cNC Press Brake For Sale

The press brake machine is a vital tool in the metal fabrication industry, used to bend and shape metal sheets with precision. It consists of a bed, horizontal lower die, and vertical upper die, brought together by hydraulic pressure to bend the metal sheet. Operated by a hydraulic control system, it can be adjusted for different shapes, lengths, and thicknesses of metal sheets.

KRRASS, a top-rated CNC press brake manufacturer in China, offers options like the Economical type with 2D program function and 4-6 axis backgauge system. The Smart type comes with DELEM Controllers, while the Econom type is an economical option for startups. KRRASS is committed to manufacturing high-quality brake press machines and custom toolings. Contact us for a quote.

Get in touch

If you have any questions, please contact us, we will get back to you as soon as possible.

Phone

+86 189 5208 7956

Location

Nanjing, Jiangsu, China

Social

Structural features

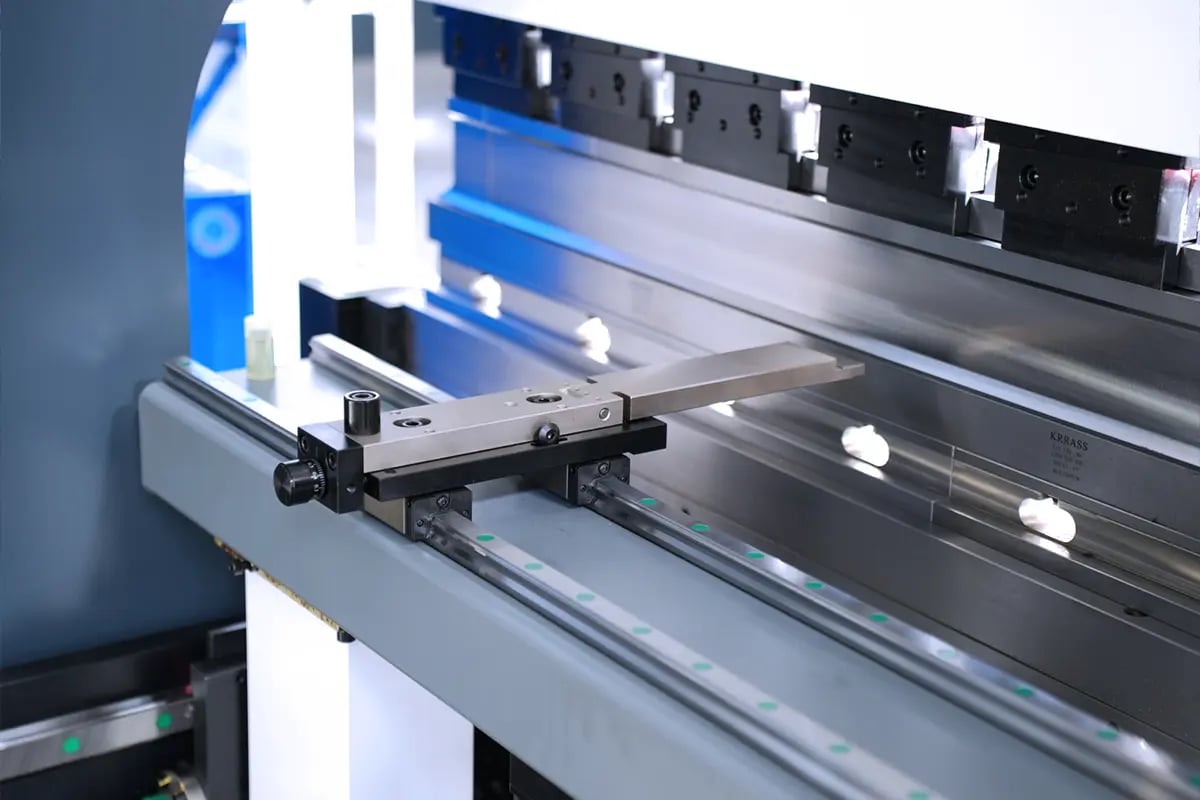

Backgauge Axis

The press brake backgauge, a crucial element in metal fabrication machinery, is the system that automatically positions the workpiece accurately for bending operations. Typically equipped with multiple axes, these backgauges can be controlled to adjust the workpiece's position, with the number of axes varying based on the press brake machine's complexity. The X-Axis facilitates horizontal movement along the press brake bed, controlling the workpiece's left-to-right position. The R-Axis governs vertical movement, adjusting the backgauge fingers' height to accommodate varying material thicknesses. Some press brakes feature a Z-Axis, controlling the depth of penetration of the backgauge fingers into the material.

