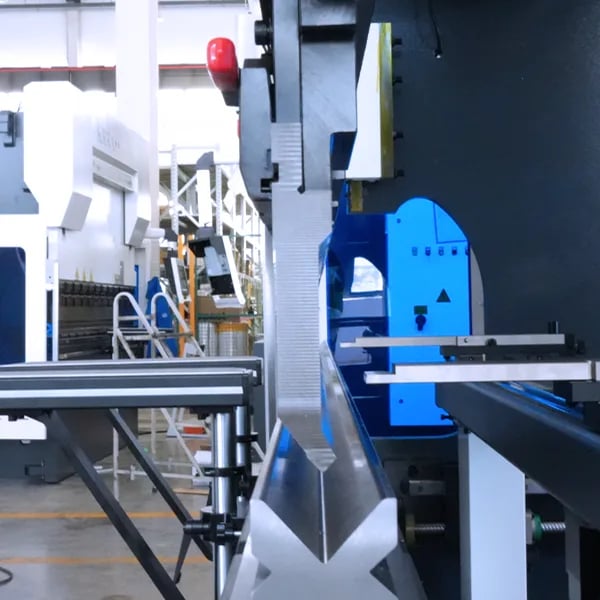

Electric Press Brake Machine - EPP Series

The EPP Series Electric Press Brake from KRRASS features the advantages of fast acceleration and deceleration, and rapid response time of the ball screw servo drive system. Plus, it eliminates the need for hydraulic oil and reduces energy consumption by 50%.

Electric Press Brake Machine - EPP Series

Features & Configuration

Main Features

Imported configuration, stable and reliable

High strength frame with thick plate and sufficient material High precision rear retaining system

Standard 4+1 Axis (X, Y1, Y2, R+W)

Closed loop control and worktable auto mechanical deflection compensation

Universal High-End Intelligent Electric Press Brake

The EPP range offers high versatility and has a large number of optional accessories and equipment

Standard Configuration

Delem DA-53T Controller

- "Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

C-type Throat Deformation Compensation Device

Fagor grating ruler can accurately measure the small deformation caused by bending force of machine tool,then feedback compensation, to ensure the bending accuracy of plates of any thickness and materia.

Schneider Electric

High-quality electrical components can perform well even when the electricity supply is unstable, and customers can easily obtain replacements anywhere in the world.

X-axis Servo Motor

In addition, the advantages of servo motors include:

- High reliability: Highly reliable

- High ratio of torque to inertia: Can provide as much as 50% more torque in many applications

- High precision: Can precisely actuate, hold, and speed up positions, torque, and speeds in fractions of seconds

R-axis Servo Motor

Servo motors have several advantages, including:

- High efficiency: Can approach 90% at light loads

- High output power: Relative to their size and weight

- Closed-loop control: Ensures greater accuracy

- Quiet operation: Little sound noise

Energy saving advantages

- High dynamic for a higher productivity of the machine.

- Compliance with EU Directives.

- Lower energy for a green Machine.

- Lowered sound pressure level at 50 dB.

- The servo-motor, with closed loop speed control.

- Energy efficiency of up to 35 % compared to conventional systems.

- Operating cost is min due to low energy consumption. Thus, it gives advantages to the user with high efficiency & low operation cost.

X-axis Ball Screw Linear Guide

- Precision: Ball screws offer enhanced precision, reduced energy consumption, and lower maintenance requirements.

- Responsiveness: Ball screws deliver exceptionally smooth motion.

- Friction: Ball screws rely on recirculating balls to reduce friction instead of lubricants.

