Table of Contents

NC vs. CNC Bending Machine

NC and CNC bending machines represent machines employed in bending processes controlled by a numerical control system. Numerical Control (NC) signifies the capability of these machines to execute bending operations through computer programs or predetermined parameters without manual intervention. In contrast, Computer Numerical Control (CNC) utilizes advanced technology to govern and carry out bending operations. Through CNC systems, operators can input various bending parameters for the workpiece, which the controller then applies, ensuring precise and efficient execution of repetitive bends.

Compared to conventional manual or semi-automatic bending machines, CNC press brakes provide elevated levels of automation and accuracy. These machines can independently complete the entire process without requiring manual intervention or the presence of additional equipment for feeding metal sheets or wires, ultimately reducing labor costs. It's worth noting that NC press brakes fall under the category of CNC press brakes.

To optimize production efficiency, maintain quality standards, and exercise cost control, businesses must carefully consider their choice of bending machine.

What is the Operation Mechanism of NC and CNC Bending Machines?

NC press brakes use a mechanical synchronization method with a Y-axis and a rear gauge X-axis for pressure movement. They consist of a worktable, a hydraulic system, clamps, and a rear gauge. NC press brakes employ a mechanical forced synchronization method, and the parallelism of the slide cannot be self-calibrated and adjusted. The stroke of the slide can be manually adjusted, and a wedge-type clamp compensates for higher bending precision. In the case of CNC press brakes, two linear encoders are installed on both sides of the machine, and the CNC controller analyzes the synchronization of the slide based on feedback from these two linear encoders. If any errors occur, the controller makes adjustments through proportional valves to maintain slide synchronization. The CNC controller, hydraulic system, and linear encoders together form a closed-loop control system.

How To Use CNC Bending Machines?

First, it is essential to prepare for the task, including wearing appropriate personal protective equipment and ensuring a clean and organized work area. Prepare the necessary metal materials, tools, and workpieces, and securely clamp the workpiece to the machine's worktable to ensure stability.

Next, select the right cutting tools and bending dies and install them on the CNC bending machine. Proceed by inputting the parameters of the workpiece through CNC programming, including bending angles, positions, and bending forces, so the machine knows how to operate. Start the CNC machine, load the CNC program, and enter the relevant parameters through the controller interface. The machine will then execute the bending operations based on the G-code or CAM instructions, and you can monitor the machine's operation through the controller interface.

During operation, regularly inspect the quality of the workpieces by using measuring instruments to check dimensions and angles to ensure they meet design requirements. If necessary, adjust the tools or reprogram the machine.

Finally, once all workpieces are produced, stop the machine's operation, remove the workpieces, clean and mark them (if required), and shut down the CNC bending machine. Perform necessary maintenance to ensure the machine's proper operation and longevity.

How To Program CNC Bending Machines?

CNC bender programming is the process of translating a design into a series of instructions that the machine can understand and execute. Here are the steps:

Begin by creating or importing the CAD design of the workpiece, making sure it includes necessary dimensions, bending angles, and position information.

Next, convert this design into machine-readable G-code. G-code contains detailed instructions for machine movements and bending operations. This step can be automated using specialized CAM software or done manually by writing G-code.

Before programming, select the appropriate materials and cutting tools, as they will impact bending parameters and forces. Specify bending angles, bend locations, tool positions, and required bending forces during programming.

Once the G-code is generated, upload it to the CNC bending machine's controller. This typically involves storing the G-code file on a USB drive or uploading it through a network.

Set up the workpiece and tools on the CNC bending machine before executing the program. Ensure the workpiece is securely clamped and correctly positioned on the machine's worktable, and that the tools are properly installed.

Start the CNC bending machine, load the G-code program, and follow the instructions displayed on the controller interface. The machine will execute movements and operations based on your programming.

Monitor the bending process to ensure everything is running smoothly. Adjustments can be made during the operation if necessary. Use the controller interface to check the quality and dimensions of the workpieces.

Finally, when all workpieces are completed, stop the machine, remove the workpieces, clean and mark them as needed, and shut down the CNC bending machine.

CNC bender programming requires skill and experience to ensure high-quality and precise bending operations. Proper programming can improve production efficiency, reduce costs, and ensure compliance with design requirements.

