Press brake controls are essential in metal fabrication, as they facilitate precise, efficient, and safe bending operations, ensuring high-quality outcomes and cost-effective production. Their impact on the modern metalworking industry is profound, making them an invaluable component of the process.

This guide is designed to be a useful resource for anyone in the metal fabrication field, whether you're a newcomer seeking to grasp the fundamentals or a seasoned professional looking to stay informed about the latest developments in press brake controller technology.

What Are Press Brake Contros

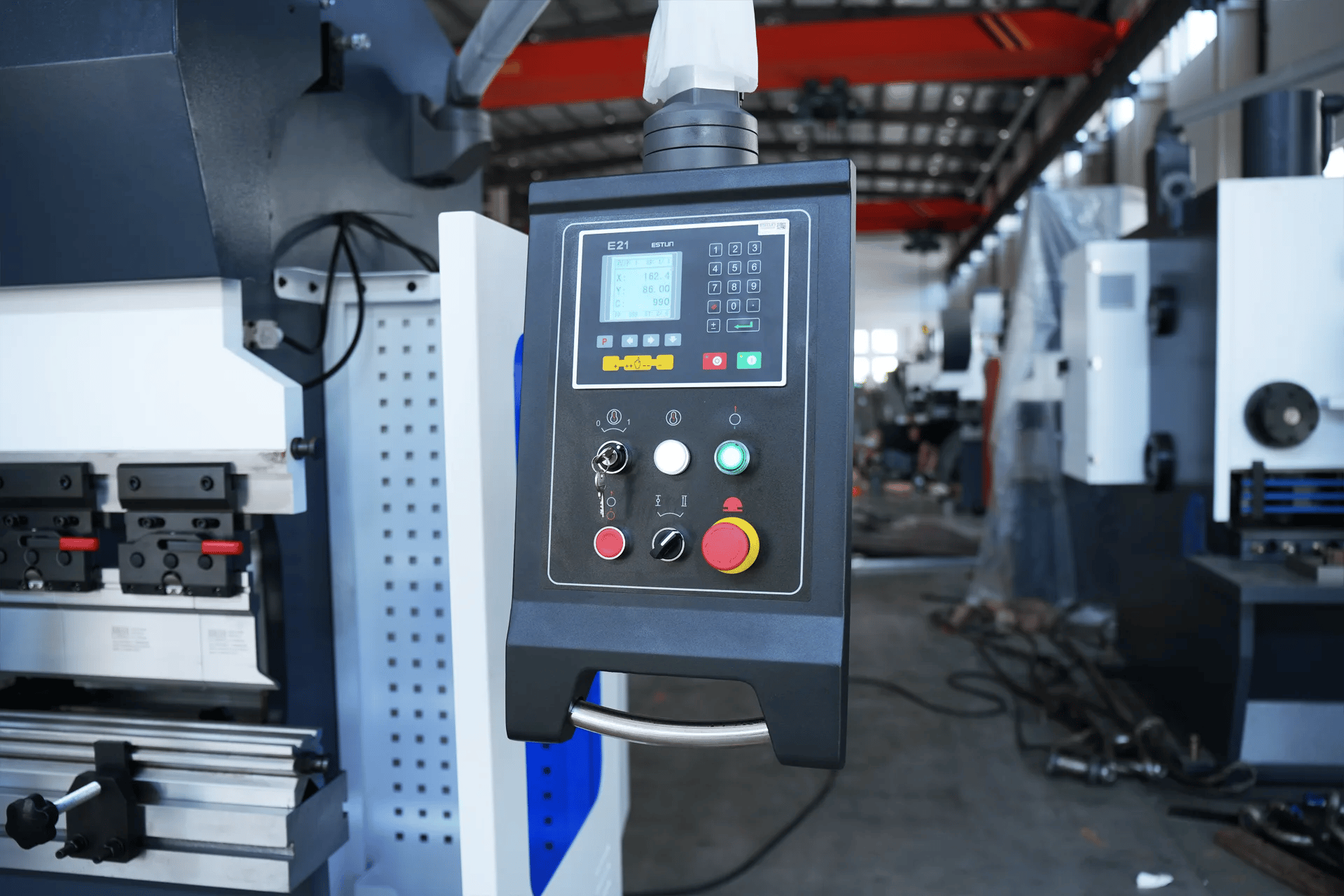

A press brake controller is a specialized device that manages the operation of a press brake machine. The press brake, a robust machine, is designed to bend and shape sheet metal, plates, and other metal materials. Acting as the machine’s central control system, the press brake controller allows operators to shape metal with exceptional precision and consistency, ensuring high levels of accuracy in every operation.

