When considering the purchase of a press brake, distinguishing between CNC press brakes and NC press brakes can often be perplexing. These two types of press brake machines exhibit several key differences. Today, we aim to elucidate these disparities and offer valuable insights to aid you in navigating your business endeavors. Specifically, we'll categorize torsion-bar type press brakes as "NC press brakes" and electro-hydraulic type press brakes as "CNC press brakes." By understanding these distinctions, you'll be better equipped to make informed decisions as you embark on your business journey.

Basic Overview

NC and CNC press brakes represent advanced bending technologies controlled by numerical control systems. NC, or Numerical Control, allows machines to execute bending operations based on preset parameters or computer programs, eliminating the need for manual intervention. On the other hand, CNC, or Computer Numerical Control, empowers operators to program various bending parameters directly into the machine's controller, enabling precise and efficient execution of repetitive bends.

Compared to traditional manual or semi-automatic bending machines, CNC press brakes offer superior levels of automation and accuracy. They can autonomously complete entire bending processes without requiring human intervention or additional machinery to handle metal sheets or wires, thereby reducing labor costs and increasing productivity.

It's important for businesses to choose the right bending machine to ensure optimal production efficiency, quality, and cost control. Factors to consider include:

- Production Volume and Complexity: Assess the volume and complexity of bending tasks required for your operations. CNC press brakes are ideal for high-volume production and intricate bending geometries due to their advanced programming capabilities and precision.

- Budget and Investment: Consider your budget constraints and long-term investment goals. While CNC press brakes typically entail higher upfront costs, they offer greater efficiency and versatility, leading to potential cost savings and enhanced profitability over time.

- Automation and Operator Skill Level: Evaluate the level of automation required and the skill level of your operators. CNC press brakes streamline operations and reduce the need for manual intervention, making them suitable for environments with limited skilled labor or where consistency and precision are paramount.

- Maintenance and Support: Take into account maintenance requirements and the availability of technical support. CNC press brakes may require more specialized maintenance and technical expertise compared to NC press brakes, so ensure adequate support is available from the manufacturer or supplier.

- Future Growth and Flexibility: Anticipate future growth and evolving bending requirements. Choose a bending machine that offers scalability and flexibility to accommodate changing production needs and technological advancements.

By carefully considering these factors, businesses can select the right bending machine that aligns with their specific production requirements, maximizes efficiency, maintains quality standards, and controls costs effectively.

Main Differences of NC and CNC Press Brake

NC & CNC Press Brake: Operation Comparison

NC press brakes use a mechanical synchronization method with a Y-axis and a rear gauge X-axis for pressure movement. They consist of a worktable, a hydraulic system, clamps, and a rear gauge. NC press brakes employ a mechanical forced synchronization method, and the parallelism of the slide cannot be self-calibrated and adjusted. The stroke of the slide can be manually adjusted, and a wedge-type clamp compensates for higher bending precision.

In the case of CNC press brakes, two linear encoders are installed on both sides of the machine, and the CNC controller analyzes the synchronization of the slide based on feedback from these two linear encoders. If any errors occur, the controller makes adjustments through proportional valves to maintain slide synchronization. The CNC controller, hydraulic system, and linear encoders together form a closed-loop control system.

Structure Diffrence

The design principle for both machines is different, it results in the different synchronous structures on both sides of the ram. NC press brake adopts torsion shaft to connect the both sides of the ram and force the ram to move up and down synchronously, in this way, NC press brake uses the compulsive synchronous way mechanically, so the ram parallelism cannot be check and adjust by itself. For the CNC Press brake, two linear encoders are installed on the machine both sides and the CNC controller can analyze the synchronous condition on both sides of the ram by the feedback from both linear encoders. If there is some error, the controller will make the adjustment by the proportional valve to keep the synchronization of the ram. CNC controller, hydraulic system and the linear encodes consist of the closed loop control system.

Working speed

For the press brake, we are always talking about three speeds: Down speed, working speed and return speed. For NC Press brake, it will us 6:1 or 8:1 cylinder, for the CNC Press brake, it will use 13:1 or 15:1 cylinder, so CNC press brake will work faster than NC press brake. When NC press brake ram comes down, its down speed is around 80mm/s, the backgauge moving speed is around 100mm/s. But for CNC Press brake, its ram down speed will be up to 200mm/s and it can move very fluently during the speed change point. Its backgauge speed can be up to 400mm/s and it will improve the working efficiency obviously.

