Hybrid-Abkantpresse - PBS-Serie

Die Hybrid-Abkantpresse PBE ist eine Maschine der Spitzenklasse mit einem dynamischen Hybrid-Servoantrieb und benutzerfreundlicher Steuerung, die sich durch Präzision und leisen Betrieb auszeichnet. Ausgestattet mit fortschrittlichen Sicherheitsfunktionen zeichnet sie sich bei der Herstellung komplexer Teile aus.

Hybrid-Abkantpresse - PBE-Serie

Funktionen und Konfiguration

Hauptmerkmale

Importierte Konfiguration, stabil und zuverlässig

Hochfester Rahmen mit dicker Platte und ausreichend Material Hochpräzises hinteres Haltesystem

Standardmäßige 4+1-Achsen (X, Y1, Y2, R+W)

Regelung mit geschlossenem Regelkreis und automatischer mechanischer Kompensation der Durchbiegung des Arbeitstisches

Universell einsetzbare intelligente High-End- Hybrid-Abkantpresse

Die PBE-Reihe bietet eine hohe Vielseitigkeit und verfügt über eine große Anzahl optionaler Zubehörteile und Ausrüstungen

Standardkonfiguration

Delem DA-53T Controller

- „Hotkey“-Touch-Navigation

- 10,1" hochauflösendes Farb-TFT

- Bis zu 4 Achsen (Y1, Y2 + 2 Hilfsachsen)

- Bombierungskontrolle

- Werkzeug-/Material-/Produktbibliothek

- Servo- und Frequenzumrichtersteuerung

- Erweiterte Y-Achsen-Steuerungsalgorithmen für Ventile mit geschlossenem und offenem Regelkreis.

C-Typ-Kehlenverformungskompensationsgerät

Das Gitterlineal von Fagor kann kleine Verformungen, die durch die Biegekraft einer Werkzeugmaschine verursacht werden, genau messen und anschließend eine Rückkopplungskompensation durchführen, um die Biegegenauigkeit von Platten beliebiger Dicke und aus jedem Material sicherzustellen.

Schneider Electric

Hochwertige elektrische Komponenten funktionieren auch bei instabiler Stromversorgung einwandfrei und Kunden können sich überall auf der Welt problemlos Ersatzteile besorgen.

X-Achsen-Servomotor

Zu den Vorteilen von Servomotoren zählen außerdem:

- Hohe Zuverlässigkeit: Äußerst zuverlässig

- Hohes Drehmoment-Trägheits-Verhältnis: Kann in vielen Anwendungen bis zu 50% mehr Drehmoment liefern

- Hohe Präzision: Kann Positionen, Drehmoment und Geschwindigkeiten in Sekundenbruchteilen präzise ansteuern, halten und beschleunigen

R-Achsen-Servomotor

Servomotoren bieten mehrere Vorteile, darunter:

- Hohe Effizienz: Kann sich bei geringer Belastung dem 90% nähern

- Hohe Ausgangsleistung: Im Verhältnis zu ihrer Größe und ihrem Gewicht

- Regelung: Sorgt für höhere Genauigkeit

- Leiser Betrieb: Wenig Geräusche

Hochleistungs-Hydrauliksystem

Verbesserte Maschinenleistung

67%

Hochleistungs-Servoventilsystem:

REXROTH / HAWE, Deutschland

Vollständig geschlossene Synchronsteuerung,

Maschine arbeitet mit hoher Geschwindigkeit und stabil

ePrAX® Hybrid-Servosystem

Das ePrAX®-Steuerungs-Hybridsystem ist ein innovativer Servo-Antrieb für Hybrid-Abkantpressen. Dank des bürstenlosen Motors können wir die Bewegung des Stößels mit einem Minimum an Öl und Energie präzise steuern.

Verbesserung der Energieeffizienz um bis zu 73 % im Vergleich zu herkömmlichen Systemen.

Energiesparvorteil

- Hohe Dynamik für eine höhere Produktivität der Maschine.

- Einhaltung der EU-Richtlinien.

- Weniger Energie für eine umweltfreundliche Maschine.

- Abgesenkter Schalldruckpegel um 50 dB.

- Der Servomotor mit Drehzahlregelung.

- Energieeffizienz von bis zu 35 % im Vergleich zu herkömmlichen Systemen.

- Die Betriebskosten sind aufgrund des geringen Energieverbrauchs minimal. Somit bietet es dem Benutzer Vorteile durch hohe Effizienz und niedrige Betriebskosten.