Function of Press Brake Controls

Control Interface:

The control interface of a press brake controller is where the operator interacts with the machine. It typically includes a touchscreen or a user-friendly panel with buttons and a digital display. Through this interface, operators can input bending parameters, such as the desired bend angle, bend length, and tooling information.

Programming Capabilities:

Press brake controllers are equipped with programming capabilities that allow operators to create and store bending programs. These programs define the specific instructions for the bending operation, including the sequence of bends, angles, and positions. Advanced controllers may offer graphical programming interfaces, making it easier to visualize the bending sequence.

Safety Mechanisms:

Safety is of paramount importance in any metal fabrication operation. Press brake controllers are equipped with safety features to protect both the operator and the machine. These safety mechanisms include:

Light Curtains:

These emit an invisible beam of light that, when interrupted, immediately stops the machine’s operation to prevent accidents.

Emergency Stop Button:

A large, easily accessible button that, when pressed, halts all machine movements in case of an emergency.

Interlocks:

These ensure that all safety gates and doors are securely closed before the machine can operate, reducing the risk of accidents.

Real-Time Monitoring:

Many modern press brake controllers provide real-time monitoring and feedback. Operators can observe the bending process, monitor tool wear, and make adjustments as needed to maintain precision and quality.

Accuracy and Repeatability:

The primary function of a press brake controller is to execute bending operations with a high degree of accuracy and repeatability. This is crucial for meeting tight tolerances and producing components that meet quality standards.

Press brake controllers are the central nervous system of press brake machines in metal fabrication. They provide operators with the tools to program, monitor, and control the bending process with precision, efficiency, and safety. Their ability to consistently produce accurate bends is a testament to their importance in the metalworking industry. As technology continues to advance, press brake controllers evolve to meet the demands of a rapidly changing industry, further enhancing their role in shaping the modern world of metal fabrication.

Types of Press Brake Controls

Press brake controllers come in various types, each offering specific features and capabilities to cater to the diverse needs of metal fabrication. Understanding these types is crucial for selecting the right controller for a particular application. Here, we’ll explore two of the common types of press brake controllers:

Manual Controllers:

Manual controllers are the simplest form of press brake control. They provide basic control over the bending operation and are often used on older or smaller press brake machines. In manual controllers, the operator directly adjusts settings such as bend angle, back gauge position, and ram speed using physical controls. While manual controllers are less automated than their digital counterparts, they are cost-effective and can be a good choice for less complex bending tasks.

CNC Controllers:

Computer Numerical Control (CNC) controllers are the modern standard in press brake technology. These controllers offer a high level of automation and precision. CNC press brake controllers are equipped with a computer interface that allows the operator to program complex bending sequences. They offer features such as storing multiple bending programs, tooling management, and real-time monitoring of the bending process. CNC controllers enable precise, repeatable bends and are ideal for high-volume production and applications with strict quality requirements.

How to Choose the Right Press Brake Controls

Press brake controllers are the heart and brain of metal fabrication, responsible for ensuring precise and efficient bending operations. Choosing the right press brake controller is a crucial decision that can significantly impact the quality, productivity, and versatility of your metalworking processes. In this article, we will guide you through the key considerations when selecting the ideal press brake controller for your specific needs.

Determine Your Application Requirements

The first step in choosing the right press brake controller is to clearly define your application requirements. Consider the following factors:

Material Type: Different materials (e.g., steel, aluminum, or stainless steel) may require specific controller features or capabilities.

Material Thickness: Thicker materials may necessitate more powerful controllers.

Part Complexity: Complex parts with multiple bends and tight tolerances may require advanced programming capabilities.

Production Volume: High-volume production may benefit from automated features and efficient tooling management.

Manual vs. CNC Controllers

Decide whether you need a manual or CNC press brake controller:

Manual Controllers: Suitable for simple bending tasks and cost-effective solutions.

