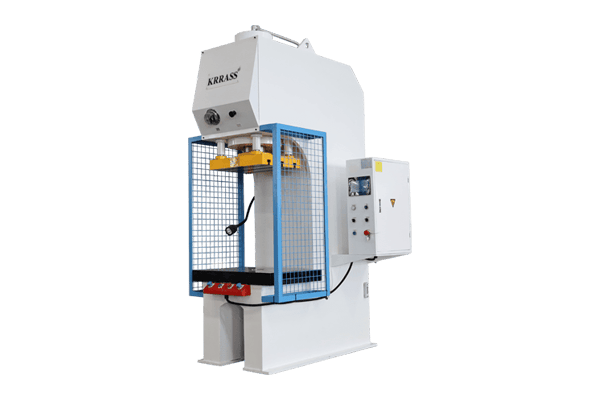

What is A Hydraulic Press

Hydraulic press, also known as oil hydraulic press, is a kind of machinery that uses liquid static pressure to process metal, plastic, rubber, wood, powder and other products. It is commonly used in pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, thin plate drawing, powder metallurgy, press fitting and so on.

Its principle is the use of Pascal's law made by the use of liquid pressure transmission machinery, many kinds. Of course, the use is also according to the need for a variety of things.

For example, there are two categories of hydraulic presses and hydraulic presses according to the type of liquid used to transmit pressure. The total pressure generated by hydraulic presses is larger and is often used for forging and stamping.

Forging hydraulic presses are divided into two types: die forging hydraulic presses and free forging hydraulic presses. Die forging presses use molds, while free forging presses do not use molds. The first 10,000-ton hydraulic press made in China is a free forging hydraulic press.

Application Range

The hydraulic forming process has a wide range of applications in the automotive, aviation, aerospace and pipeline industries, mainly for: circular, rectangular or shaped cross-section hollow structural parts that vary along the component axis, such as shaped pipe fittings for exhaust systems of automobiles; non-circular cross-section hollow frames, such as engine bays, instrument panel brackets, body frames (accounting for about 11%-15% of the mass of automobiles); hollow shaft-like parts and complex pipe fittings, etc.

The applicable materials for hydraulic forming process include carbon steel, stainless steel, aluminum alloy, copper alloy and nickel alloy, etc. In principle, all materials applicable to cold forming are applicable to hydraulic forming process. Mainly for auto parts factory, electronic factory, electrical factory, heat treatment factory, vehicle parts factory, gear factory, air conditioning parts factory.

Safe Operation

- Those who do not understand the structural performance or operating procedures of the machine should not start the machine without permission.

- The machine should not be overhauled and the mold adjusted during the working process.

- When the machine is found to have serious oil leakage or other abnormalities (such as unreliable action, high noise, vibration, etc.), it should be stopped to analyze the causes and try to eliminate them, and should not be put into production with illness.

- shall not overload or exceed the maximum eccentric distance used.

- strictly prohibited to exceed the maximum stroke of the slider, the minimum height of mold closure shall not be less than 600 mm.

- The grounding of electrical equipment must be solid and reliable.

- At the end of each day's work, I put the slider in the lowest position.

Maintenance System

- The working oil is recommended to use No. 32, No. 46 anti-wear hydraulic oil, and the oil temperature is within 15~60 degrees Celsius.

- The oil is strictly filtered before it is allowed to be added to the oil tank.

- Working fluid should be replaced once a year, of which first replacement time should not exceed three months.

- The slider should be lubricated frequently, the exposed surface of the column should be kept clean frequently, and oil should be sprayed before each work.

- The maximum allowable eccentricity of the concentrated load is 40 mm under nominal pressure of 500T. The eccentricity is too large to make the column strain or other undesirable phenomena.

- Every six months, calibrate and check the pressure gauge.

- When the machine is out of use for a long time, the surface of each part should be scrubbed clean and coated with anti-rust oil.

Secondary Maintenance

- Machine tools run 5000 hours for secondary maintenance. Maintenance workers as the main, operating workers to participate. In addition to the implementation of the first level of maintenance content should do following work, and mapping of wearing parts, spare parts.

- First cut off power for maintenance work.

- Crossbeam column guide: check and adjust the row hanging crossbeam plane, column guide, guide bush, slider, platen, so that it can achieve smooth movement and meet the process requirements. Repair or replace defective parts.

- Hydraulic lubrication: disassemble and clean, overhaul solenoid valve, grind valve, spool. Then clean and check the oil pump cylinder plunger repair light burr, replace the oil seal. Then calibrate the pressure gauge. According to the actual situation to repair or replace serious wear parts. Finally drive to check the oil cylinder, plunger running smoothly, no crawl. The support valve can make the movable beam stop at any position accurately and pressure meets the process requirements.

- Electricity: first clean the motor, check the bearings and update the grease. Then repair or replace damaged components. Make sure the electrical meets the requirements of the equipment integrity standard.

- Accuracy: Calibrate the machine level and check and adjust the repair accuracy. Make sure that the accuracy meets the requirements of the equipment integrity standards.

Hydraulic machine maintenance and maintenance or need dedicated, professional, full-time to maintain, so that you can use it longer!

Common Failures

Metal extrusion hydraulic press operation, sometimes there will be bolts fall off and fall into the hydraulic cylinder to the plunger wall causing serious scratches. After the problem occurs, the traditional method simply can not achieve on-site repair, can only be disassembled and transported to the manufacturer for patch welding processing or scrap replacement.

As there are no spare parts to replace, time to re-produce parts or return to the factory for repair cannot be controlled, and the long downtime causes serious economic losses to the enterprise, and also pays high processing or repair costs. In order to meet the requirements of continuous production, it is necessary to find convenient, simple and effective maintenance methods to solve the equipment problem, minimize downtime and reduce repair and maintenance costs. The polymer composite method can be used for on-site repair.

Operation Steps

- Oxy-acetylene flame baking scratch parts (master the temperature, to avoid surface annealing), the perennial seepage of metal surface oil baked out, baked to no sparks around.

- Surface treatment of the scratched part with angle grinder, grinding depth of more than 1 mm, and along the outer wall of the cylinder barrel grinding groove, preferably dovetail groove. Drill deeper at both ends of the scratch to change the force.

- Clean the surface with degreasing cotton dipped in acetone or anhydrous ethanol.

- Apply the blended repair material to the scratched surface; the first layer should be thin, even and all covering the scratched surface to ensure the best bond between the material and the metal surface, then apply the material to the whole repair area and press it repeatedly to ensure the material is filled and reach the required thickness, making it slightly higher than the surface of the cylinder outer wall.

- It takes 24 hours for the material to fully reach all properties at 24℃, in order to save time, you can increase the temperature by tungsten halogen lamp. for every 11℃ increase in temperature, curing time will be shortened by half, the best curing temperature is 70℃.

- After the material curing, use fine abrasive stone or scraper to repair the material higher than the surface of the outer wall of the cylinder, the construction is finished.