Comparison Of Numerical Control Systems

NC Press Brake Numerical Control System

NC bender are two-axis programmable tools that use torsion bars for synchronization. NC, or Numerical Control, involves using a numerical control system to manage the machine's movements. NC press brakes usually utilize pre-written numerical programs to control bending operations. These programs contain a series of coordinates and motion instructions to determine the shape and bending angles of the work piece. Operators need to manually input these numerical programs, typically using the machine's control panel or an external computer. NC press brakes are generally less expensive than CNC press brakes but require relatively higher operator skills. NC press brake controllers can be programmed for complex bending sequences, e.g., Delem 41, E21, Cyblec. They still offer an accurate and cost-effective option.

CNC controllers enable 2D and 3D simulations, ensuring complex bend shapes are thoroughly considered and providing optimized programming solutions, significantly enhancing production efficiency and work piece quality. CNC press brakes employ powerful algorithms in the control system to analyze the machine's operating state, allowing for precise adjustment of various parameters, and leaving room for improvement in the press brake's performance. Continuous innovations in numerical control system technology have led to widespread applications of CNC press brakes, such as in bending cell centers that can work in conjunction with robots. Advanced CNC systems also provide safety features, laser protection, light curtains, angle checks, laser checks, and material following devices, and offer multiple language options and highly intelligent DXF file inputs. These features play a crucial role in practical bending work, genuinely assisting in sheet metal bending operations. CNC press brakes' CNC systems allow for multiple programming and have storage capabilities. The larger the system's storage capacity, the more programs the machine can store. If manufacturers need to bend various specifications or complex work pieces, it's better to choose a CNC system to complete batch production efficiently. NC systems have no storage function.

Bending Accuracy And Speed Comparison

Bending Accuracy

The parallelism of the slide affects work piece precision. NC press brakes use mechanical synchronization maintained by a torsion bar and do not have real-time error feedback, nor can they self-adjust, resulting in lower bending accuracy. For CNC benders, the controller maintains slide synchronization through proportional valves based on feedback from linear encoders that analyze synchronization on both sides of the slide. If there is any error, the linear encoders provide feedback to the controller, which then sends signals to proportional valves for adjustment, enhancing bending accuracy.

Working Speed

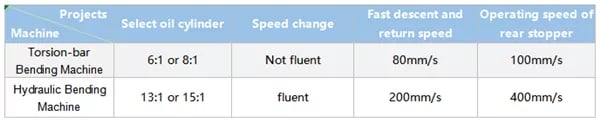

When compared to NC press brakes, the slide opening height of NC press brakes is fixed, and it needs to move from the highest point to the lowest point each time it opens, which might lead to efficiency issues. The descent speed of the slide in NC press brakes is approximately 80mm/s, and the rear gauge movement speed is around 100mm/s. In contrast, CNC press brakes offer greater flexibility. The CNC controller allows precise control of the slide opening height using digital control, eliminating the need to return to the highest point each time and saving time, thereby improving processing efficiency. The slide descent speed can reach up to 200mm/s in CNC press brakes, with smooth movement even at variable points. The rear gauge speed can reach 400mm/s. Additionally, in terms of hydraulic cylinders, NC press brakes typically use 6:1 or 8:1 cylinders, while CNC press brakes use 13:1 or 15:1 cylinders. As a result, CNC press brakes have much faster idle and return speeds compared to NC press brakes.

Bending Angle Calibration Comparison

Bending Angle Calibration in NC Press Brakes

NC press brakes use relatively basic Numerical Control (NC) systems, often lacking real-time monitoring and automatic calibration functions. Angle calibration usually requires more manual intervention and operator skill. Operators may need to use angle measuring tools such as protractors or angle gauges to manually measure the work piece's angle and make manual adjustments. The accuracy of this manual calibration process may be lower and can be influenced by the operator's experience and skill level.

Bending Angle Calibration in CNC Press Brakes

CNC press brakes are equipped with advanced Computer Numerical Control (CNC) systems that can monitor and adjust angles in real time during the bending process. CNC press brakes typically feature angle sensors and feedback systems that measure the actual bending angle of the work piece and compare it to the preset angle. If the actual angle does not match the preset angle, the CNC system can automatically make minor adjustments to ensure the work piece achieves the desired angle. This automation process often provides higher angle calibration accuracy and reduces the need for operator intervention.