CNC Controllers: Ideal for complex bending operations, high precision, and automation

Programming and Interface

Evaluate the ease of programming and the user interface of the controller. Look for the following features:

User-Friendly Interface: An intuitive touchscreen or panel for easy navigation and data entry.

Graphical Programming: Visual aids for creating bending programs, especially helpful for complex parts.

Offline Programming: The ability to program bending sequences offline and transfer them to the controller.

Tooling Compatibility

Ensure that the press brake controller is compatible with the tooling you plan to use. Check for features such as tooling libraries and the ability to manage and optimize tool setups.

Safety Features

Safety is paramount in metal fabrication. Consider the following safety features:

Light Curtains: Infrared safety barriers that stop the machine if an object or operator enters the danger zone.

Emergency Stop Button: A large, easily accessible button to halt all machine movements in case of an emergency.

Interlocks: Safety measures that ensure all safety gates and doors are closed before operation.

Brands and Models

Research reputable brands and models of press brake controllers. Popular brands like Delem, ESA, and others offer a wide range of options with various features and capabilities. Read reviews and seek recommendations from industry peers.

Budget Considerations

Determine your budget for the press brake controller. While advanced controllers offer numerous features, it’s essential to strike a balance between cost and functionality that aligns with your specific needs.

Operator Skill Level

Consider the skill level of your operators. User-friendly controllers with clear interfaces are beneficial, especially if you have operators with varying levels of expertise.

Future-Proofing

Think about the long-term. Select a press brake controller that can adapt to your evolving needs and changing technology. Controllers with software updates and expandable features can be a wise investment.

Common Brands of Press Brake Controls

While many manufacturers produce these controllers, certain brands have earned recognition for their innovation, reliability, and performance. In this introduction, we will take a closer look at various prominent brands of press brake controllers.

Delem:

Delem is a well-established and respected brand in the world of press brake controllers. Known for their advanced CNC controllers, Delem offers a range of features that cater to the needs of the metalworking industry. Their controllers are recognized for their precision and reliability, making them a preferred choice for many metal fabrication professionals. Delem controllers often feature user-friendly interfaces and compatibility with various press brake models, allowing for seamless integration into existing workflows.

ESA:

ESA, or European Systems Automation, is another reputable brand that manufactures high-quality press brake controllers. ESA controllers are known for their innovation and flexibility. They offer a wide array of advanced features, including angle correction, collision avoidance, and network connectivity. These controllers are often chosen by manufacturers who require sophisticated capabilities and efficient production processes.

Cybelec:

Cybelec is a Swiss brand with a strong presence in the press brake controller market. Their controllers are widely recognized for their precision and adaptability. Cybelec offers solutions for both standard and complex bending applications. Their controllers often feature user-friendly interfaces and powerful programming capabilities, making them an excellent choice for a variety of metalworking needs.

Amada:

Amada, a renowned name in the manufacturing industry, also produces press brake controllers. Their controllers are known for their compatibility with Amada press brake machines, ensuring seamless integration and optimized performance. Amada controllers are engineered to provide accurate and efficient bending operations, reflecting the brand’s commitment to quality and innovation.

LVD:

LVD is a global manufacturer of press brake controllers, among other metalworking equipment. LVD controllers are designed to enhance the precision and productivity of press brake machines. They often come equipped with advanced features for programming, monitoring, and safety. LVD controllers are well-regarded for their contribution to the efficiency of metal fabrication processes.

Custom Solutions:

In addition to these established brands, some metal fabrication operations may require specialized or custom press brake controllers. These solutions are tailored to the unique needs of the application and may involve collaboration with control system providers or machine manufacturers to develop bespoke solutions.

Conclusion

These are just a few of the prominent brands in the press brake controller market. Each of these brands offers a distinct set of features, capabilities, and innovations to meet the diverse requirements of the metal fabrication industry. Choosing the right press brake controller brand depends on factors such as the specific needs of your application, the compatibility with your press brake machine, and the level of precision and automation you seek. Whether you opt for a renowned brand like Delem, ESA, or Cybelec, or explore custom solutions, the ultimate goal is to enhance the accuracy, efficiency, and productivity of your metalworking processes.

NC VS CNC Control System: Comparison

In the world of metal fabrication, choosing the right press brake machine controls is paramount for precision and efficiency. The numerical control system of the press brake is a system that controls the machine's procedures through a series of programming.