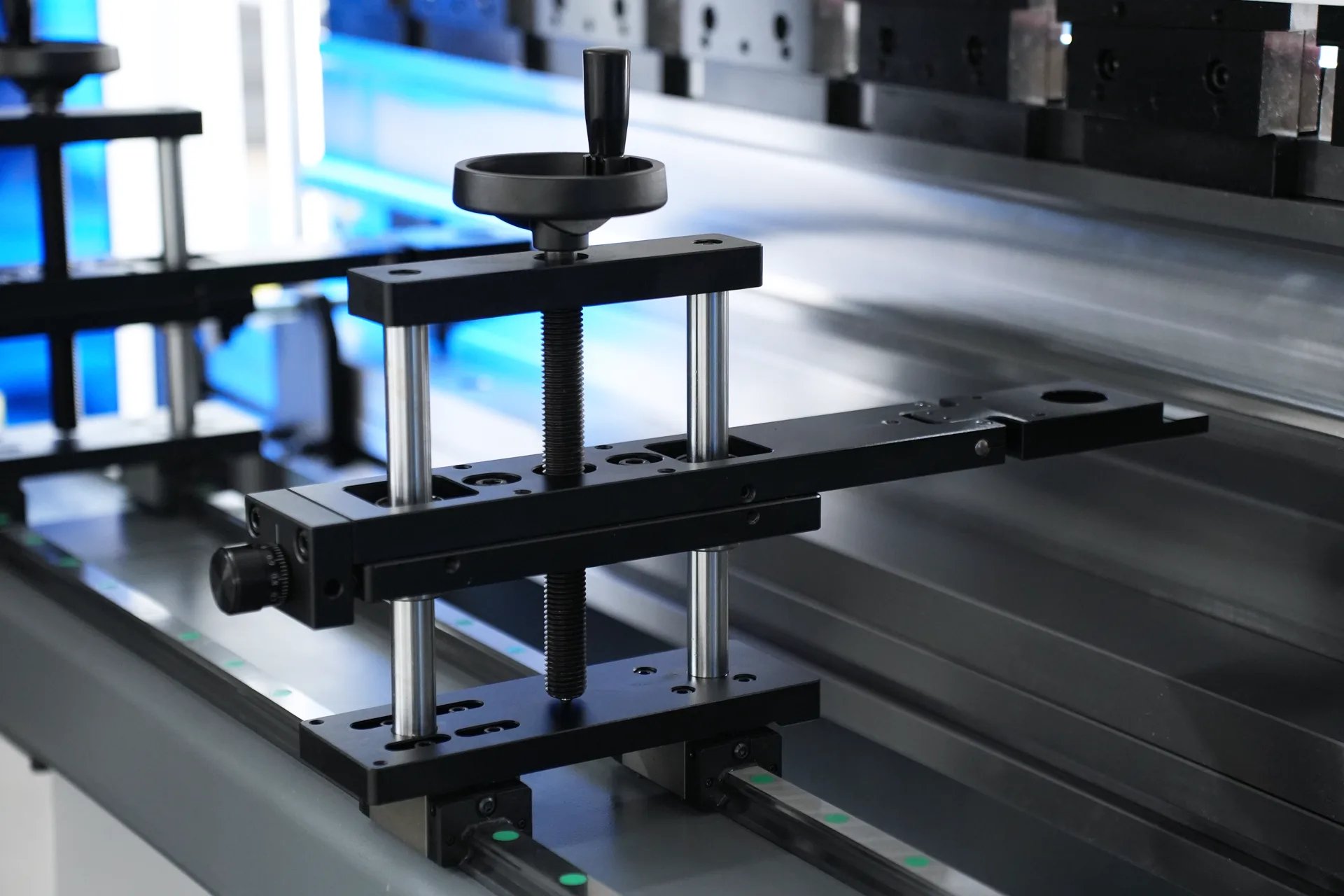

Back Finger Stoper

High-precision backstop means that customers can input the size into the system according to the product’s dimensions, and it can be positioned accurately with an accuracy of 0.01mm.

The crossbeam is designed with double linear guide rails, allowing the blocking fingers to move both left and right along them.

