Cizalla hidráulica de viga oscilante

Las cizallas hidráulicas de viga oscilante adoptan estándares de alta tecnología, diseño y una interfaz fácil de usar. Hemos reducido el ángulo de corte para lograr precisión recta y una tolerancia de torsión mínima. La cizalla hidráulica QC12K brinda perfección con soluciones eficientes y de seguridad de alto estándar que fortalecen sus habilidades y agregan valor a su empresa.

Cizalla hidráulica con viga oscilante (serie QC12K)

Características y configuración

Características principales

Configuración importada, estable y confiable.

Bastidor de alta resistencia con placa gruesa y material suficiente Sistema de retención trasera de alta precisión

El espesor máximo de corte puede alcanzar los 30 mm.

Ancho máximo de trabajo hasta 8 metros

Inteligente universal de alta gama Cizalla de viga oscilante

¿Qué es la cizalla de viga oscilante?

La cuchilla superior penetra la chapa por encima del borde inferior. Un movimiento pivotante corta la viga oscilante. Una vez realizada la cantidad, la cuchilla superior se aleja de la cuchilla inferior. La cuchilla superior se aleja del borde inferior después del corte. La cuchilla superior e inferior no se frotan entre sí. Un movimiento pivotante corta la viga oscilante. Una vez realizada la cantidad, el borde superior se aleja de la cuchilla inferior. La holgura de la cuchilla se puede ajustar fácilmente girando la excéntrica de separación de corte. El borde superior se aleja de la cuchilla inferior después del corte. La cuchilla superior e inferior no se frotan entre sí. El corte con viga oscilante requiere un diseño de cizalla montada. La razón es el ángulo de inclinación bajo, que es la solución para cualquier espesor de material.

Controlador CNC

¡Personalice el controlador para liberar todo el potencial de su máquina cizalla con viga oscilante serie KRRASS QC12K!

Mando ESTUN E21S

- Pantalla hidráulica de alta definición

- Controlar motores comunes y convertidores de frecuencia

- Posicionamiento inteligente del eje X

- Programación de varios pasos, 40 programas, cada programa de 25 pasos

- Función de relé de tiempo incorporado

- Cambio de función con un solo botón

- Función de posicionamiento unilateral

- Una copia de seguridad y restauración de parámetros clave

- Chino e inglés

- Sistema métrico

Configuración estándar

Análisis de tensiones y análisis de elementos finitos

El software CAE SOLIDWORKS se utiliza como método para analizar la construcción estática lineal, la tensión y la deformación de los marcos de las máquinas de corte por láser y de plegado de prensas. Por lo tanto, para estructuras complicadas, cargas muy complejas, modelado transitorio y una combinación de los anteriores, el método FEA tiene sentido.