The control system of the press brake is divided into NC and CNC controllers. Both CNC and NC controller are used to ensure the positioning accuracy of the press brake tooling and backgauge. Their main difference lies in whether the program allows modification.

The numerical control system cannot modify the program, while the CNC system can modify or edit the program. The CNC system is an advanced version of the NC system that greatly improves the accuracy and efficiency of the bending operation.

| Feature | NC (Numerical Control) | CNC (Computer Numerical Control) |

| Full Form | Numerical Control | Computer Numerical Control |

| Input Method | Punch tapes and punch cards | Keyboards and digital input |

| Program Modification | Difficult, requires re-punching cards | Easy, can be modified directly on the computer |

| Memory Storage | No memory storage for programs | Memory available to store and reuse programs |

| Cost | Less expensive | More expensive |

| Maintenance Cost | Lower | Higher |

| Operator Skill Requirement | Requires highly skilled operators | Requires less skilled operators |

| Flexibility | Less flexible | More flexible |

| Accuracy | Lower accuracy | Higher accuracy |

| Execution Time | More time-consuming | Less time-consuming |

| Continuous Operation | Cannot run continuously | Can run continuously for 24 hours |

| Automation Level | Lower automation | Higher automation |

| Applicable Scenarios | Simple operations like drilling, boring, and milling | Complex operations like milling, turning, grinding, and drilling |

| Computational Capability | Limited | Advanced, with feedback systems for greater accuracy |

| Production Efficiency | Lower | Higher, suitable for mass production |

| Human Intervention | Requires more manual intervention | Minimal manual intervention needed |

| Program Storage | Programs cannot be stored | Programs can be stored and reused |

| Operational Feedback | Open-loop system, no feedback | Closed-loop system, provides feedback for accuracy |

The CNC system is also user-friendly and can enhance work efficiency. It contains various programming functions that can store a large number of complex bending steps, allowing for the production of large quantities of complex workpieces faster. A good control system can optimize procedures and improve production efficiency.

However, do you know which press brake controller is the best choice? This article will introduce how to select the right press brake controller. Before starting, let's watch the video first.

Brands of CNC Control Systems: Comparison

1. Delem CNC Control Systems

Delem, founded in the Netherlands in 1978, is a leading enterprise focusing on the CNC control field of sheet metal bending manufacturing. Delem's press brake control systems include DA-Retrofit solutions, DA-40 series, DA-50 series, and DA-60 series.

The DA-66T, 69T, 53T, 58T, 41T, and 42T of Delem CNC control systems are touchscreen versions. While DA-66W and 65R CNC control systems are button versions.

(1) Touch Screen Version

Delem has a variety of touchscreen versions of the CNC controller.

DA-40 series

The controller of this series is specially used for traditional torsion shaft press brakes. The system is able to control the back gauge(X&R), and beam(Y).

The bright LCD screen can be used for programming parameters including angle, tool, and material. The DA-42 also has the functions of crowning control and pressure control.

DA-50 series

A-58T is suitable for the electro-hydraulic synchronous press brake. DA-58T provides 2D touch graphic programming to calculate the bending process and collision detection automatically. The positions of all axes are calculated automatically.

The bending process is simulated by the real scale machine and toolings. DA-58T also can be used for tandem operation. DA-53T is able to control Y1, Y2, and two auxiliary axes.

DA-60 series

The DA-60 series offers 2D and 3D full touch screen graphics programming. The DA-69T and DA-66T are suitable for bending procedures requiring high accuracy. The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. The system is modular, the program is expanded, and the operation is more flexible.

(2) Button Version

Delem's two common button version controllers are the DA-66W and the DA-65R. These two systems provide 2D graphic programming and 3D graphic display functions. They also offer a multi-machine linkage function, and the touch screen is an optional configuration.

2. ESA CNC Control System

Founded in Italy in 1962, Automation is a world-leading expert in the field of integrated CNC systems. By 2022, ESA's products will mainly include the 600 and 800 series. Commonly used are the S660, S640, S630, S830, S840, S850, etc.

