Understanding the crucial role of correct tonnage selection in press brake machines is paramount for ensuring optimal product quality. Failure to select the appropriate tonnage can lead to various quality issues such as material deformation or cracks, ultimately affecting customer satisfaction. To aid in your comprehension of press brake tonnage, including how to calculate it effectively, we'll delve into essential aspects. Today, we'll explore the significance of utilizing a press brake tonnage chart, providing insights to help you make informed decisions and elevate product quality.

Table of Contents

Introduction

What is A Press Brake

Press brakes are pivotal machines in the sheet metal fabrication industry, utilized for bending and shaping metal sheets with precision. They play a fundamental role in transforming flat sheets of metal into various components used in industries ranging from automotive to construction.

Types of Press Brake

Mechanical Press Brakes: These are driven by a flywheel and use an eccentric mechanism to move the ram, suitable for high-speed bending operations.

Hydraulic Press Brakes: These utilize hydraulic cylinders to move the ram and apply force to the workpiece. They offer precise control of the bending process and are capable of handling high tonnage requirements.

Pneumatic Press Brakes: These use air pressure to move the ram and are typically used for lighter gauge materials or smaller production requirements.

Servo-Electric Press Brakes: These employ a servo-motor to control the ram’s motion, offering high precision and energy efficiency. They are ideal for applications requiring low to medium bending force.

CNC Press Brakes: Although not a type on their own, CNC technology can be integrated into hydraulic, pneumatic, or servo-electric press brakes to automate and control the bending process, enhancing accuracy and repeatability.

Importance of Press BrakeTonnage Charts

Precision: Press Brake Tonnage charts assist professionals in determining the precise amount of force needed for bending operations, ensuring accurate results.

Efficiency: By referencing tonnage charts, fabricators can streamline their workflow and minimize material waste by selecting the appropriate press brake settings.

Cost-Effectiveness: Accurate use of tonnage charts helps in optimizing resources, leading to cost savings in terms of material usage and machine operation.

Safety: Proper utilization of tonnage charts ensures that the press brake operates within safe parameters, reducing the risk of accidents and equipment damage.

Basic Concepts

Explanation of Press Brake Tonnage Charts

Press brake Tonnage Charts are graphical representations that provide essential data regarding the amount of force required to bend a specific material of a particular thickness and length. These charts typically include various parameters such as material type, thickness, bend length, and bend angle.

By referencing these charts, sheet metal fabrication professionals can accurately determine the tonnage needed to achieve precise bends, ensuring the quality and integrity of the finished components.

Functions and Applications of Press Brake Tonnage Charts

Determining Bending Force: Tonnage charts help in determining the amount of force needed to bend a given material accurately. This information is crucial for selecting the appropriate press brake machine and tooling setup.

Optimizing Bending Process: By referencing tonnage charts, fabricators can optimize the bending process, minimizing trial and error and reducing material waste. This leads to increased efficiency and cost-effectiveness in sheet metal fabrication operations.

Ensuring Quality and Accuracy: Tonnage charts play a vital role in ensuring the quality and accuracy of the bending process. By selecting the correct tonnage based on the material properties and dimensions, professionals can achieve precise bends, meeting the desired specifications and tolerances.

Safety Considerations: Proper utilization of tonnage charts helps in ensuring that the press brake operates within safe parameters. Overloading the machine can lead to equipment damage or accidents, highlighting the importance of referencing tonnage charts for safe operation.

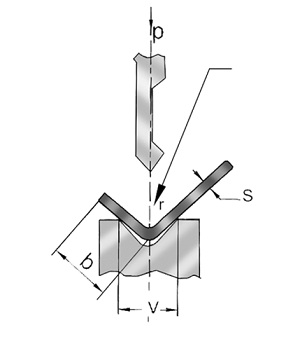

Components of Press Brake Tonnage Charts

Press Brake Tonnage Charts typically consist of the following components:

Material Type: Different materials exhibit varying levels of resistance to bending, necessitating different amounts of force. Common materials include steel, aluminum, and stainless steel.

Material Thickness: The thickness of the metal sheet being bent directly influences the amount of force required. Thicker materials typically require higher tonnage.

Bend Length: The length of the bend or the distance between the bending points affects the required tonnage. Longer bends may require higher tonnage compared to shorter bends.

Bend Angle: The angle at which the material is bent also impacts the required tonnage. Sharper angles may require higher tonnage to achieve the desired bend.

