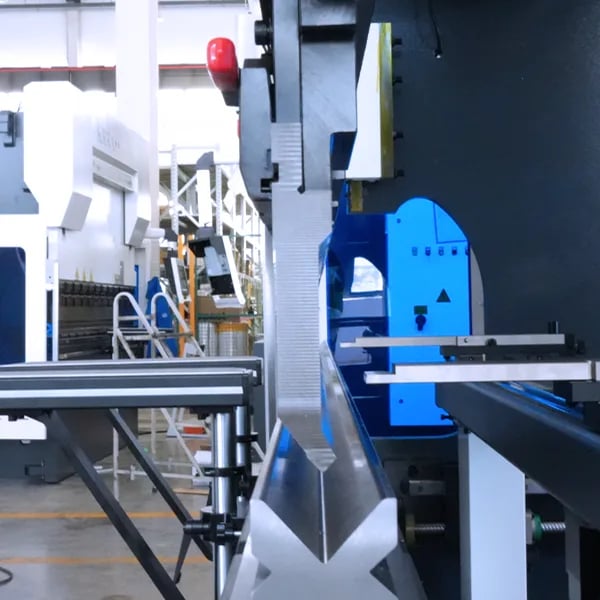

WC67K Hydraulic Press Brake with E21 Controller

The Hydraulic Press Brake with an E21 Controller, featuring an easy-to-use control unit, rigid body frame, flawless design, high efficiency, multiple tool usage solutions, top CE safety standards, and a suitable price range, is considered the best-in-class world leader. It is ideal for bend-sensitive and energy-efficient solutions.

WC67K Hydraulic Press Brake(E21 Controller)

Features & Configuration

Main Features

The imported configuration is stable and reliable.

High-strength frame with thick plates and sufficient materials. High-precision rear retaining system.

The work area can be customized, and all types of tool clamping can be installed.

Tailor-made Hydraulic Press Brake.

Universal High-End Intelligent Hydraulic Press Brake Machine

The WC67K range offers high versatility and includes a large number of optional accessories and equipment.

Standard Configuration

ESTUN E21 Controller

- Backgauge control

- Control the common motor or inverter

- X&Y-axis intelligent positioning

- Multi-step programming, 40 programs, each program 25 steps

- Built-in time relay function

- One-button function switching

- Unilateral positioning function

- A key backup and restore of parameters

Y-axis Stroke Limit Switch

The high-precision, fast-response Y-axis stroke limit switch can quickly and accurately provide feedback on Y-axis stroke data to the controller, enhancing your workpiece production efficiency.

Furthermore, increased operational cycles also result in a longer service life, ensuring that your hydraulic press brake runs more smoothly.

Schneider Electric

High-quality electrical components can perform well even when the electricity supply is unstable, and customers can easily obtain replacements anywhere in the world.

Y-axis 400W Reduction Motor

Reduction motors have several advantages, including:

- Increasing output torque

- Lowering input speed for specific applications

- Enhancing mechanical system efficiency

- Allowing for precise speed control

- Adapting power sources to various machinery

- Reducing wear and tear on components

- Improving performance in diverse industries

X-axis 200W Reduction Motor

The X-axis motor of the press brake offers precise control, high speed, durability, versatility in tool positioning, and seamless integration with automation systems for enhanced performance.

FIRST Hydraulic Valves

The valve group from USA FIRST is used to ensure greater bending accuracy and longer service life.

The hydraulic pipes are made by the German brand EMB, which is guaranteed to never leak oil.

German Siemens Main Motor

The reputable and highly acclaimed German brand motor not only extends the operational lifespan of the machine but also maintains its efficient functioning in a serene environment with reduced noise levels, thereby enhancing overall productivity and user experience.

FIRST Hydraulic Oil Pump

The American FIRST oil pump is highly regarded for its exceptional performance, known for its quiet operation and remarkable longevity, making it a reliable choice for various applications.

X-axis Ball Screw Linear Guide

- Precision: Ball screws offer enhanced precision, reduced energy consumption, and lower maintenance requirements.

- Responsiveness: Ball screws deliver exceptionally smooth motion.