Learn More >>

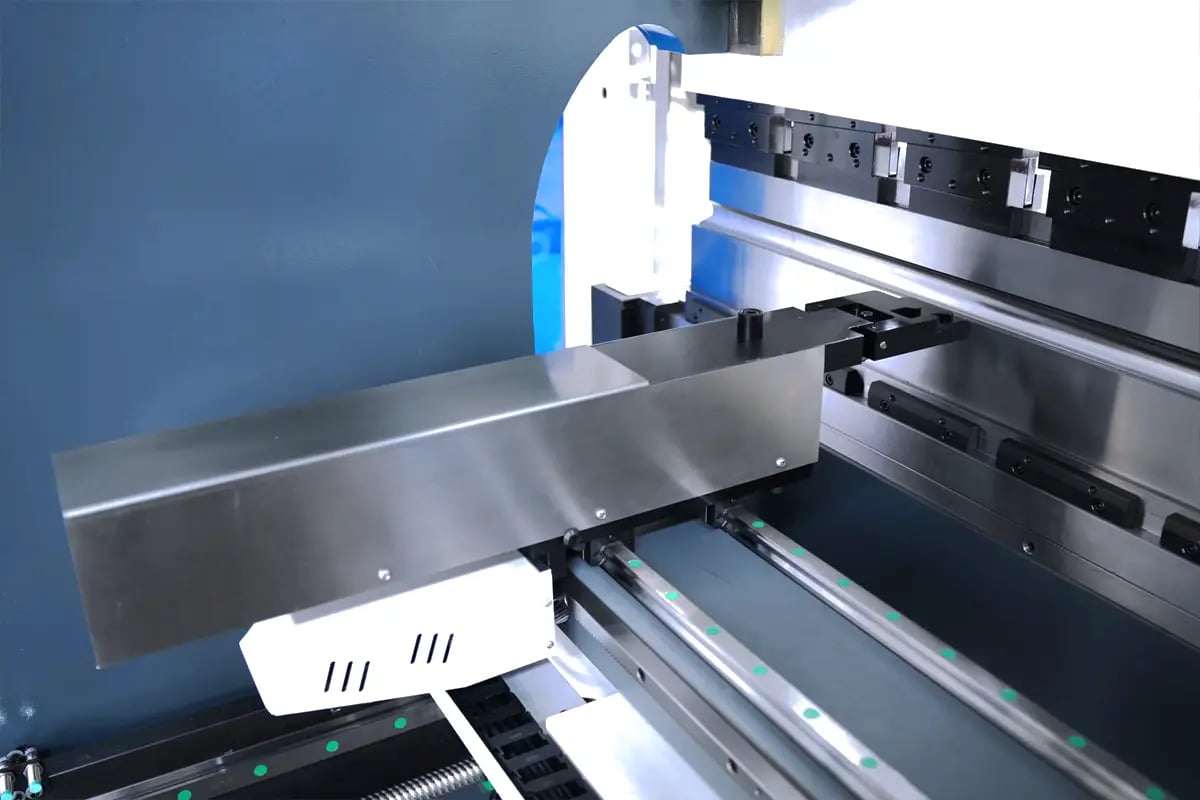

Crowning System

Stress during bending can lead to deformation in the ram and worktable. CNC crowning compensates for ram deformation, significantly enhancing the precision of the press brake. Press brake crowning involves addressing material deflection in sheet metal bending. It employs a curved surface, or crown, on the upper die to counteract deflection, ensuring accurate and uniform bends. When flat material is bent, it often deflects in the center, causing wavy or uneven bends. The press brake's curved upper die distributes bending force evenly, resulting in a uniform bend.