Press Brake Tonnage Charts for Bending Process Design

How to Select Press Brake Tonnage Based on Press Brake Tonnage Charts

Match Material Characteristics:

Ensure that the material type and thickness match the specifications provided on the tonnage chart. Different materials require different amounts of force for bending, so it's crucial to select the appropriate category on the chart.

Consider Bend Specifications:

Take into account the specific requirements of the bend, including the bend angle and length. These specifications will influence the amount of force needed for the bending process and help determine the appropriate tonnage.

Refer to the Tonnage Chart:

Consult the press brake tonnage chart to determine the required tonnage based on the material properties and bend specifications. Locate the corresponding values for bend length, angle, and material thickness on the chart to identify the appropriate tonnage range.

Select Compatible Tooling:

Choose press brake tooling that is compatible with the selected tonnage and bend specifications. The tooling should be capable of achieving the desired bend angle and length without exceeding the specified tonnage limits.

Verify and Adjust as Needed:

Before initiating the bending process, verify that the selected tonnage and tooling setup align with the specifications provided by the tonnage chart. Make any necessary adjustments to ensure accuracy and precision in the bending operation, taking into account factors such as material variations and bend complexity.

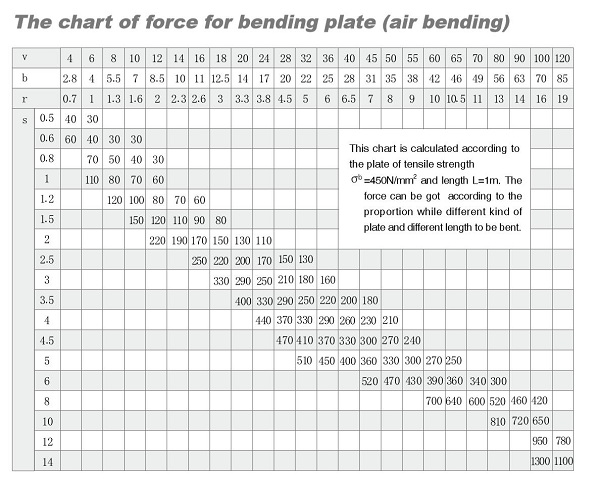

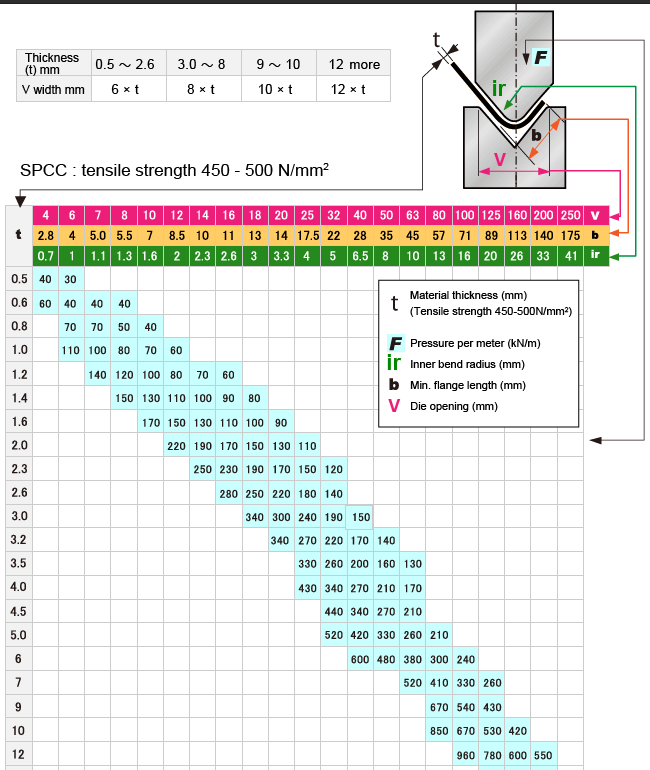

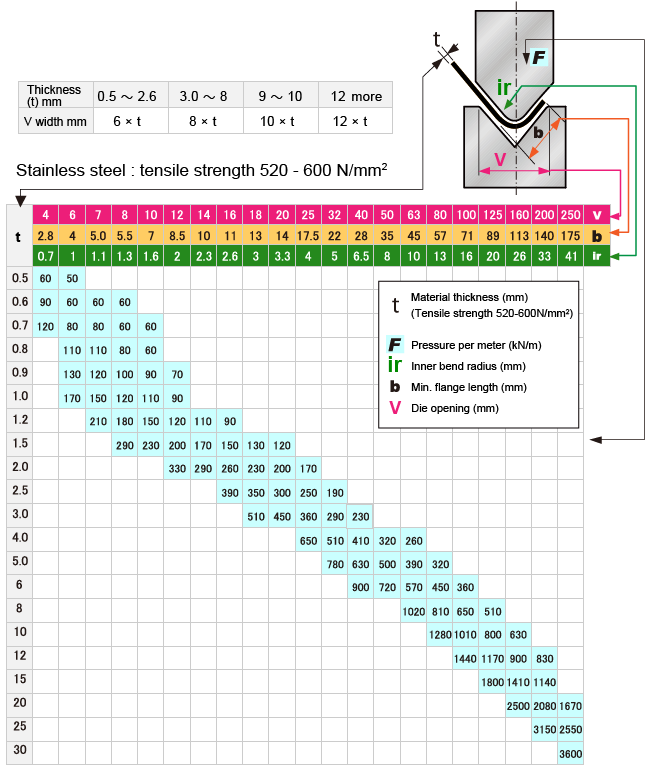

Air Bend Force Chart

An Air Bend Force Chart, or Force Chart breaks down a number of key components of sheet metal bending in an easy to reference format. Being able to read a bend force chart is crucial for any Brake Press operator and sheet metal engineer.

The gauge, inside radius, die opening, and minimum flange length are all interconnected through different equations and relationships, the Air Bend Force Chart organizes these variables and points the way towards the ideal setup.

Note: The value in the table is the pressure required to bend the sheet when the length is 1 meter.

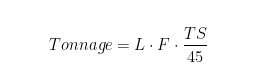

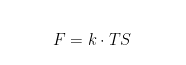