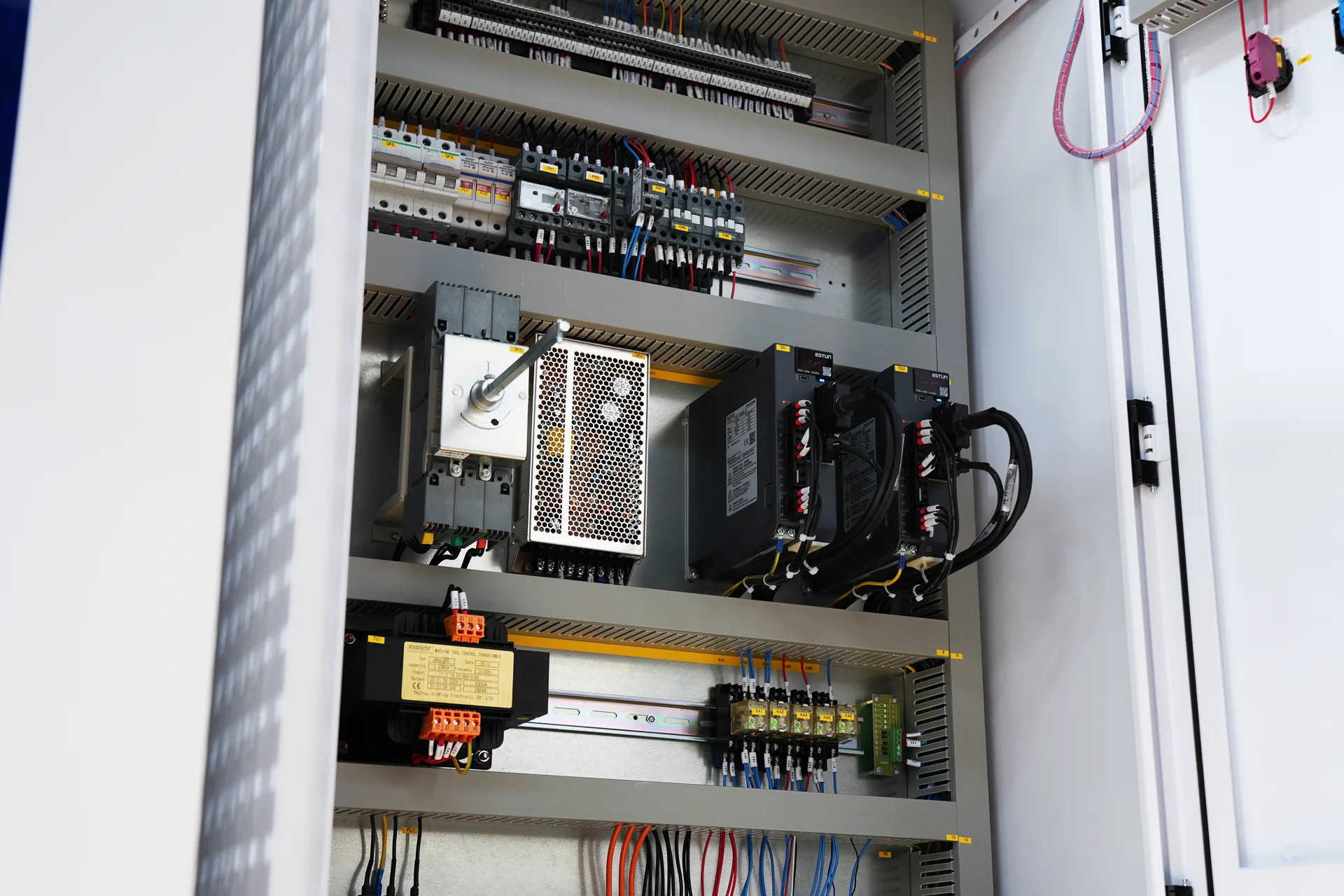

Schneider Electric

Las piezas eléctricas de alta calidad pueden funcionar bien incluso si la electricidad no es estable y los clientes pueden obtener el reemplazo fácilmente en cualquier parte del mundo.

Motor y tornillo del eje X

La holgura del tope trasero del eje X está controlada por E21s, lo que garantiza una mayor precisión de corte. Tope trasero con tornillo de bola opcional y riel guía de línea.

Ajuste de la holgura de la cuchilla

¡Ajuste la distancia de las cuchillas de corte con la moto! De acuerdo con el espesor de corte de la hoja de metal se puede obtener un mejor rendimiento de corte.

PRIMERA válvula hidráulica

La marca mundialmente famosa FIRST, es un proveedor profesional de válvulas hidráulicas.

La junta de la tubería de aceite EMB tiene una hermosa estructura y reduce la posibilidad de fugas de aceite.

Motor principal Siemens alemán

El motor de la famosa marca alemana aumenta la vida útil de la máquina y la mantiene funcionando en un entorno con poco ruido.

PRIMERA bomba de aceite hidráulica

La bomba de aceite es muy valorada por su rendimiento excepcional, conocida por su funcionamiento silencioso y su notable longevidad, lo que la convierte en una opción confiable para diversas aplicaciones.

Soporte de material frontal

El estante de material frontal puede ayudarlo a reducir eficazmente la presión de trabajo cuando está cortando láminas de metal más grandes, lo que le permite sostener y mover las láminas con mayor facilidad.

Interruptor de pedal

El interruptor de pie de la marca de Corea del Sur es movible y puede detener la máquina en cualquier momento mediante el botón de emergencia.

Potente sistema controlador CNC

Varias tecnologías patentadas innovadoras

Hay una variedad de controladores disponibles

Control de eliminación del DAC-362T

- Vivienda basada en paneles

- Pantalla LCD brillante

- Control de calibre delantero/trasero

- Función de retracción

- Control del ángulo de corte y de la distancia entre ejes

- Limitación de la longitud del trazo

- Movimiento manual de todos los ejes

- Control de fuerza

- Medición del espesor de chapa

- Función de devolución al remitente

- Segundo y tercer eje servo (DAC-362T)

- Soporte de hoja

Mando ELGO P40

- Versión de uno o dos ejes

- Pantalla LCD

- Fácil manejo

- Navegación por menú en varios idiomas

- Opción salida analógica PID disponible

- Ejecución de referencia

- Modo manual, individual y de programa

Otra configuración opcional

Soporte lumbar neumático

La posición de almacenamiento de los productos de placa terminados se ajusta mediante un dispositivo neumático para mejorar la eficiencia del trabajo.

Protección de seguridad fotoeléctrica

El sistema de protección de respuesta rápida puede proteger eficazmente la seguridad de los operadores del equipo y evitar lesiones accidentales.

Preguntas frecuentes

¿Qué es una cizalla de viga oscilante?

Las tijeras son Máquinas herramienta utilizadas para cortes rectos en chapa metálica.En una cizalla de viga oscilante, la viga oscilante se mueve con la cuchilla superior en un arco circular. En una cizalla guittina, la viga superior se mueve en línea recta hacia abajo.

¿Cuál es la diferencia entre una cizalla y una guillotina?

La primera es una cizalla de viga oscilante, que se mueve con la cuchilla superior en un arco circular. La segunda es una guillotina de chapa, donde la viga superior se mueve hacia arriba y hacia abajo en línea recta..

Ponte en contacto con nosotros

Si tiene alguna pregunta, comuníquese con nosotros y nos comunicaremos con usted lo antes posible.

Correo electrónico

Teléfono

+86 189 5208 7956

Ubicación

Nanjing, Jiangsu, China