Maximale Ausdauer!

Es biegt und biegt und biegt sich …

Schneller und effizienter!

Geschwindigkeit | Mehr als 40% Öl sparen

Geringerer Energieverbrauch!

Qualität | Höhere Betriebsgeschwindigkeiten

Mehr Laser-on-Time

Sparen Sie Zeit und Kosten…

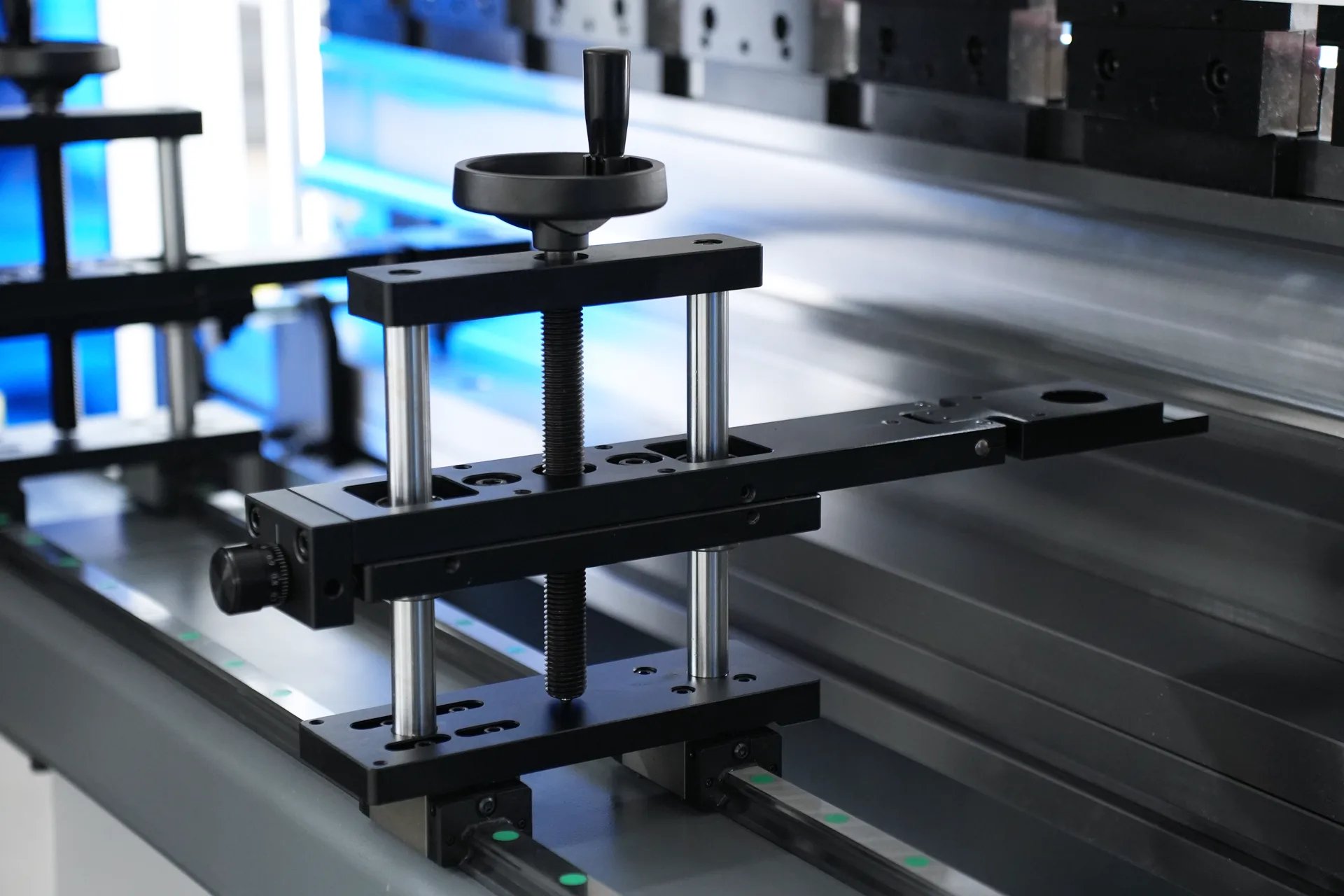

Linearführung der Kugelumlaufspindel der X-Achse

- Präzision: Kugelumlaufspindeln bieten höhere Präzision, reduzierten Energieverbrauch und geringeren Wartungsaufwand.