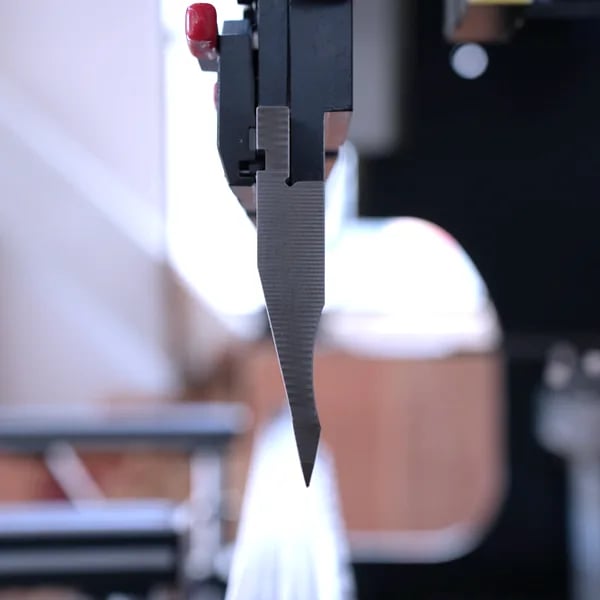

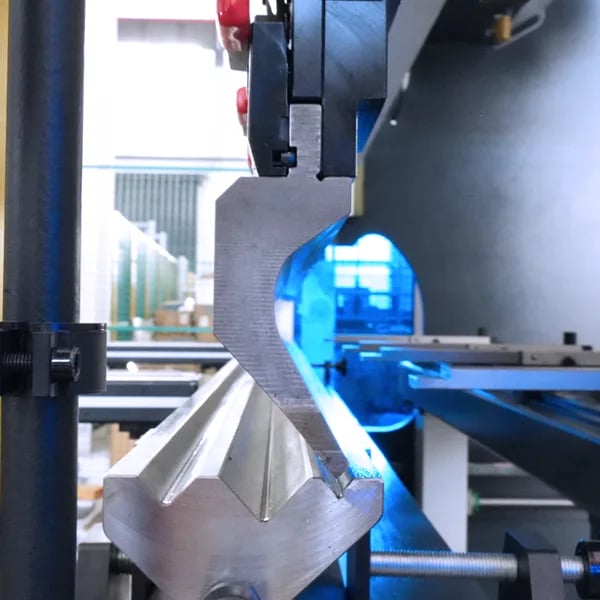

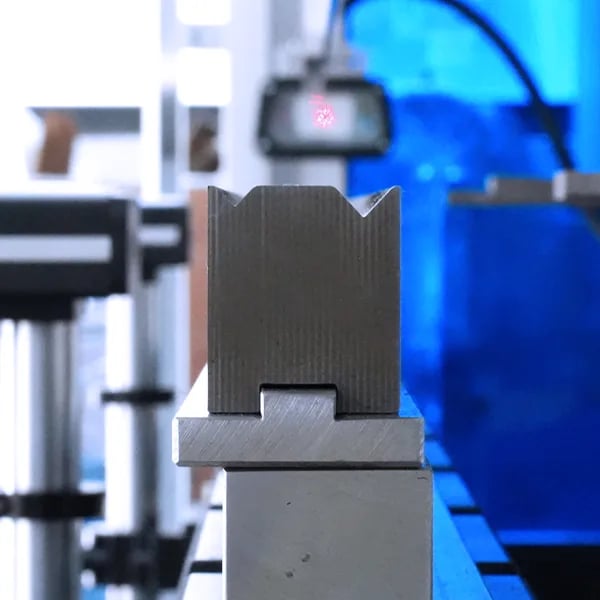

Precision Quick Clamping Device

It is convenient to quickly clamp the upper die, reduce labor intensity and improve production efficiency. The utility model has the advantages of high precision, easy clamping, no loosening, no tool dropping, etc.

CNC Motorized Crowning System

Low worktable has an automatic crowning compensation uint; compensation amount is automatically set up by CNC system, with guarantee a same bending angel on full length.

The worktable adopts the particular design, reducing the crowning distortion amount of lower tool effectively.

Front Material Support

The front material support can be lifted and lowered freely. When you need to bend larger metal sheets, it can effectively assist in reducing your workload.

Pedal Switch

The South Korean brand foot switch is designed to be movable, allowing for immediate machine stoppage with the emergency button. This feature enhances safety and operational control.