- Friction: Ball screws rely on recirculating balls to reduce friction instead of lubricants.

Hight-Precision Fine-tuning Back Finger Stoper

High-precision backstop means that customers can input the size into the system according to the product's dimensions, and it can be positioned accurately with an accuracy of 0.01mm.

The crossbeam is designed with double linear guide rails, allowing the blocking fingers to move both left and right along them.

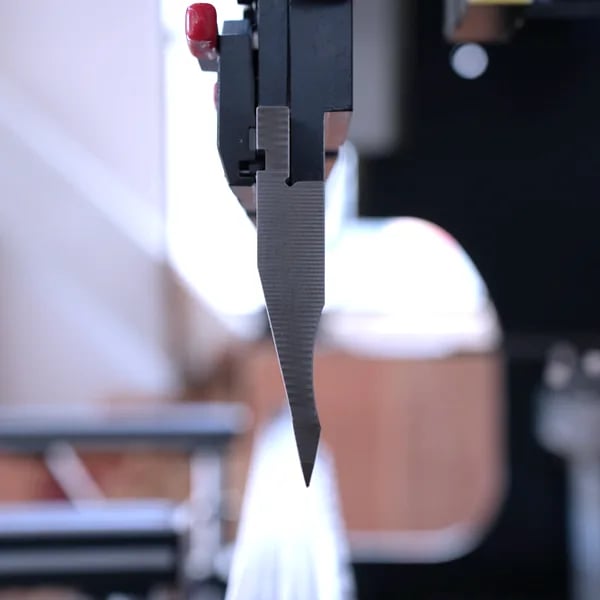

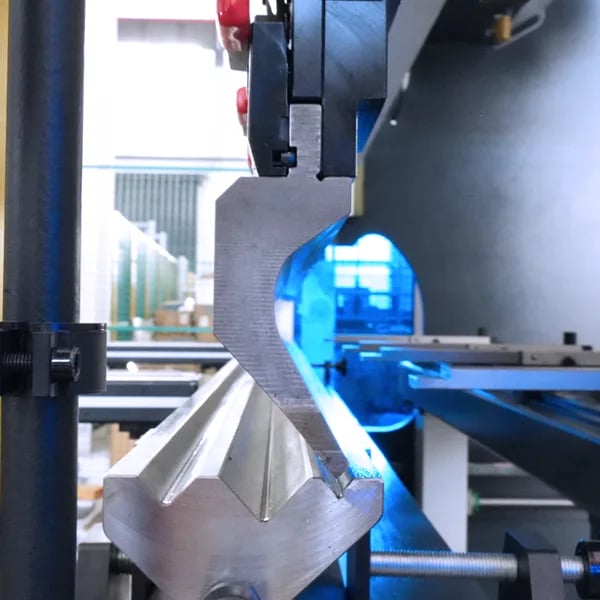

Manual Upper Tool Clamping

Our press brake uses raw material provided by qualified suppliers, and the chemical composition corresponds to international standards. Therefore, the raw material yield and tensile strength are guaranteed. The materials are standardized with an 8.4 x 3.5 mm safety groove, which prevents the tool from falling out.

Front Material Support

The front material support can be lifted and lowered freely. When you need to bend larger metal sheets, it can effectively assist in reducing your workload.

Pedal Switch

The South Korean brand foot switch is designed to be movable, allowing for immediate machine stoppage with the emergency button. This feature enhances safety and operational control.