Calculating Required Tonnage For Bending

Once you understand how to use a bend force chart it is easy to calculate the necessary tonnage for any bend operation:

- Calculate your desired V Opening based on the thickness of the sheet metal you’re bending. Round up to the nearest V Opening on the chart to match to your tooling.

- Calculate the ratio of the tensile strength of your material to the standard steel. (.3% Carbon, 45 kg/mm²). We do this because most Air Bend Force Charts are based off of standard steel.

- Multiply the Work Piece Length (L) by the Tonnage Per Foot (F) from the standard force chart by the ratio of the material’s Tensile Strength (TS) to the tensile strength of mild steel.

Tensile Strength (TS)

The tensile strength is a property of the metal and is based off of how much force is required to cause the material to fail or break. The required tonnage is directly related to the tensile strength of the material. As we’ll show below the tensile strength serves as a convenient way of converting a bend force chart from one material to another.

Tensile Strengths of Different Materials

| Material | Soft (kg/mm^2) | Hard (kg/mm^2) |

| Lead | 2.5 - 4 | - |

| Tin | 45387 | - |

| Aluminum | 9.3 | 171 |

| Aluminum Alloy Type 4 | 23 | 48 |

| Duralumin | 26 | 48 |

| Zinc | 15 | 25 |

| Copper | 22-28 | 30-40 |

| Brass (70:30) | 33 | 53 |

| Brass (60:40) | 38 | 49 |

| Phosphor Bronze / Bronze | 40-50 | 50-75 |

| Nickel Silver | 35-45 | 55-70 |

| Cold Rolled Iron | 32-38 | - |

| Steel .1% Carbon | 32 | 40 |

| Steel .2% Carbon | 40 | 50 |

| Steel .3% Carbon | 45 | 60 |

| Steel .4% Carbon | 56 | 72 |

| Steel .6% Carbon | 72 | 90 |

| Steel .8% Carbon | 90 | 110 |

| Steel 1.0% Carbon | 100 | 130 |

| Silicon Steel | 55 | 65 |

| Stainless Steel | 65-70 | - |

| Nickel | 44-50 | 57-63 |

How to Read Press Brake Tonnage Chart

The Press Brake Tonnage Chart can be useful when the material thickness and iR (product inner radius) are known.

Required tonnage to bend 1mm long material ( F )

Die's V width ( V-opening ) mm ( V )

Minimum flange length to bend mm (b)

Common Issues and Solutions in Tonnage Chart Usage

Material Variations

Issue: Material variations, such as differences in hardness or composition within the same material type, can lead to discrepancies between predicted and actual bending forces.