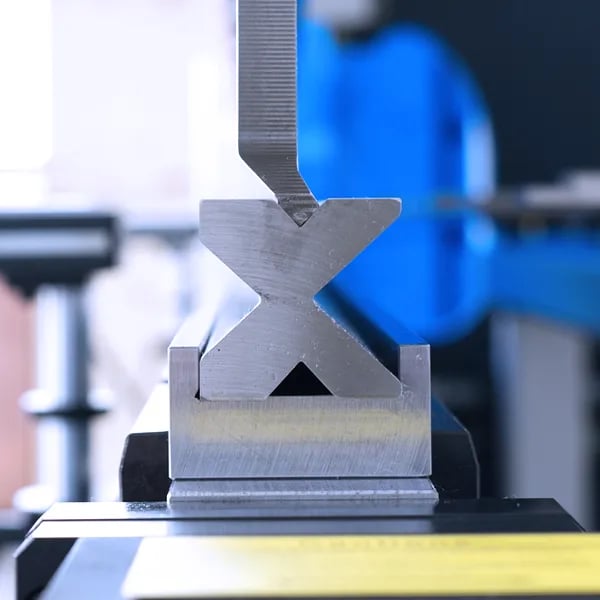

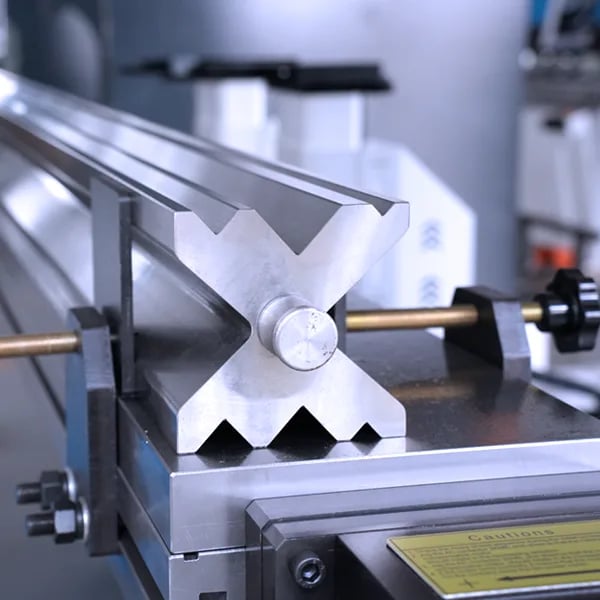

Punches & Dies

Electric Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate tooling according to different bending requirements of customers.

Offline Software

The Profile-T3D software makes possible the offline programming and simulation of the bending process. It is software on any remote computer and it maximizes the efficiency and production output of the Electric Press Brake.

Industry 4.0 With IOT Productivity Monitor™

Thanks to the advanced KRRASS® CNC and interconnecting ad-hoc software tools like the “Smart Factory” make it possible for companies to enter industry 4.0 that is revolutionizing the reality of companies.you can extract data and share information at company level: bending programs, sensors, production statistics.

Powerful CNC Controller and Back Gauge System

Several innovative patented technologies

A variety of back gauge are available

CNC Controller:

Delem DA-58T Controller

- 2D graphical touch screen programming

- 15" high resolution color TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

Delem DA-66S Controller

- 2D graphical touch screen programming mode

- 3D machine representation, in simulation and production

- 24" high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-SL offline software

Delem DA-69S Controller

- 3D and 2D graphical touch screen programming mode

- 3D visualization, including 3D machine representation, in simulation and production

- 24" high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-S3D offline software

Backgauge solution:

3+1 Axis Back Gauge

The height of the backgauge can be adjusted manually, making it easier for you to operate some customized accessories when using the sheet metal bending machine.

4+1 Axis Back Gauge

The high-precision backgauge with fine-tuning function can ensure that your bending process is more efficient and the workpiece is bent more accurately.

4+1+2 Axis Back Gauge

Electric Z1, Z2-axis is independently controlled, making operation more convenient. Widened and extended custom stop fingers, Finger support frame with double linear guide, Meet your reguirements.

6+1 Axis Back Gauge *

X axis adopts ball screw and linear quide, ensure high synchronization accuracy and very long life. Widened and extended custom stop fingers, Finger support frame with double linear guide, Meet your reguirements.

7+1 Axis Back Gauge *

X axis move front and rear, R axis move upward and downward, Z1 axis and Z2 axis are two finger stops move left and right, X1 axis is finger stop moving front and rear, 5 axis controlled by CNc controller to make linkage positioning precisely.

8+1 Axis Back Gauge *

The back gauge includes high rigidity big base, X-axis drive mechanism, R-axis drive mechanism and z-axis drive mechanism; according to the needs of processing parts, the stopper finger can be automatically adjusted to the required accurate position to ensure the accurate positioning of the workpiece, so as to process the qualified workpiece.

* If you choose the 6+1 axis, 7+1 axis, or 8+1 axis backgauge configuration, you must be equipped with a DA-66S or DA-69S controller.

Other Optional Configuration

Laser Protection

The DSP laser protection device imported from ltaly can comprehensively and effectively provide the safety protection of the electric press brake and protect the personal safety of the operator.

Laser Angle Detection System

The use of laser angle measurement system can ensure a stable workpiece bending angle and improve the efficiency and stability of automatic machining.

WlLA Tool Clamping and Holders

The upper die is hydraulically clamped, and the clamping and loosening action is automatically controlled by electricity. The clamping force is large and reliable, and the die change is easy and efficient.

Lower die hydraulic clamping device, clamping and loosening action is automatically controlled by electricity, and die change is easier and more efficient.

CNC Front Follower Supports

When the workpiece is bent, the support plate can realize the turning following function. The following angle and speed are automatically calculated and controlled by the Nc system, and can move left and right along the linear guide rail.

WILA Tool Storage System

To answer these custom electric press brakes needs, Krrass provides innovative tool storage solutions dedicated to electric press brake standard & custom tooling : the Tool Station (modular tooling storage & changing system) and standard tooling cabinets.

Bending Flexible Processing Unit

According to your production and processing needs,provide flexible automation solutions for sheet metal.

Tooling (Optional)

Get in touch

If you have any questions, please contact us, we will get back to you as soon as possible.

Phone

+86 189 5208 7956

Location

Nanjing, Jiangsu, China