- Reaktionsfähigkeit: Kugelumlaufspindeln sorgen für außergewöhnlich gleichmäßige Bewegungen.

- Reibung: Kugelumlaufspindeln nutzen zur Reibungsreduzierung anstelle von Schmiermitteln Kugelumlaufkugeln.

Fingerstopper hinten

Dank des hochpräzisen Anschlags können Kunden die Größe entsprechend den Produktabmessungen in das System eingeben und sie mit einer Genauigkeit von 0,01 mm positionieren.

Der Querträger ist mit doppelten linearen Führungsschienen ausgestattet, sodass sich die Sperrfinger entlang dieser sowohl nach links als auch nach rechts bewegen können.

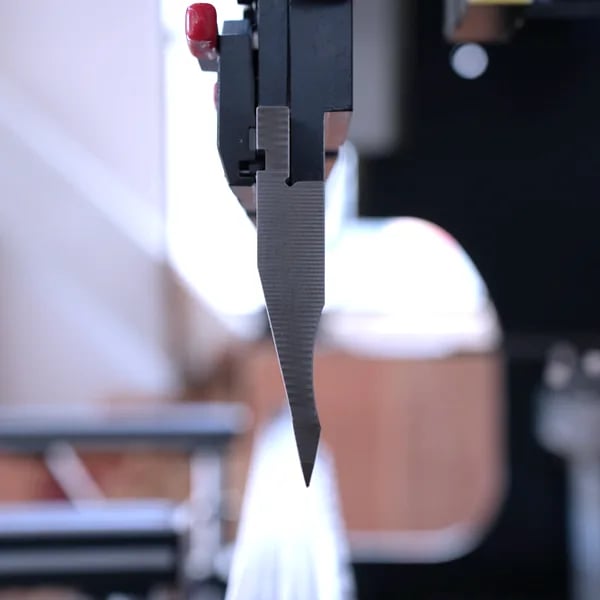

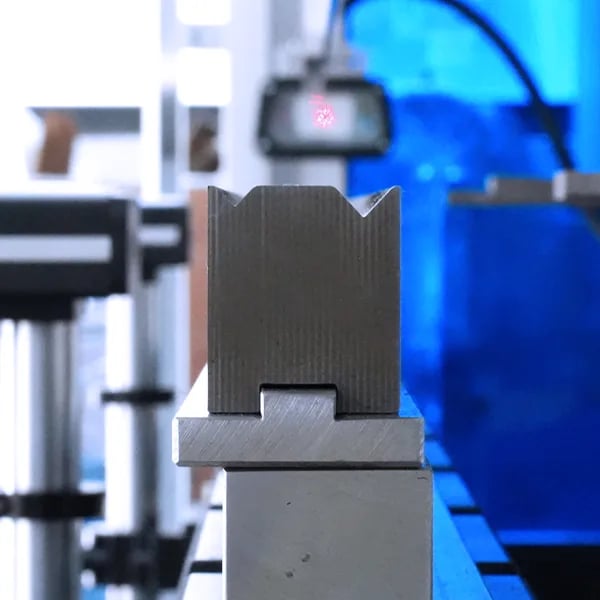

Präzisions-Schnellspannvorrichtung

Es ist praktisch, den oberen Stempel schnell festzuklemmen, die Arbeitsintensität zu reduzieren und die Produktionseffizienz zu verbessern. Das Gebrauchsmuster bietet die Vorteile hoher Präzision, einfacher Klemmung, kein Lösen, kein Herunterfallen des Werkzeugs usw.

CNC-motorisiertes Bombierungssystem

Der niedrige Arbeitstisch verfügt über eine automatische Bombierungskompensationseinheit; der Kompensationsbetrag wird automatisch vom CNC-System eingestellt und garantiert über die gesamte Länge den gleichen Biegewinkel.

Der Arbeitstisch verfügt über ein spezielles Design, das die Wölbungsverzerrung des Unterwerkzeugs wirksam reduziert.

