What Is A NC Press Brake

A NC press brake is a type of machine tool used in metalworking and sheet metal fabrication processes. It is specifically designed for bending and shaping sheet metal into desired shapes and angles. Unlike conventional manual press brakes, NC press brakes are equipped with numerical control systems that allow for automated operation and precise control over bending parameters.

key components of a NC press brake

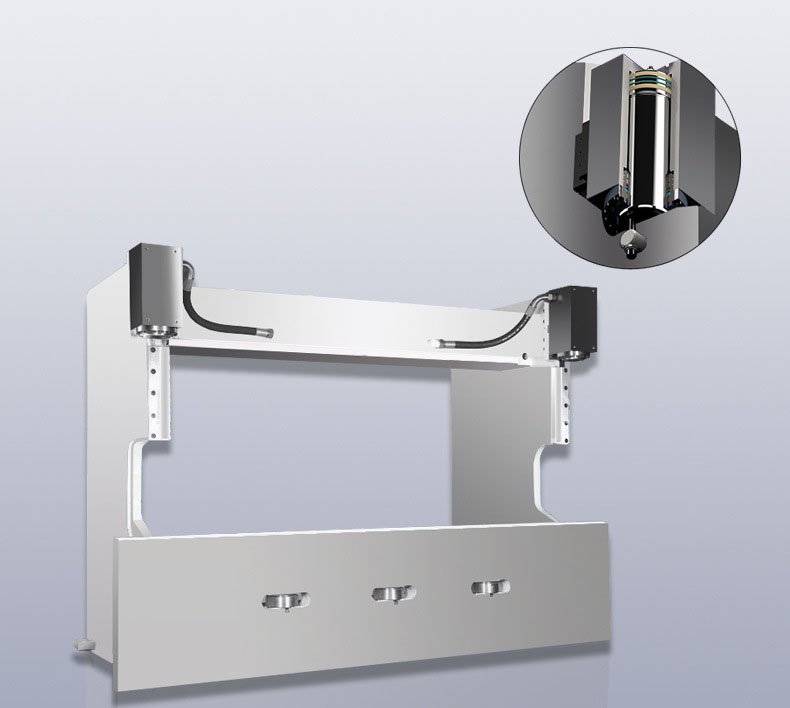

Frame: The frame provides the structural support and rigidity necessary for bending operations. It houses the hydraulic or mechanical mechanisms responsible for applying force to the workpiece.

Bending Tooling: The machines use a variety of tooling, including upper and lower dies, to perform bending operations. These tooling sets are selected based on the specific bending requirements of the workpiece.

Backgauge System: A backgauge system consists of a series of adjustable stops or fingers positioned behind the bending area. It helps accurately position the workpiece for consistent and repeatable bends.

Hydraulic System: Most machines are powered by hydraulic systems that generate the force needed to bend the metal. The hydraulic system includes pumps, cylinders, valves, and actuators that control the movement of the ram and bending tooling.

Numerical Control (NC) System: The NC system of a press brake consists of electronic controls, motors, and a user interface that allows operators to program and control bending operations. It typically includes a touchscreen display or control panel for entering bending parameters such as bend angle, bend length, and material thickness.

Safety Features: NC press brakes are equipped with safety features such as interlocks, light curtains, and emergency stop buttons to ensure operator safety during operation.

NC press brakes offer several advantages over manual press brakes, including faster setup times, increased productivity, higher accuracy, and the ability to produce complex bends and shapes. They are commonly used in various industries such as automotive, aerospace, electronics, and construction for manufacturing a wide range of metal components and products.

This article explore each part in more detail.

Press Brake Body

The NC press brake‘s frame is constructed from the welding of the left and right upright plates, the worktable, supporting bodies, and fuel tanks. The worktable is positioned beneath the left and right uprights, while the fuel tank is welded with the uprights.

This design enhances the frame’s rigidity and strength, as well as expands the area for the dissipation of heat from the hydraulic oil.

Features of the Press Brake Structure:

Press brake structure is the frame that supports the ram and it is welded to the lower table, it usually consists of two parts with a “C” shape in the back.

The fully welded structure provides sufficient strength and rigidity.

The hydraulic oil is transmitted upwards, with the cylinders on both ends of the press brake installed on the slider, which directly drives the sliding work.

