Table of Contents

What Is A Press Brake

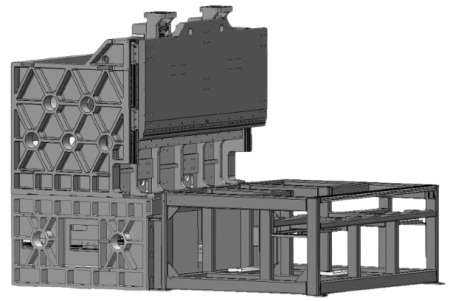

A press brake is a machine tool used in metalworking to bend and form sheet metal and plate materials. It utilizes a hydraulic or mechanical mechanism to apply force to a workpiece, causing it to bend along a straight axis. Press brakes are widely used in various industries, including manufacturing, automotive, aerospace, construction, and more.

What Is A Panel Bender

A panel bending machine, also known as a folding machine or panel folding machine, is a type of machine tool used in metalworking to bend and fold sheet metal panels into specific shapes. Unlike press brakes, which primarily bend sheet metal along a straight axis, panel bending machines are designed to create complex bends, curves, and flanges in sheet metal panels.

What's the Differences betwen Them

Clamping System: Panel bending machines typically use a clamping system to hold the sheet metal panel securely in place during the bending process. This ensures precise and consistent bends without slippage.

Folding Beam: The folding beam, also known as the bending beam or folding blade, is the primary tool used to bend the sheet metal. It moves vertically and horizontally to create bends of various angles and shapes.

Backgauge System: Similar to press brakes, panel bending machines may feature a backgauge system to accurately position the sheet metal panel for bending. This ensures repeatability and consistency in the bending process.

CNC Control: Many modern panel benders are equipped with computer numerical control (CNC) systems, allowing for automated operation and programming of complex bending sequences. CNC panel bending machines offer precise control over bend angles, lengths, and depths, as well as the ability to store and recall bending programs.

Tooling: Panel bending machines may utilize various tooling options to accommodate different bending requirements, such as straight bends, radius bends, hemming, and flanging. The tooling can be easily changed or adjusted to achieve different bending configurations.

How to Choose Between the Two Mchines

Choosing between a press brake or a panel bending machine depends on various factors including the specific requirements of your metal fabrication projects, budget, available space, and production volume. Here are some considerations to help you make the decision:

Bending Complexity: Panel benders are ideal for projects that require complex bends, curves, and shapes in sheet metal panels. If your projects involve intricate geometries or multiple bends with different angles, a panel bender may be the better choice. Press brakes, on the other hand, are better suited for simpler straight-line bends and angular bends.

Production Volume: Consider the volume of sheet metal parts you need to produce. Panel benders are generally faster and more efficient for bending large quantities of panels with complex shapes due to their automated operation and quick setup times. Press brakes may be more suitable for lower-volume production runs or for projects with simpler bending requirements.

Accuracy and Repeatability: Panel bending machines typically offer high accuracy and repeatability in bending due to their CNC-controlled operation and precise tooling. If your projects require tight tolerances and consistent bending results, a panel bender may be the preferred option. Press brakes can also achieve high accuracy with skilled operators and proper setup, but may require more manual adjustments for complex bends.

Floor Space: Consider the available floor space in your workshop or manufacturing facility. Panel benders generally have a smaller footprint compared to press brakes, making them suitable for smaller workshops or tight production environments. Press brakes may require more space for setup, tooling storage, and material handling.

Versatility: Press brakes offer greater versatility in terms of bending capabilities, as they can accommodate a wide range of materials, thicknesses, and bending configurations. With the right tooling and setup, press brakes can handle both simple and complex bending tasks. Panel bending machines, while specialized for panel folding, may have limitations in terms of material thickness and bending angles.

Cost: Consider your budget and the overall cost of ownership, including initial purchase price, maintenance, and operating costs. Panel benders tend to be more expensive upfront due to their advanced CNC technology and automation features. Press brakes may offer a more cost-effective solution for smaller-scale operations or projects with simpler bending requirements.

Ultimately, the choice between a press brake and a panel bender depends on your specific production needs, budget, and long-term goals. It's important to carefully evaluate your requirements and capabilities before making a decision. Additionally, consulting with equipment manufacturers or industry experts can provide valuable insights and guidance in selecting the right machine for your metal fabrication applications.

Conclusion

In summary, while both press brakes and panel bending machines are used for metal bending applications, press brakes are more versatile for complex bending operations and offer greater precision and flexibility. Panel benders are specialized machines designed specifically for folding large panels or sheets with straight-line bends.