NC Press Brake Features

- Traditional structure using torsion bars for Y-axis synchronization

- Standard X and Y axes

- ESTUN E21 NC Control Unit

- Motorized Back Gauge

- Upper punch compensation

- FIRST Valves (U.S.A)

- Full-length multi-V die, Upper punch with segmentation 835mm

- NOK Seal Ring

- Side and rear safety protection

- Mechanical crowning system manually operated

- Electrical cabinet with Telemecanique Schneider, Esautomotion, ABB components

CNC Press Brake Features:

- ESA CNC Control Unit S630 (OptionalDELEM DA53T , 58T , 66T , 69T , 66S , ESA 630 , 640 ,860)

- 4+1 or more axis CNC control

- Y1 and Y2 precision ram positioning

- Standard X and R axes

- CNC dynamic crowning

- Large open height, stroke, and throat depth

- NOK seal ring

- Schneider and ABB electric components

- Siemens motor

- Side and rear safety protection

- Sheet metal frontal supports

- SUNNY Pump

- Ball screw and linear guide

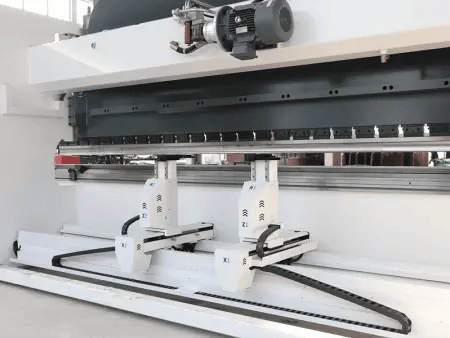

- Rear back gauge fingers with 3 blocks and double linear guide

Practical Operation

NC press brakes lack a numerical control system and V-axis compensation. When bending new work pieces, experienced operators can only resort to trial bending, which can be wasteful in terms of materials and may require higher wages for skilled operators. CNC press brakes, equipped with CNC control systems and V-axis compensation, offer a simpler operation that requires lower operator experience. CNC controllers include analog bending functions, eliminating the need for trial bending and allowing for direct bending.

Price And Cost

In reality, if the machine capacity is less than 200 tons, CNC press brakes can be priced at more than twice the cost of NC press brakes. However, if the bending machine capacity exceeds 200 tons, CNC press brakes can be priced lower by up to half the cost of NC press brakes. Therefore, if the press brake has a higher production capacity, opting for a CNC press brake is often the better choice. Overall, CNC press brakes are typically priced higher than NC press brakes due to their advanced control systems, higher levels of automation, and improved performance. The specific price difference depends on the machine's model, specifications, and features, as well as market competition and supply-demand conditions. When purchasing a press brake, it's essential to balance price and performance according to your budget and production requirements.

Applications Of Press Brakes

Applications of NC Press Brakes

Small-batch production: NC press brakes are typically suitable for producing relatively low quantities of parts, such as specific custom orders or small-scale projects.

Lower precision requirements: NC press brakes are a cost-effective choice for applications that do not require high precision.

Simple parts: They are commonly used for manufacturing simple metal parts, such as flat plates, straight angles, and basic bends.

Manual programming: Operators need to manually input coordinates and programs, making them suitable for users with some numerical control programming experience.

Cost-effectiveness: NC press brakes are generally more affordable and are suitable for situations with budget constraints.

Applications of CNC Press Brakes

Large-batch production: CNC press brakes are suitable for large-scale production needs, as they can enhance production efficiency and consistency.

High precision requirements: For industries that require high precision and accuracy in part manufacturing, such as aerospace, shipbuilding, automotive, and electronics, CNC press brakes are the preferred choice.

Complex parts: CNC press brakes can handle complex part bending, including parts with multiple bending angles and curves.

Automation: They typically offer higher levels of automation, capable of automatically executing bending tasks, reducing the need for operator intervention.

Higher cost: CNC press brakes are generally priced higher due to their advanced control systems and capabilities. They are typically suitable for applications with high production demands and precision requirements.

Of course, any factory that requires a bending machine can choose a CNC press brake, as it is suitable for various types of sheet metal bending processes.

Decorative Industry: Cabinets, cupboards, elevators, doors, windows, curtain walls, etc.

Construction Industry: Steel structures, towers, bridges, etc.

Machinery Manufacturing: Environmental protection equipment, livestock equipment, solar equipment, insulation materials, transformers, etc.

Electrical and Power Industry: Electric poles, lamp posts, electrical equipment, electronic devices, etc.

Conclusion

CNC press brakes offer high precision, real-time error feedback, and robust resistance to off-center loads in bending slides. On the other hand, NC press brakes provide lower precision, lack error feedback, and have weaker resistance to off-center loads on bending slides. Additionally, CNC press brakes are more complex and expensive compared to NC press brakes. In summary, the choice of a press brake depends on specific machining requirements. If you have any further questions regarding whether to choose an NC or CNC press brake, please feel free to contact KRRASS.