With the wide array of press brakes available in today's market, each offering varying configurations and corresponding systems, selecting the most suitable bending machine can be a challenging task. Among these options, the torsion-bar bending machine and the electro-hydraulic press brake are frequently compared due to their similar functionalities but distinct components, systems, prices, and other factors.

To ensure a "future-proof" choice that combines high performance, cost-effectiveness, and ease of use, it is crucial to understand the differences between these two types of bending machines from various perspectives. In the following sections, we will explore the contrasts between the torsion-bar bending machine and the electro-hydraulic press brake, shedding light on their distinguishing characteristics.

Table of Contents

Comparison Between Torsion Bar Bending Machine and Electro-hydraulic Press Brake

Different Structural Principles

The design principles of the two models are different, resulting in different structures to ensure synchronization on both sides of the bending slider.torsion-bar bending machine uses torsion-bar to link left and right swing rods to form torsion-bar forcing synchronization mechanism to move up and down the oil cylinders on both sides.

Therefore, torsion-bar bending machine is a mechanical forced synchronization mode, and the parallelism of slide blocks cannot be automatically checked and adjusted.The electro-hydraulic press brake is to install a grating ruler on the slider or the bed, and the numerical control system can analyze the synchronization on both sides of the slider through the information fed back by the grating ruler at any time.

If there is an error, the numerical control system will adjust through the proportional hydraulic servo valve to synchronize the stroke on both sides of the slider.Numerical control system, hydraulic control valve set and grating ruler form the feedback closed-loop control of electro-hydraulic press brake.

Workpiece Precision

The parallelism of the slide determines the angle of the workpiece. The twist axis bending machine keeps the slide synchronized mechanically without real-time error feedback. The machine itself cannot make automatic adjustment, resulting in poor machining accuracy.In addition, its biasing ability is poor, because the torsion-bar bending machine forces the synchronization mechanism to move up and down on the oil cylinders on both sides through the torsion-bar, which will cause deformation of the torsion-bar if it is biased for a long time.

The electro-hydraulic press brake controls the sliding block synchronization through the proportional hydraulic valve group, and the grating scale provides real-time error feedback. If error grating scale feedback occurs, the system adjusts through the proportional valve to keep the sliding block synchronization and improve the machining accuracy.

Running Speed

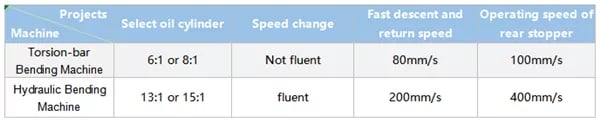

There are three points in the work of the machine that determine its running speed: (1) slider speed, (2) rear blocking speed, and (3) bending step.Torsional bending machine uses 6: 1 or 8: 1 oil cylinder, which is slow, while hydraulic synchronous bending machine uses 13: 1 or 15: 1 oil cylinder, which is fast.

Therefore, the fast down speed and return speed of the electro-hydraulic press brake are much higher than those of the torsion-bar bending machine.When the slider of the twist-axis bending machine goes down, although the speed has the function of fast down and slow down, the speed of fast down and return is only 80mm/s, and the speed conversion is not smooth.

The running speed of the rear stopper is only 100 mm/s.When the slide block of the electro-hydraulic press brake descends, the speed has the functions of fast descending and slow descending, the fast descending and return speeds can reach 200mm/s, and the speed conversion is smooth, thus greatly improving the production efficiency.

At the same time, the running speed of the rear stopper reaches 400 mm/s.(In the following figure, the left figure shows the oil cylinder of the torsion-bar bending machine, and the right figure shows the oil cylinder of the electro-hydraulic press brake)

Mechanical Strength

Due to its own design, the torsion-bar bending machine cannot bend under eccentric load. If bending under eccentric load for a long time, the torsion-bar will deform.The hydraulic synchronous numerical control bending machine does not have such problems. The Y1 and Y2 axes on the left and right sides operate independently, so it can bend under eccentric load.

Practical Operation

Most twist-axis bending machines are not equipped with numerical control system, let alone V-axis compensation, so when processing according to drawings, only the experience of old workers can be relied on to set out and do trial bending first.If you don't meet the standards and continue to try, this process not only produces waste materials, but also has a small selection range and a high salary when hiring operators.

Of course, if necessary, you can also choose to add a manual compensation system.The electro-hydraulic press brake is controlled by a professional numerical control system, has V-axis compensation, is simple to operate, and has low requirements on workers' experience.It has the function of simulating bending. It does not need lofting, only needs to correct the drawing input step size and directly bend.

