Prensa plegadora hidráulica WC67K con controlador E21

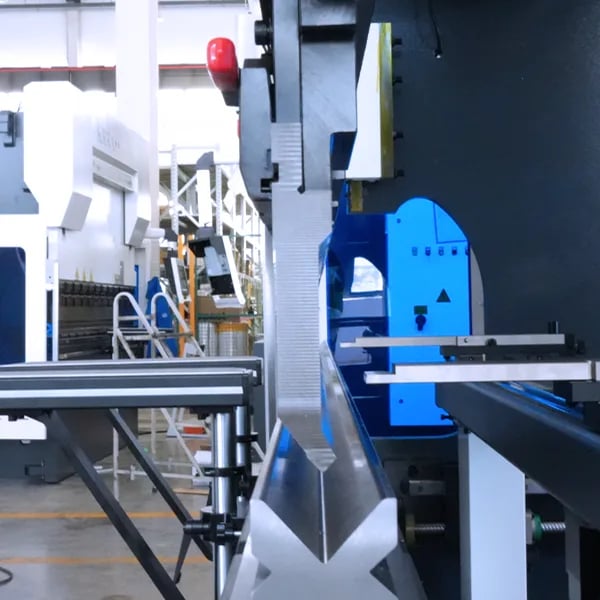

La prensa plegadora hidráulica con controlador E21, que cuenta con una unidad de control fácil de usar, un bastidor rígido, un diseño impecable, alta eficiencia, soluciones para el uso de múltiples herramientas, los más altos estándares de seguridad CE y un rango de precios adecuado, se considera la mejor del mundo. Es ideal para soluciones sensibles a las curvas y de bajo consumo energético.

Prensa plegadora hidráulica WC67K (controlador E21)

Características y configuración

Características principales

La configuración importada es estable y confiable.

Bastidor de alta resistencia con placas gruesas y materiales suficientes. Sistema de retención trasera de alta precisión.

El área de trabajo se puede personalizar y se pueden instalar todo tipo de sujeción de herramientas.

Prensa plegadora hidráulica a medida.

Inteligente universal de alta gama Prensa plegadora hidráulica

La gama WC67K ofrece una gran versatilidad e incluye una gran cantidad de accesorios y equipos opcionales.

Configuración estándar

Controlador ESTUN E21

- Control del tope trasero

- Controlar el motor común o inversor

- Posicionamiento inteligente de ejes X e Y

- Programación de varios pasos, 40 programas, cada programa de 25 pasos

- Función de relé de tiempo incorporado

- Cambio de función con un solo botón

- Función de posicionamiento unilateral

- Una copia de seguridad y restauración de parámetros clave

Interruptor de límite de carrera del eje Y

El interruptor de límite de carrera del eje Y de respuesta rápida y alta precisión puede proporcionar información rápida y precisa sobre los datos de carrera del eje Y al controlador, mejorando así la eficiencia de producción de su pieza de trabajo.

Además, el aumento de los ciclos operativos también se traduce en una vida útil más larga, lo que garantiza que su prensa plegadora hidráulica funcione con mayor suavidad.

Schneider Electric

Los componentes eléctricos de alta calidad pueden funcionar bien incluso cuando el suministro eléctrico es inestable y los clientes pueden obtener reemplazos fácilmente en cualquier parte del mundo.

Motor reductor de 400 W para eje Y

Los motores reductores tienen varias ventajas, entre ellas:

- Aumento del par de salida

- Reducción de la velocidad de entrada para aplicaciones específicas

- Mejora de la eficiencia del sistema mecánico

- Permitiendo un control preciso de la velocidad

- Adaptación de fuentes de energía a diversas maquinarias

- Reducción del desgaste de los componentes

- Mejorar el rendimiento en diversas industrias

Motor reductor de 200 W para eje X

El motor del eje X de la prensa plegadora ofrece un control preciso, alta velocidad, durabilidad, versatilidad en el posicionamiento de la herramienta y una integración perfecta con los sistemas de automatización para un mejor rendimiento.

PRIMERAS válvulas hidráulicas

El grupo de válvulas de USA FIRST se utiliza para garantizar una mayor precisión de curvatura y una vida útil más larga.

Las tuberías hidráulicas están fabricadas por la marca alemana EMB, que garantiza que nunca habrá fugas de aceite.

Motor principal Siemens alemán

El reconocido y prestigioso motor de la marca alemana no solo extiende la vida útil operativa de la máquina, sino que también mantiene su funcionamiento eficiente en un entorno sereno con niveles de ruido reducidos, mejorando así la productividad general y la experiencia del usuario.

PRIMERA bomba de aceite hidráulica

La bomba de aceite American FIRST es muy valorada por su rendimiento excepcional, conocida por su funcionamiento silencioso y su notable longevidad, lo que la convierte en una opción confiable para diversas aplicaciones.