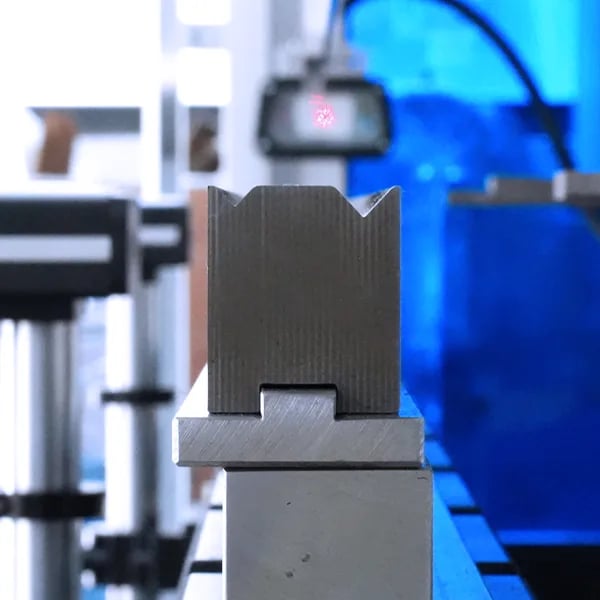

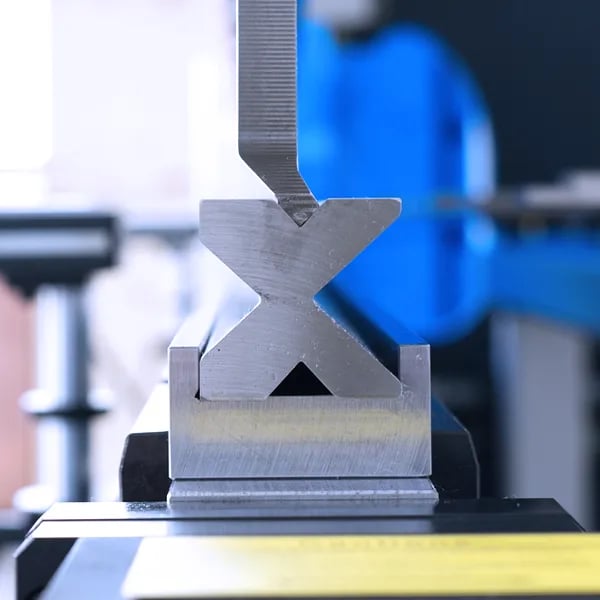

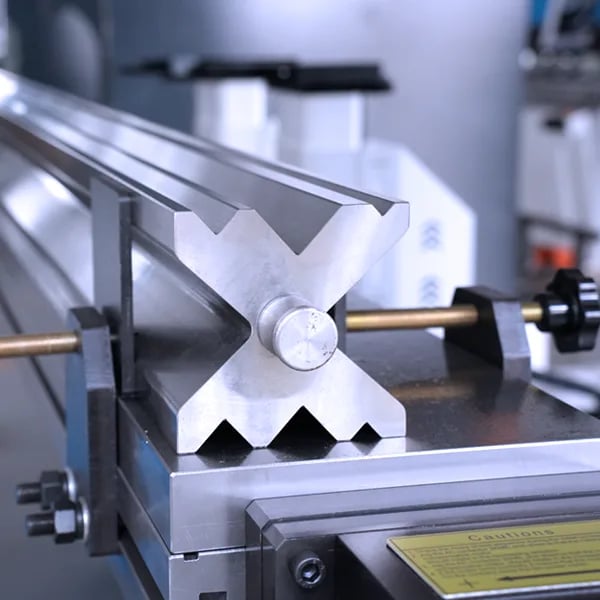

Punches & Dies

Hydraulic Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate tooling according to different bending requirements of customers.

Optional Configuration

ELGO P40 Position Controller

- One- or two-axis version

- LCD display

- Easy handling

- Multi-lingual menu navigation

- Option PID analog output available

- Reference run

- Manual-, single- and program mode

Manual Crowning System

The elastic deformation produced in the middle of the slider of the NC press brake and in the middle of the worktable causes inconsistencies in the angle along its entire length during bending, which is an important factor affecting bending accuracy. Therefore, our 300T press brake comes equipped with this function as standard.

Photoelectric Safety Protection System

The entire machine is equipped with photoelectric safety protection systems at the front and rear to ensure efficient production and the personal safety of operators.

Point-to-point Protection On The Back

When the hydraulic press brake is operating, the point-to-point protection at the back can promptly respond to any abnormal contact entry. If someone mistakenly enters the working area at the rear of the press brake, it will immediately stop the bending machine to ensure the safety of individuals and property.

Tooling (Optional)

Get in touch

If you have any questions, please contact us, we will get back to you as soon as possible.

Phone

+86 189 5208 7956

Location

Nanjing, Jiangsu, China