Bending Accuracy

When compared to NC press brakes, the slide opening height of NC press brakes is fixed, and it needs to move from the highest point to the lowest point each time it opens, which might lead to efficiency issues. The descent speed of the slide in NC press brakes is approximately 80mm/s, and the rear gauge movement speed is around 100mm/s. In contrast, CNC press brakes offer greater flexibility. The CNC controller allows precise control of the slide opening height using digital control, eliminating the need to return to the highest point each time and saving time, thereby improving processing efficiency. The slide descent speed can reach up to 200mm/s in CNC press brakes, with smooth movement even at variable points. The rear gauge speed can reach 400mm/s. Additionally, in terms of hydraulic cylinders, NC press brakes typically use 6:1 or 8:1 cylinders, while CNC press brakes use 13:1 or 15:1 cylinders. As a result, CNC press brakes have much faster idle and return speeds compared to NC press brakes.

Bending Angle Calibration

Bending Angle Calibration in NC Press Brakes: NC press brakes utilize basic Numerical Control (NC) systems, which lack real-time monitoring and automatic calibration features. Angle calibration typically involves manual intervention and operator expertise. Operators may need to employ angle measuring tools like protractors or angle gauges to manually assess the workpiece's angle and make necessary adjustments. The accuracy of this manual calibration process may vary and can be influenced by the operator's proficiency and experience level.

Bending Angle Calibration in CNC Press Brakes: In contrast, CNC press brakes are equipped with advanced Computer Numerical Control (CNC) systems that enable real-time monitoring and adjustment of angles during bending operations. These systems often incorporate angle sensors and feedback mechanisms to measure the actual bending angle of the workpiece and compare it to the predetermined angle. If any deviation is detected, the CNC system can automatically make minor adjustments to ensure the workpiece achieves the desired angle accurately. This automation process enhances angle calibration precision and diminishes the need for manual intervention by operators.

How To Program A CNC Press Brake

Programming a CNC press brake involves translating a design into a set of instructions that the machine can comprehend and execute accurately. Here's a breakdown of the process:

- Design Preparation: Start by creating or importing the CAD design of the workpiece, ensuring it includes all necessary dimensions, bending angles, and positional information.

- G-code Generation: Convert the design into machine-readable G-code, which contains detailed instructions for machine movements and bending operations. This step can be automated using specialized CAM software or manually by writing G-code.

- Material and Tool Selection: Before programming, choose the appropriate materials and cutting tools, as they will impact bending parameters and forces. Specify bending angles, bend locations, tool positions, and required bending forces during programming.

- G-code Upload: Upload the generated G-code to the CNC's controller. This typically involves storing the G-code file on a USB drive or uploading it through a network connection.

- Workpiece and Tool Setup: Set up the workpiece and tools on the CNCpress brake machine before executing the program. Ensure the workpiece is securely clamped and correctly positioned on the machine's worktable, and verify that the tools are properly installed.

- Program Execution: Start the CNC bending machine, load the G-code program, and follow the instructions displayed on the controller interface. The machine will execute movements and operations based on your programmed instructions.

- Monitoring and Adjustment: Monitor the bending process to ensure smooth operation. Make adjustments as necessary during the operation using the controller interface to check the quality and dimensions of the workpieces.

- Completion and Shutdown: Once all workpieces are completed, stop the machine, remove the workpieces, clean and mark them as needed, and shut down the CNC bending machine.

How To Choose Controller For NC & CNC Press Brake

NC Press brake system options

1.ESTUN E21 Control

- The high-definition hydraulic display has two languages, Chinese and English, and one page displays programming parameters, making it faster and more convenient to write programs.

- Intelligent positioning of X and Y axes can also be adjusted manually as required, eliminating the mechanical manual positioning device.

- Built-in pressure holding time, unloading delay setting function, the operation is simpler, and there is no need for a time relay to reduce the cost.

- With parameter one-key backup and restore function, parameters can be restored at any time as needed to reduce maintenance costs.

