.

Consider Automation and Productivity Features:

Assess the level of automation offered by the CNC panel bender, including features like automatic tool changing, material handling systems, and robotic integration.

Evaluate productivity-enhancing features such as fast setup times, quick tool changeovers, and high-speed bending capabilities.

Review Precision and Accuracy:

Look for automatic panel benders with advanced control systems and precision mechanisms to ensure accurate bending results.

Consider features such as crowning systems for compensating for deflection and maintaining uniform bending across the length of the part.

Examine Software and Programming Capabilities:

Evaluate the user interface and programming software provided with the panel bending machine.

Look for intuitive programming interfaces, simulation tools for verifying bending sequences, and compatibility with common CAD/CAM software.

Assess Reliability and Maintenance Requirements:

Research the reputation of the manufacturer and the reliability of their CNC panel benders.

Consider factors such as machine uptime, maintenance requirements, and availability of spare parts and technical support.

Technical Parameters of Fully-automatic CNC Panel Bender Machine

| Model | RAS-1500/RAS-2000/RAS-2500 |

|---|---|

| Minimum continuous bending speed | 0.5s/knife |

| Bending thickness | 201 stainless steel 0.8mm, 304 stainless steel 1.0mm cold steel 1.2mm, aluminum steel 1.6mm |

| Max bending length(mm) | 1500/2000/2500 |

| Max bending height(mm) | 170 |

| Min molding size of four sides (mm) | 280*280 |

| Bending angle | 0-180 |

| Max feeding speed(m/min) | 120 |

Final Thought

Choosing the right CNC machine for sheet metal bending is a crucial decision that significantly impacts production efficiency and success. Key factors to consider include material compatibility, bending requirements, precision, cost, and maintenance.

Krrass CNC machines offer advanced technology and high precision, making them ideal for efficient and accurate sheet metal bending operations. With continued advancements in CNC technology, the future of sheet metal bending looks promising. Embrace the power of Krrass CNC machines to unlock potential for enhanced production capabilities and operational success.