(1) S600 Series

The S600 series are all touch screens. They can control a minimum of 3 axes and a maximum of 128 axes. The PLC and HMI can be reprogrammed to meet customized requirements. They can adapt to a variety of bending machines, including hydraulic press brakes, synchronous hydraulic press brakes, electric press brakes, and tandem press brakes, etc.

(2) S800 Series

The S800 series is a new product line launched by the company in 2020. The innovation of the S800 series is mainly reflected in intelligent modularization, complete digitalization, and wireless network connection. The screen is 100% full touch, and graphical tools can develop complex 3D interfaces.

3. Cybelec CNC Control System

Cybelec, founded in Switzerland in 1970, is a world-famous manufacturer of computer numerical control software for metal forming. Cybelec's CNC system includes button versions: CT8P, CT8PS, CT8PS, CT15P, and the touch screen version: VisiTouch series. The following is a video of our company’s experience using the Cybelec VT19 controller:

The Cybtouch series is equipped with the Cybtouch tool, which can be used for wireless transmission between PC and system. Modern streamlined glass surface touch screens can be used with gloves.

The touch screen provides 2D or 3D graphics programming, which can be programmed directly. Automatic calculation of bending sequence, angle measurement, and collision detection. It can control multi-axis movement and can be used for tandem press brakes

Press Brake Controller Comparison

| Feature/Brand | Delem DA-66T | ESA 630 | Cybelec VisiTouch 19 |

| Display | 17" high-resolution color TFT touch screen | 10" color touch screen | 19" modern streamlined glass surface touch screen |

| Programming Mode | 2D graphical programming, automatic bend sequence calculation, collision detection | 2D graphical editor and display | 2D graphical profile drawing, automatic bend sequence calculation |

| Memory Capacity | 1 GB | 128 MB silicon disk | 32 GB CFAST memory card SATA |

| Axes Supported | Up to 8+1 axes | Up to 5 axes | Multiple axes, including complex bending aids and slave axes |

| Operating System | Embedded real-time Windows | Not specified | Windows 10 |

| User Interface | Intuitive touch navigation, optimized ergonomics | User-friendly touch screen interface | User-friendly HMI, intuitive programming, dedicated set-up wizards |

| Offline Programming | Profile-TL offline software | One offline software license included | Internal backup and restore functions |

| Safety Features | Emergency stop switch, sensor bending & correction interface | Not specified | DSP-TX laser safety system, Y1/Y2 auto compensation |

| Price | High | Low | Medium |

| Ease of Use | High, intuitive user interface | Medium, suitable for simple to medium complexity operations | High, user-friendly interface, quick setup |

| Compatibility | Delem Modusys compatibility, USB, peripheral interfacing | Suitable for various press brakes including conventional, synchro, hybrid, electric, tandem | Compatible with DXF flat pattern and 3D format files |

| Additional Features | Full 3D machine setup, multiple tool stations, highly effective control algorithms | Advanced graphic programming, sophisticated algorithms, clear and ergonomic HMI | Full 3D visualization and simulation, automatic solutions for complex parts |

1. ESA Control Systems

Advantages:

- Versatility: ESA's S600 and S800 series feature touch screen controls and can manage configurations from 3 to 128 axes.

- Programmability: PLC and HMI can be reprogrammed to meet custom requirements.

- Wide Applicability: Suitable for various types of press brakes, including hydraulic, synchronized hydraulic, electric, and tandem press brakes.

- Rapid Upgrades: ESA products are frequently updated to keep pace with technological advancements.

Disadvantages:

- Complexity: Due to its multifunctionality, it may require more time for learning and adaptation.

2. Cybelec Control Systems

Advantages:

- Excellent Quality: Cybelec products are renowned for their superior quality, providing high-precision bending control.

- High Reliability: Performs excellently over long-term use with low failure rates.

Disadvantages:

- Complex Operation: Compared to other brands, Cybelec's interface may be more complex, requiring more training and adaptation time.

3. Delem Control Systems

Advantages:

- Ease of Use: Delem products are user-friendly and easy to operate, suitable for quick onboarding.

- Variety of Options: Offers a range of models, including touch screen versions (e.g., DA-66T, 69T, 53T, 58T, 41T, 42T) and button versions (e.g., DA-66W, 65R), catering to different needs.

- Efficient Programming: Systems like the DA-58T provide 2D touch graphical programming, automatic bending process calculation, and collision detection.