Learn More >>

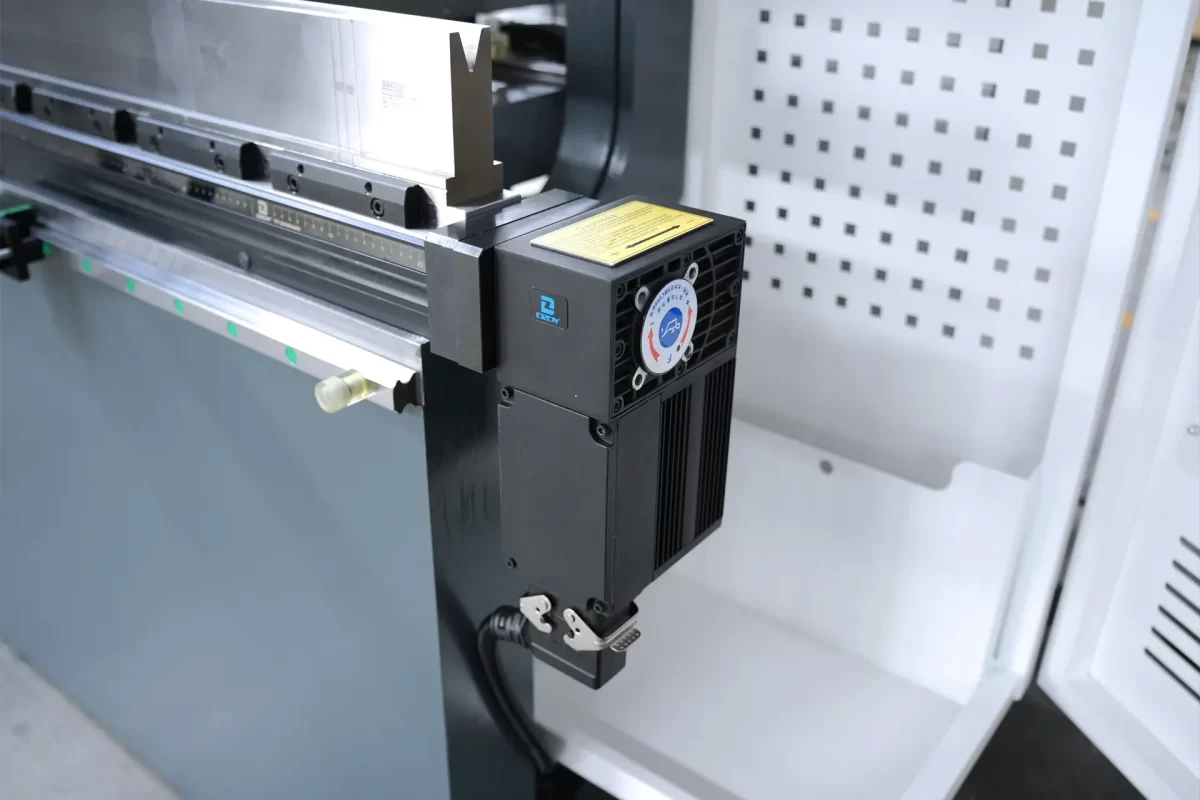

Delem Controller

Delem is a renowned manufacturer of industrial controllers for press brakes, essential machines in metalworking for bending and shaping sheet metal. The Delem controller, an electronic control system, efficiently manages and automates press brake operations. It plays a key role in programming and controlling the bending process, allowing operators to set angles, positions, and depths of bends.

The user-friendly interface facilitates easy input of job specifications, which are executed automatically by the press brake. With advanced features like automatic parameter calculation, angle correction, and simplified programming of complex bending sequences, the Delem controller ensures efficiency. Safety features are also integrated to prevent accidents and protect operators and machines. KRRASS CNC press brakes come equipped with the DELEM high-level controller for enhanced accuracy and efficiency.

| Controller | Picture | Screen | Maximum Axis | Program | Network | Tooling DXF File Import | Product DXF File Import | 3D File Import | Offline Software |

|---|---|---|---|---|---|---|---|---|---|

| DA-53T |  | 10.1“touch screen | 4+1 | Digital+2D (optional) | X | X | X | X | Profile-53TL (activation code) |

| DA-58T |  | 15“touch screen | 4+1 | Digital+2D | Optional | X | X | X | Profile-53TL (activation code) |

| DA-66T |  | 17“touch screen | More than 8+1 | Digital+2D | √ | Optional | Optional | X | Profile-TL (dongle) |

| DA-69T |  | 17“touch screen | More than 8+1 | Digital+2D+3D | √ | √ | √ | √ | Profile-T3D (dongle) |

Learn More >>

Press Brake Video

A press brake video showcases the operation and capabilities of the KRRASS press brake machine—a vital tool in the metalworking industry for bending and shaping sheet metal. These videos highlight the machine's performance, demonstrating features like adjustable bending angles, handling thickness variations, and showcasing the precision with which it bends metal.