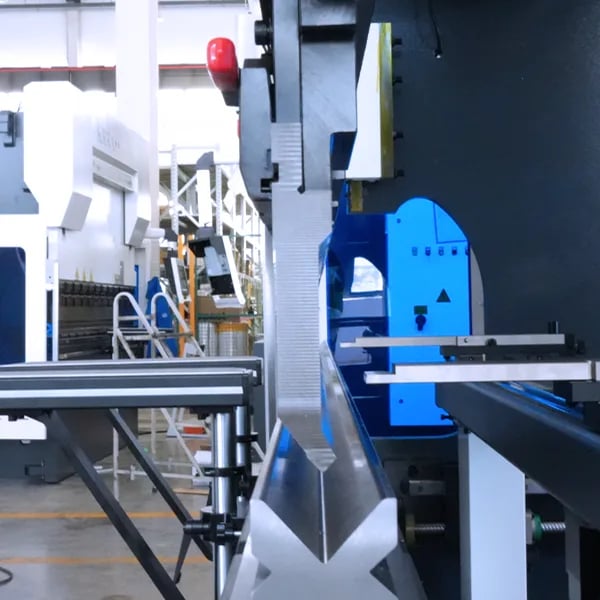

Vordere Materialunterstützung

Die vordere Materialauflage lässt sich frei anheben und absenken. Wenn Sie größere Bleche biegen müssen, kann sie Ihnen effektiv dabei helfen, Ihren Arbeitsaufwand zu reduzieren.

Fußschalter

Der Fußschalter der südkoreanischen Marke ist beweglich gestaltet und ermöglicht mit dem Notschalter einen sofortigen Maschinenstopp. Diese Funktion verbessert die Sicherheit und Betriebskontrolle.