Disadvantages:

- Higher Cost: Delem products are relatively expensive, which may not be suitable for budget-conscious users.

4. Recommendations

When choosing a press brake controller, consider your specific needs and budget:

- Limited Budget and Quick Onboarding: Delem control systems are recommended for their ease of use, though their higher cost should be considered.

- High Quality and Precision: Cybelec is a great choice, despite its more complex operation, its superior quality and reliability are worth the investment.

- Multifunctionality and Customization: ESA control systems are the best choice, especially for scenarios requiring multi-axis control and customization.

Latest Advancements In Press Brake Controls Technology

The field of metal fabrication is continually evolving, and press brake controller technology is no exception. Recent advancements in press brake controllers have brought about significant improvements in precision, efficiency, automation, and user-friendliness. Here’s an overview of some of the latest innovations and trends in press brake controller technology:

Integration with CAD/CAM Software:

One of the most notable advancements in press brake controller technology is the seamless integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows for direct importation of part designs into the press brake controller, reducing the need for manual data entry and minimizing the risk of errors. Operators can now quickly and accurately program complex bending sequences from CAD files, increasing efficiency and precision.

Offline Programming and Simulation:

Modern press brake controllers often offer offline programming and simulation capabilities. This technology allows operators to create and test bending programs without interrupting the actual production process. Virtual simulations help identify and address potential issues, ensuring that the bending process is optimized before it begins. This reduces setup times and minimizes scrap, ultimately leading to cost savings.

3D Graphics and Visualization:

Some of the latest press brake controllers are equipped with advanced 3D graphics and visualization features. These interfaces provide operators with a comprehensive view of the bending process, allowing them to inspect the part, tooling, and machine setup in a virtual environment. This aids in quick and accurate setup, especially for complex parts with multiple bends.

AI-Assisted Bending:

Artificial intelligence (AI) and machine learning are finding their way into press brake controller technology. AI algorithms can analyze past bending data to optimize future bending processes. This technology can predict potential issues and suggest adjustments, leading to improved quality and efficiency.

IoT Connectivity:

The Internet of Things (IoT) is making its mark in the metal fabrication industry. Press brake controllers with IoT connectivity can transmit real-time data about machine performance, tool wear, and production metrics to a centralized system. This enables proactive maintenance, data-driven decision-making, and remote monitoring of the production process.

User-Friendly Interfaces:

The latest press brake controllers prioritize user-friendliness. Intuitive touchscreen interfaces, graphical programming, and step-by-step wizards make it easier for operators with varying skill levels to set up and run bending operations efficiently. Such interfaces reduce the learning curve and minimize the risk of errors.

Safety Innovations:

Safety remains a top priority in press brake controller technology. Advanced controllers are equipped with improved safety features, such as enhanced light curtains, multi-zone safety systems, and better integration with emergency stop functions. These measures ensure that operators and equipment are protected during operation.

Energy Efficiency:

Some press brake controllers now focus on energy efficiency. They can optimize machine movements, reducing energy consumption and environmental impact. Energy-efficient controllers not only save on operational costs but also contribute to sustainable manufacturing practices.

In conclusion, the latest advancements in press brake controller technology have revolutionized the metal fabrication industry. These innovations focus on enhancing precision, efficiency, and user-friendliness, while also incorporating safety, connectivity, and sustainability features. As the industry continues to evolve, press brake controllers will likely play an even more critical role in shaping the future of metalworking.

Conclusion

Modern press brake machines are equipped with advanced press brake controls, and different brands and models of these controllers may offer distinct advantages. Before choosing an advanced press brake control system, it is essential to fully understand its features and the reputation of the brand, then select the most suitable controller based on your budget.

When selecting a controller for a press brake, key factors to consider include functionality, stability, ease of use, and safety. User-friendly press brake controls can enhance productivity, reduce setup time, and improve overall machine performance. High-quality controllers are designed to ensure accurate bending and reliable results.

In this article, I explore three advanced press brake control brands that offer the best user experience. KRRASS, for instance, continually updates its product range, offering cutting-edge features and improvements. While KRRASS press brake controls are known for their ease of use, they may come at a higher price point. However, their superior quality justifies the investment. Upgrading to a state-of-the-art press brake CNC controller can boost machine performance and reduce overall production costs.