Press Brake Blog

The press brake blog centers around topics concerning press brakes, machines pivotal in metal fabrication for bending and shaping metal sheets. Its content spans diverse aspects of press brakes, encompassing operation, maintenance, safety, and technological advancements. Additionally, the blog may showcase industry-related news, reviews, and interviews, along with offering valuable tips, tricks, and tutorials suitable for users of all skill levels. Serving as a valuable resource, the press brake blog caters to professionals in metal fabrication and hobbyists alike who work with press brakes.

2024 Hydraulic Press Brake Selection Guide – How to Quickly Choose a Press Brake

admin

Discover everything you need to know about hydraulic press brakes, including their types, essential molds, safety protection systems, and enhanced functions to improve efficiency and precision in sheet metal processing.

Read more

CNC Press Brake Controller: How To Choose Right One?

krrass

Your CNC press brake is crucial to production in your company, which is why you ...

Read morePress Brake FAQ

What is a press brake?

Unlike the hydromechanical press brake that converted hydraulic energy to mechanical energy using a hydraulic motor fixed to an eccentric shaft, the modern hydraulic press brake employs a hydraulic pump and hydraulic cylinders to move the ram. This design significantly enhances efficiency, enabling increased speed and accuracy.

The modern hydraulic press brake can be categorized into two basic subgroups: up-acting and down-acting (all other types of press brakes are down-acting only). The up-acting style was first designed and utilized by the French. In our perspective, the up-acting press brake stands out as the superior type, not only due to the ram's guidance and arrangement of rollers but also because of its natural antideflection characteristics. Gravity works in favor of the operator, offering a more advantageous working dynamic.

For any mechanical device to have movement, a certain clearance is necessary to allow the mechanism to function freely. On the press brake, a critical clearance exists between the power source and the ram body. While this clearance is optimal when the machine is new or rebuilt, it tends to increase with age and use, leading to excess play in the mechanism. In down-acting presses, this play is located at the bottom when no load is present, shifting to the toe of the connection under load, affecting repeatability and causing variations in bend angles. In contrast, the up-acting press brake consistently maintains this play at the bottom, whether under pressure or not.

Down-acting hydraulic press brakes constitute 90% of all press brakes in use today. Among these, hydraulic press brakes stand out as the most accurate, typically controlled by a CNC or DNC controller (computer numerical control or direct numerical control). These computers, in turn, oversee a proportional valve system, allowing precise control over the ram's downward movement and ensuring accurate bend angle control.

What is a press brake used for?

The press brake machine finds extensive use in steel sheet metal processing, particularly in the following industries:

Decoration Industry:

The CNC press brake machine is essential for bending stainless-steel elevators, steel doors and frames, steel windows, and skirting lines. In some cases, the CNC V-grooving machine is employed after bending to achieve perfect bending angles.

Electric Industry:

The press brake plays a crucial role in electric cabinet production. After the steel sheet is cut by the shearing machine, the press brake is used to bend them into different-sized cabinets using various punch and die types. Segmented tooling, especially for the left and right horns of the punch, is vital for forming the box in the final stage.

Kitchen Industry:

Stainless steel is commonly used in kitchen devices, and the press brake is indispensable for bending them into different shapes before the final product is completed. CNC press brakes with various punch and die options, such as gooseneck punch and 2V die by segments, are commonly used. The machine is also employed for manufacturing HVAC and related products.

Automobile and Ship Industry:

In this sector, large capacity press brakes and CNC press brakes are widely used, demanding higher bending accuracy and efficiency. KRRASS, a press brake manufacturer in China, excels in producing such machines and provides excellent service to customers worldwide.

Aerospace Industry:

The aerospace industry requires high precision, as CNC press brake-produced components are key parts for the final product, and bending tolerance must be within an acceptable range. KRRASS has satisfied customers in this field, known for delivering press brakes that meet stringent requirements.