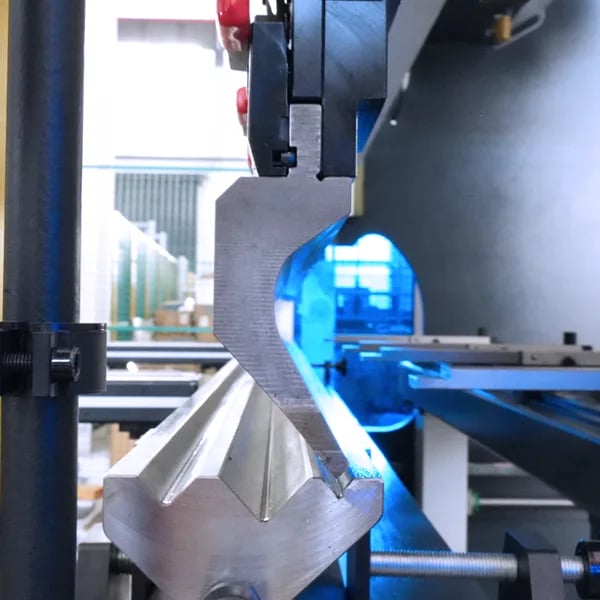

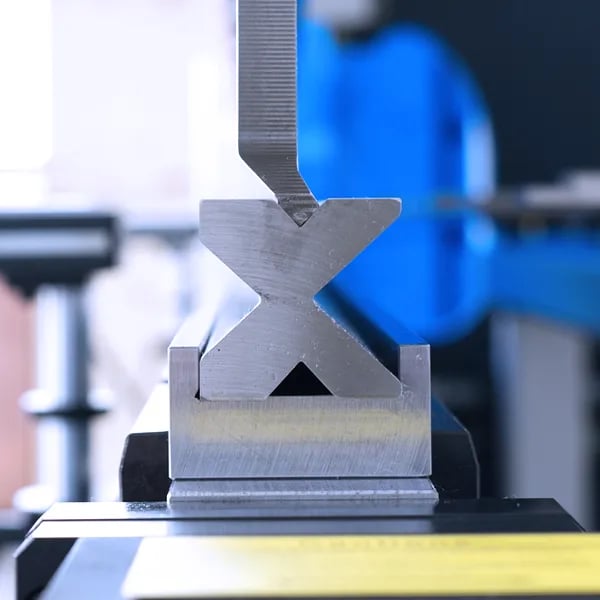

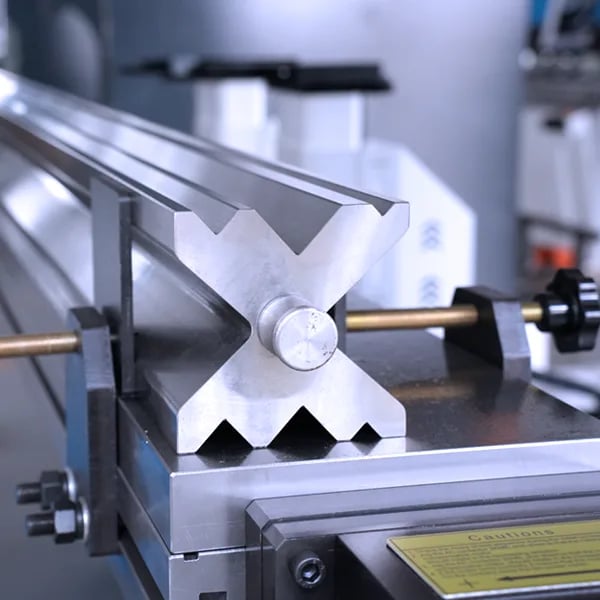

Stempel und Matrizen

Die Stempel und Matrizen für Hybrid-Abkantpressen sind eines der wichtigsten Themen, die wir besprechen, bevor Sie die Bestellung aufgeben. Jede Biegeform wird durch einen geeigneten Satz Stempel und Matrizen vervollständigt. Wir können den Kunden je nach ihren unterschiedlichen Biegeanforderungen geeignete Werkzeuge zur Verfügung stellen.

Industrie 4.0 mit IOT Productivity Monitor™

Dank der fortschrittlichen KRRASS® CNC und der Vernetzung von Ad-hoc-Softwaretools wie der „Smart Factory“ können Unternehmen in die Industrie 4.0 einsteigen, die die Realität von Unternehmen revolutioniert. Sie können Daten extrahieren und Informationen auf Unternehmensebene austauschen: Biegeprogramme, Sensoren, Produktionsstatistiken.

Nachrichten in der Zeit

Ein Balkendiagramm zeigt an, wie viele Meldungen im Laufe der Zeit angezeigt wurden. Es werden nur die Meldungen angezeigt, die aktiv waren, während DA-Control gestartet war. Folgende Meldungskategorien werden angezeigt:

- D = Nachrichten aus der Delem-Anwendung

- M = Nachrichten von einem DM-Modul

- P = Meldungen, die von einer sicheren SPS generiert werden

- S = vom Sequenzer generierte Nachricht

Produkte rechtzeitig

Dieser Block zeigt ein Balkendiagramm an, das für jedes Produkt die pro Tag produzierte Menge angibt. Wenn der Mauszeiger auf einen dieser Balken bewegt wird, werden die Produkt-ID und die Menge für dieses Datum angezeigt.

Leistungsstarker CNC-Controller und Hinteranschlagsystem

Mehrere innovative patentierte Technologien

Eine Vielzahl von Hinteranschlägen ist verfügbar

CNC-Steuerung:

Delem DA-58T Controller

- 2D-grafische Touchscreen-Programmierung

- 15" hochauflösendes Farb-TFT

- Biegefolgeberechnung

- Bombierungskontrolle

- Servo- und Frequenzumrichtersteuerung

- Erweiterte Y-Achsen-Steuerungsalgorithmen für Ventile mit geschlossenem und offenem Regelkreis.

- USB, Peripherieschnittstelle

- Profile-T Offline-Software

Delem DA-66S Controller

- Programmiermodus mit grafischem 2D-Touchscreen

- 3D Maschinendarstellung, in Simulation und Produktion

- 24" hochauflösendes Farb-TFT

- Kompatibilität mit Delem Modusys (Skalierbarkeit und Adaptivität des Moduls)

- USB, Peripherieschnittstelle

- Benutzerspezifische Anwendungsunterstützung innerhalb der Multitasking-Umgebung der Steuerung

- Schnittstelle für Sensorbiegung und -korrektur

- Profile-SL Offline-Software

Delem DA-69S Controller

- 3D- und 2D-Grafik-Touchscreen-Programmiermodus

- 3D-Visualisierung inkl. 3D-Maschinendarstellung in Simulation und Produktion

- 24" hochauflösendes Farb-TFT

- Kompatibilität mit Delem Modusys (Skalierbarkeit und Adaptivität des Moduls)

- USB, Peripherieschnittstelle

- Benutzerspezifische Anwendungsunterstützung innerhalb der Multitasking-Umgebung der Steuerung

- Schnittstelle für Sensorbiegung und -korrektur

- Profile-S3D Offline-Software

Hinteranschlag-Lösung:

3+1 Achsen Hinteranschlag

Die Höhe des Hinteranschlags lässt sich manuell verstellen und erleichtert Ihnen so die Bedienung einiger individueller Zubehörteile beim Einsatz der Blechbiegemaschine.