Support multi-process programming, complex workpieces can be processed at one time, improving production efficiency and processing accuracy. - All the buttons on the panel are micro switches, which have been strictly tested for EMC, high and bottom temperature, and vibration. Ensure product stability and service life.

- Passed CE certification to meet the needs of overseas markets.

2.ESTUN E310P Control

- 4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Automatic calculation of the block position, according to the bending angle, material, thickness and mold parameters.

- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Optional hydraulic or mechanical to control the C-axis.

- Program in absolute value or angle.

- Materials and die informations are programable.

- Language setting and unit setting.

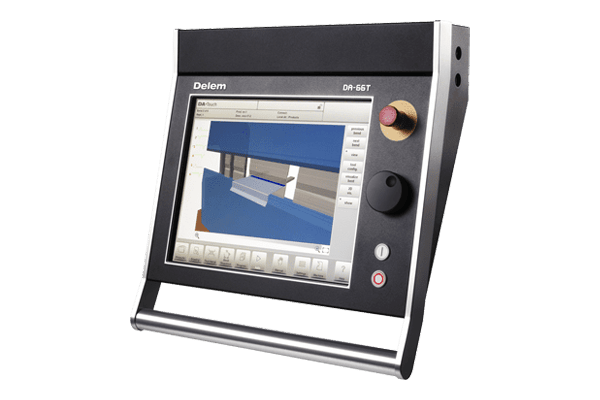

3.Holland DELEM DA41T

- Industrial-grade high-quality touch screen control

- 7″ widescreen high resolution color TFT

- Slider Y axis control

- Backgauge X axis control

- R axis control

- Program memory for 100 programs

- Angular programming

- Tool programming

- Manually move all axes

- USB memory stick interface

4.Switzerland Cybtouch 8

- Large screen, high definition and contrast touch screen system.

- Convenient interface, clear display and large icon buttons.

- The EasyBend page is very convenient for single-step bending.

- Perfect programming can improve the efficiency of batch multi-step bending.

- Online help and pop-up prompts make the software interface very friendly.

- Support multiple languages.

- Use PC or laptop to upgrade and transfer data through wireless software

Selection of CNC press brake system

1.Holland DELEM DA53T

- “Hot-key” touch navigation

- 10.1″ high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as

- open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

2.Holland DELEM DA58T

- 2D graphical touch screen programming

- 15″ high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

3.Holland DELEM DA66S

- 2D graphical touch screen programming mode

- 3D machine representation, in simulation and production

- 24″ high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control’s multitasking environment

- Sensor bending & correction interface

- Profile-S2D offline software

4.Holland DELEM DA69S

- 3D and 2D graphical touch screen programming mode

- 3D visualization, including 3D machine representation, in simulation and production

- 24″ high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control’s multitasking environment

- Sensor bending & correction interface

- Profile-S3D offline software

5.Switzerland Cybtouch 12ps

- Large, vivid and high-contrast fully touchscreen.

- Simple pages, clear display, large keys.

- Intuitive user-friendly interface.

- Complete programming for efficient mass-production with multiple bends.

- Easy single bends with EasyBend page.

- On-line help and interactive warning pop-ups.

- Comfortable wireless data backup and software updating using PC or Notebook.

- Large variety of languages available.

6.Switzerland Cybtouch 15ps

- 15” modern streamlined glass surface touch screen that can be used with gloves.

- User friendly HMI thanks to intuitive programming and easy to setup with dedicated wizards (autotuning).

- 2D graphical profile drawing (Touch Profile) and precise 2D program creation.

- Automatic bending sequence calculation.

- Easy single bends thanks to the EasyBend page.

- Wide storage capacity.

- Internal backup and restore functions.

- Wireless communication for extended diagnostics and updates (with laptop).

Conclusion

Through the above article, you must have some understanding of the difference between the two. In fact, the difference between the two is far more than that. Knowing the difference between the two can help you make the best decision.

Krrass is a renowned company specializing in the manufacturing and distribution of sheet metal fabrication machinery. With a global presence and a reputation for excellence, Krrass has established itself as a leading provider of high-quality equipment for a diverse range of industries. If you need any metal processing equipment, pls feel freel to ask us, we are a manufacture saling kinds of NC and CNC press brakes, fiber laser cutting machines, plate rolling machines, etc.