Axis

The greater the number of control axes, the worse the effect. Generally, only the X and Y axes are controlled.The electro-hydraulic press brake is not controlled by the range of the number of axes, at least 3+1 axis, i.e. the automatic programming can meet high requirements, such as 4+1 axis, 5+1 axis, 6+1 axis, 7+1 axis, 8+1 axis, etc.Multi-axis linkage processing, after the workpiece is clamped on a bending machine for the first time, automatic tool change, rotating spindle head, rotating workbench and other operations can be carried out to complete multi-process and multi-surface composite processing, which not only has high smoothness but also greatly improves efficiency.

Advanced Selection

Torsional shaft bending machine can be equipped with some better configurations based on the original machine, such as common quick clamps, manual compensation, lifting stop fingers, ball screw and rear stop of linear guide rail, oil cooler, light curtain protection, etc.However, the electro-hydraulic press brake can be equipped with not only the above-mentioned basic configuration, but also a variety of advanced accessories.

For example, a better TYOKKO type quick clamp or AMADA type quick clamp is provided on the basis of common quick clamps.The lifting gear finger can not only be manually selected, but also an electric Z gear finger running on the guide rail through an AC motor can be selected.

Light curtain protection can also be replaced by more sensitive and safe laser protection.In addition, a servo pump control system with many advantages such as energy saving, low noise, fast stamping speed, higher accuracy and less oil consumption can be configured.Manipulators that can greatly improve production efficiency;Hydraulic clamping system;Follow-up feeding and laser angle detector.

The main difference between electro-hydraulic press brake and torsion-bar bending machine lies in whether there is feedback closed loop and whether there is compensation by electro-hydraulic press brake.

The two should be clearly distinguished.Torsional shaft bender mechanically adjusts the stroke of oil cylinder, while hydraulic bender controls the stroke by hydraulic pressure.Torsional bending machine is controlled by balance shaft, while electro-hydraulic press brake is synchronized by servo proportional valves on both sides.electro-hydraulic press brake refers to a combination of electrical and hydraulic advantages.

It has the advantages of high control precision, fast response speed, large output power, flexible signal processing and easy realization of feedback of various parameters.The working efficiency of one electro-hydraulic press brake can be equal to that of two to three torsion-bar bending machines.

In summary, the selection of a bending machine should be based on the actual processing requirements. The hydraulic servo synchronous bending machine offers high precision, real-time error feedback, and strong anti-deflection load capability for the bending slider.

In contrast, the torsional axis synchronous bending machine has lower precision, lacks error feedback mechanisms, and exhibits poor anti-deflection load capability for the bending slide block.

It is important to note that the hydraulic servo bending machine is more complex and typically more expensive than the torsional axis synchronous bending machine. Based on the information provided, you can choose the appropriate bending machine by considering the following specific aspects:

- Workpiece precision requirements (accounting for the precision deviation inherent in torsional axis bending machines).

- Daily operational duration of the machine (electro-hydraulic press brakes offer higher efficiency, potentially reducing working hours and labor costs).

- Operator experience level (torsional axis bending machines require debugging through experience, making them less suitable for novice operators, while electro-hydraulic press brakes are controlled by systems, making them more user-friendly and convenient).

- Failure rate considerations for previously purchased torsional axis bending machines. Frequent failures can reduce work efficiency and delay project timelines (electro-hydraulic press brakes typically have an extremely low failure rate).

| Twisted shaft bending machine | Electro-hydraulic press brake | |

| Workpiece precision | There is no too high requirement for workpiece precision. | High requirements for workpiece precision and attention to detail |

| Yield | The demand for workpieces is small and the requirement for work efficiency is not high. | There is a large demand for workpieces, which requires high work efficiency. |

| Practical Operation | There are many situations requiring manual operation, which is slightly inconvenient. | Intelligent numerical control, complete functions, easy to use |

| Applicable company | The new company was primarily a groping attempt at the beginning. | Large-scale old brands with equal emphasis on output and quality |

| Price | The price is lower, some accessories need to be matched separately. | The price is on the high side, but the function is complete and the quality is good. Generally speaking, the cost performance is very high. |

Overall

This comprehensive comparison will be extremely helpful for anyone looking to understand the differences between torsion axis and electro-hydraulic servo bending machines, and make an informed decision based on their specific needs and priorities.