Guía lineal de husillo de bolas en el eje X

- Precisión: Los tornillos de bolas ofrecen una precisión mejorada, un menor consumo de energía y menores requisitos de mantenimiento.

- Capacidad de respuesta: Los tornillos de bolas proporcionan un movimiento excepcionalmente suave.

- Fricción: Los tornillos de bolas se basan en bolas recirculantes para reducir la fricción en lugar de lubricantes.

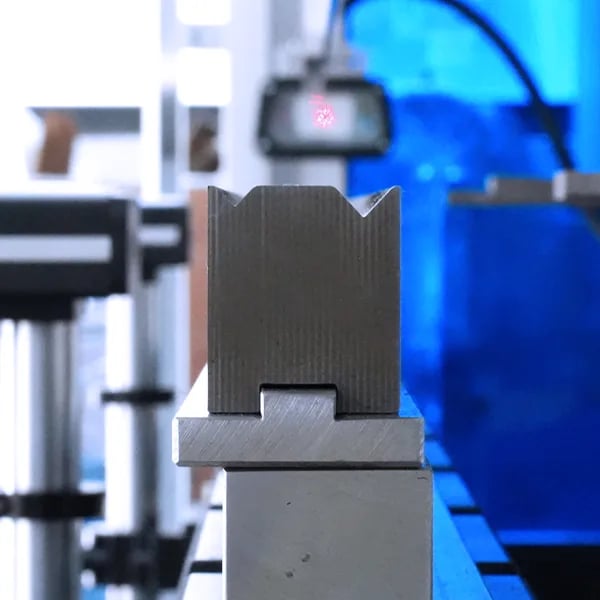

Tope de dedo trasero de ajuste fino de alta precisión

El tope trasero de alta precisión significa que los clientes pueden ingresar el tamaño en el sistema de acuerdo con las dimensiones del producto, y se puede posicionar con precisión con una exactitud de 0,01 mm.

La viga transversal está diseñada con rieles de guía lineales dobles, lo que permite que los dedos de bloqueo se muevan tanto hacia la izquierda como hacia la derecha a lo largo de ellos.

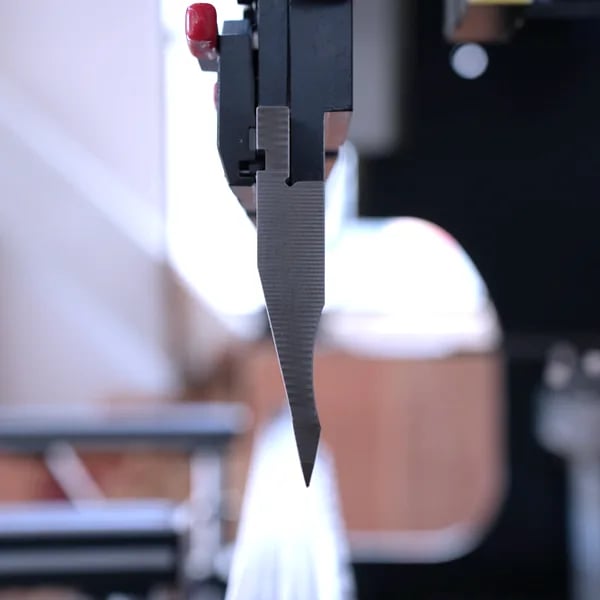

Sujeción manual de la herramienta superior

Nuestras prensas plegadoras utilizan materias primas suministradas por proveedores calificados y la composición química corresponde a los estándares internacionales. Por lo tanto, el rendimiento de la materia prima y la resistencia a la tracción están garantizados. Los materiales están estandarizados con una ranura de seguridad de 8,4 x 3,5 mm, que evita que la herramienta se caiga.

Soporte de material frontal

El soporte de material delantero se puede levantar y bajar libremente. Cuando necesite doblar láminas de metal más grandes, puede ayudar de manera efectiva a reducir su carga de trabajo.

Interruptor de pedal

El pedal de la marca surcoreana está diseñado para ser móvil, lo que permite detener inmediatamente la máquina con el botón de emergencia. Esta característica mejora la seguridad y el control operativo.