The ram uses torsion to ensure synchronization.

A mechanical stopper is used, providing stability and reliability.

The ram stroke is adjusted by the controller and can be fine-tuned manually, with a counter display.

The wedge-shaped crowning design ensures higher bending accuracy.

Press Brake Controller

Press brake numerical control is a common featureof machines tools.

Numerically controlled machine tools or NC machine tools are machine tools whose operation is controlled by a computer integrated into the machine.

This computer governs the movements and functions of the machine in accordance with a specific working program.

Thanks to an encoder in the numerical control, it measures the positions of its moving parts and activates actuators, (motors, hydraulic pistons or others), which control the machine movements and position the tool at a specific arbitrarily chosen point.

A given movement of the machine measured by an encoder and controlled by a computer by means of a motor that can position the machine precisely at an arbitrary point along the available stroke is called controlled axis or simply machine axis.

In addition to selecting the dimensions or features of a press brake, a buyer can choose from a number of different numerical control types, which are, mounted at one end of the machine, and are the main control point from which programming of the entire system takes place.

Numerical control types on the market differ in the number of axes they can control and in their ability to produce a video simulation of the bending sequence.

Press Brake Ram

The ram of the press brake is constructed from a solid steel plate and is connected to the piston rod in the center of the left and right hydraulic cylinders. The cylinder is secured to the connecting plate of the left and right wall plates and the piston rod is driven by hydraulic power to move the slider up and down.

To ensure accurate positioning of the ram at the upper dead point, grating rulers are placed on both sides of the ram to transmit position information back to the NC controller, which then adjusts the position. This also ensures the synchronized operation of the ram.

The ram utilizes hydraulic transmission and its system consists of the ram, hydraulic cylinder, and a mechanical stopper for fine adjustment. The left and right cylinders are attached to the frame, and the piston is driven by hydraulic pressure to move the ram up and down. The mechanical stopper is controlled by the numerical control system.

Stroke

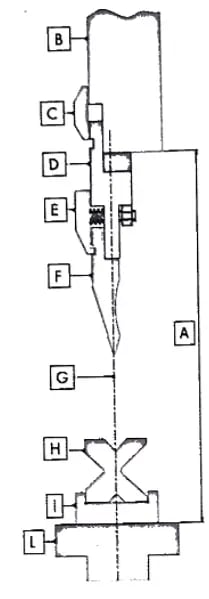

Stroke indicates the maximum available movement along the Y axis. This

dimension is extremely important for checking the possibility of using tall

punches. In such cases the operator must check that: [Daylight – die height

(from base to V bottom) – punch height (from upper beam to punch tip) –

sheet metal thickness < machine stroke.

The diagram on the above shows a cross section of a press brake with a Promecam-Amada standard tool.

A → daylight: distance between upper beam and table

B → upper beam: upper part of a press brake

C → upper beam clamp: clamp mounted on the upper beam to hold intermediates

D → intermediate: part for mounting punches on the upper beam

E→ intermediate clamp: clamp mounted on the intermediate to hold punches

F→ punch: upper tool

G → machine axis: bending axis passing through the punch tip and the vee center of the die

H → die: lower tool

I→ die holder: part for clamping dies

L→press brake table: table for supporting dies.

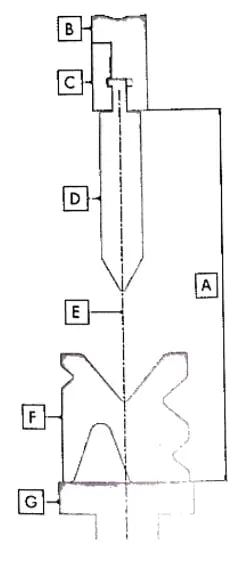

The image above, on the other hand, shows a press brake with an axial tool (Trumpf, Beyeler, etc…) In this case the punch is clamped directly into the upper beam and the press brake axis goes through both punch and tip.

A → daylight: distance between upper beam and table

B → upper beam: upper part of a press brake

C → upper beam clamp: clamp mounted on the upper beam to hold punches

D → punch: upper tool

E→ machine axis: bending axis going through the punch tip and the vee center of the die

F → die:lower tool

G → press brake table: table for supporting dies.