4+1 Achsen Hinteranschlag

Der hochpräzise Hinteranschlag mit Feineinstellungsfunktion kann dafür sorgen, dass Ihr Biegeprozess effizienter ist und das Werkstück präziser gebogen wird.

4+1+2 Achsen Hinteranschlag

Die elektrischen Achsen Z1 und Z2 werden unabhängig voneinander gesteuert, was die Bedienung komfortabler macht. Verbreiterte und verlängerte benutzerdefinierte Anschlagfinger, Fingerstützrahmen mit doppelter Linearführung, erfüllt Ihre Anforderungen.

6+1 Achsen Hinteranschlag *

Die X-Achse verwendet eine Kugelumlaufspindel und eine Linearführung, um eine hohe Synchronisationsgenauigkeit und eine sehr lange Lebensdauer zu gewährleisten. Verbreiterte und verlängerte benutzerdefinierte Anschlagfinger, Fingerstützrahmen mit doppelter Linearführung, erfüllt Ihre Anforderungen.

7+1 Achsen Hinteranschlag *

Die X-Achse bewegt sich nach vorne und hinten, die R-Achse bewegt sich nach oben und unten, die Z1- und Z2-Achse sind zwei Fingeranschläge, die sich nach links und rechts bewegen, die X1-Achse ist ein Fingeranschlag, der sich nach vorne und hinten bewegt, die 5. Achse wird durch einen CNC-Controller gesteuert, um eine präzise Positionierung der Verbindung zu ermöglichen.

8+1 Achsen Hinteranschlag *

Der Hinteranschlag umfasst eine große Basis mit hoher Steifigkeit sowie einen Antriebsmechanismus für die X-Achse, die R-Achse und den Z-Achsen-Antriebsmechanismus. Je nach Bedarf der zu bearbeitenden Teile kann der Stopperfinger automatisch auf die erforderliche genaue Position eingestellt werden, um die genaue Positionierung des Werkstücks sicherzustellen und so das qualifizierte Werkstück zu bearbeiten.

* Wenn Sie die Hinteranschlagkonfiguration mit 6+1 Achsen, 7+1 Achsen oder 8+1 Achsen wählen, müssen Sie mit einem DA-66S- oder DA-69S-Controller ausgestattet sein.

Andere optionale Konfiguration

Laserschutz

Das aus Italien importierte DSP-Laserschutzgerät kann den Sicherheitsschutz der Hybrid-Abkantpresse umfassend und effektiv gewährleisten und die persönliche Sicherheit des Bedieners schützen.

Laser-Winkelerkennungssystem

Der Einsatz eines Laserwinkelmesssystems kann einen stabilen Biegewinkel des Werkstücks gewährleisten und die Effizienz und Stabilität der automatischen Bearbeitung verbessern.

WlLA Werkzeugklemmen und Halter

Das Oberwerkzeug wird hydraulisch geklemmt und der Klemm- und Lösevorgang wird automatisch elektrisch gesteuert. Die Klemmkraft ist groß und zuverlässig und der Werkzeugwechsel ist einfach und effizient.

Hydraulische Klemmvorrichtung für die untere Matrize. Der Klemm- und Lösevorgang wird automatisch elektrisch gesteuert, wodurch der Matrizenwechsel einfacher und effizienter wird.

CNC-Frontstößelstützen

Wenn das Werkstück gebogen wird, kann die Stützplatte die Drehverfolgungsfunktion realisieren. Der folgende Winkel und die Geschwindigkeit werden automatisch vom NC-System berechnet und gesteuert und können sich entlang der linearen Führungsschiene nach links und rechts bewegen.

WILA Werkzeugaufbewahrungssystem

Um diesen Bedarf an kundenspezifischen Hybrid-Abkantpressen zu decken, bietet Krrass innovative Werkzeugaufbewahrungslösungen speziell für Standard- und kundenspezifische Werkzeuge für Hybrid-Abkantpressen: die Tool Station (modulares Werkzeugaufbewahrungs- und -wechselsystem) und Standard-Werkzeugschränke.

Biegeflexible Verarbeitungseinheit

Bieten Sie entsprechend Ihren Produktions- und Verarbeitungsanforderungen flexible Automatisierungslösungen für Blech.

Werkzeuge (optional)

Kontaktieren Sie uns

Bei Fragen kontaktieren Sie uns bitte, wir werden uns schnellstmöglich bei Ihnen melden.

Telefon

+86 189 5208 7956

Standort

Nanjing, Jiangsu, China