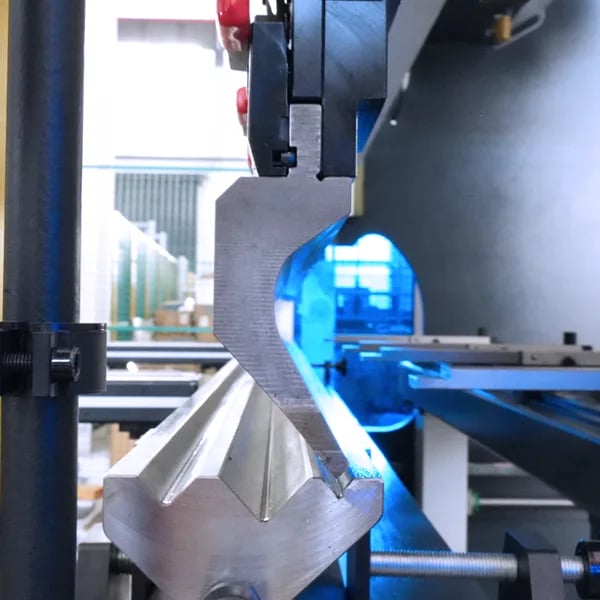

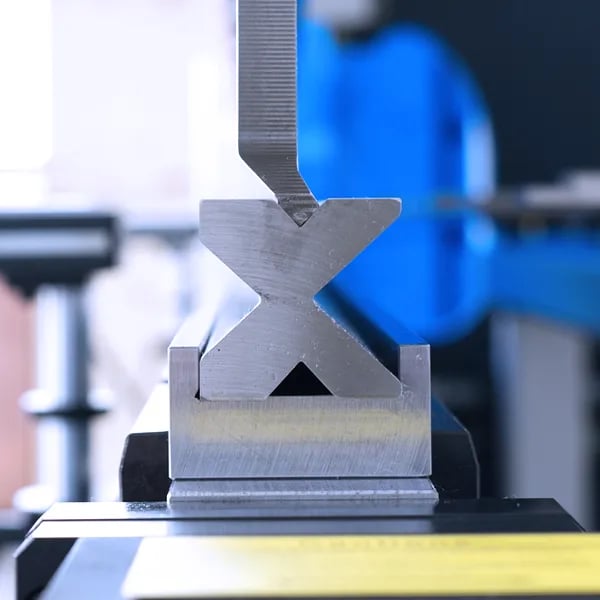

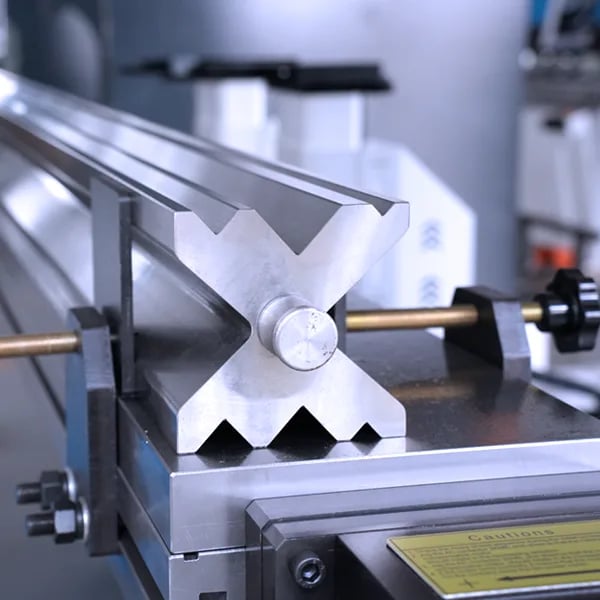

Punzones y matrices

Los punzones y matrices para prensas plegadoras hidráulicas serán uno de los temas más importantes que trataremos antes de que realice el pedido. Cualquier forma de plegado se completará con un juego adecuado de punzones y matrices. Podemos proporcionar las herramientas adecuadas según los diferentes requisitos de plegado de los clientes.

Configuración opcional

Controlador de posición ELGO P40

- Versión de uno o dos ejes

- Pantalla LCD

- Fácil manejo

- Navegación por menú en varios idiomas

- Opción salida analógica PID disponible

- Ejecución de referencia

- Modo manual, individual y de programa

Sistema de coronación manual

La deformación elástica que se produce en el centro del carro de la plegadora NC y en el centro de la mesa de trabajo provoca inconsistencias en el ángulo a lo largo de toda su longitud durante el plegado, lo que es un factor importante que afecta la precisión del plegado. Por ello, nuestra plegadora 300T viene equipada con esta función de serie.

Sistema de protección de seguridad fotoeléctrico

Toda la máquina está equipada con sistemas de protección de seguridad fotoeléctrica en la parte delantera y trasera para garantizar una producción eficiente y la seguridad personal de los operadores.

Protección punto a punto en la espalda

Cuando la prensa plegadora hidráulica está en funcionamiento, la protección punto a punto en la parte posterior puede responder rápidamente a cualquier entrada de contacto anormal. Si alguien ingresa por error al área de trabajo en la parte trasera de la prensa plegadora, detendrá inmediatamente la máquina dobladora para garantizar la seguridad de las personas y la propiedad.

Herramientas (opcional)

Ponte en contacto con nosotros

Si tiene alguna pregunta, comuníquese con nosotros y nos comunicaremos con usted lo antes posible.

Correo electrónico

Teléfono

+86 189 5208 7956

Ubicación

Nanjing, Jiangsu, China