Solution:

Material Testing: Conduct thorough material testing to determine its mechanical properties, including hardness, yield strength, and elasticity. Use this data to adjust tonnage calculations accordingly.

Adjust Tonnage Settings: Increase the safety margin when selecting tonnage from the chart to accommodate potential material variations. This ensures the press brake can handle unexpected changes in material properties without compromising the bending process.

Regular Calibration: Ensure the press brake is regularly calibrated to maintain accuracy in tonnage calculations and bending force predictions.

Complex Bend Shapes

Issue: Bending operations involving complex shapes or multiple bends may pose challenges in accurately predicting required tonnages.

Solution:

Break Down Bends: Break down complex bending operations into smaller, manageable segments. Analyze each segment individually and calculate the required tonnage based on specific bend parameters.

Iterative Approach: Start with lower tonnage settings and gradually increase as needed. This allows for fine-tuning and adjustment as the bending process progresses, ensuring optimal results.

Simulation Software: Utilize simulation software that accurately predicts bending forces for complex shapes. These tools simulate the bending process virtually, allowing fabricators to optimize tonnage settings before actual production.

Consult Experts: Seek advice from experienced professionals or engineers specializing in sheet metal fabrication for guidance on handling complex bend shapes and selecting appropriate tonnages.

Material Thickness Variations

Issue: Variations in material thickness across the sheet can result in uneven bending or overloading of the press brake.

Solution:

Thickness Measurement: Measure material thickness at multiple points across the sheet to identify variations. Use the maximum thickness value when referencing the tonnage chart to ensure sufficient capacity for all areas of the bend.

Selective Bending: Adjust the bending sequence to account for thickness variations if possible. Prioritize bends in areas with consistent thickness to minimize the impact of variations on the overall bending process.

Implement Quality Control: Implement stringent quality control measures to ensure material thickness remains within acceptable tolerances. Regular inspections and checks during the manufacturing process can help identify and address thickness variations early on.

Operator Error

Issue: Inaccurate data input or misinterpretation of tonnage charts by operators can lead to improper selection of tonnage settings.

Solution:

Training and Education: Provide comprehensive training to operators on how to properly interpret and utilize tonnage charts. Emphasize the importance of accurate data input and the potential consequences of operator error.

Double-Check: Implement procedures for double-checking tonnage calculations and settings before initiating bending operations. Encourage operators to verify selected tonnage against specifications provided by the tonnage chart to ensure accuracy.

Documentation: Maintain detailed documentation of tonnage calculations and settings for each bending operation. This allows for easy reference and review, helping to identify and address any discrepancies or errors. Regular training refreshers and skill assessments can also help mitigate operator errors over time.

How To Calculate Press Brake Tonnage

Relationship Between Bending Pressure and Press Brake Tonnage

On the pressure gauge, the unit of pressure is MPa. 1Pa=1N/m2, 1MPa=1000000Pa, 1m2=1000000mm2. The kilogram force is the unit of force: 1 kg force = 9.8 Newton. They are two different physical quantities. But they have certain relationship: to produce a pressure of “1 MPa,” it requires about 10 kg of force on an area of one square centimeter. [1N=1kg·m/s²]

When selecting a bending machine, the customer usually chooses the machine by tonnage. To be precise, 980KN pressure is 100 tons force. In machine selection, we estimate roughly that 1000KN pressure is about 100 tons force.

Formula for Press Brake Tonnage Calculation

The calculation formula of pressure: P=650S2·L/V

Important Parameters in bending process

P = Nominal pressure (KN)

S = plate thickness (mm)

L = plate length (m)

V = notch width (mm)

As a rule, the notch width is 8-10 times the thickness of the plate.

Tonnage Calculator

Recommended V opening of the bottom die

| Material thickness S | 0.5-2.5mm | 3-8mm | 9-10mm | >12mm |

| Bottom die V opening | 6×S | 8×S (General) | 10×S | 12×S |

Bending inner radius from V-die opening

| Material | V |

| Mild steel | 1/6 × V |

| Stainless | 1/5 × V |

| Aluminium | 1/8 × V |

Required tonnage for other metals

| Soft brass | Tonnage × 0.5 |

| Soft aluminium | Tonnage × 0.5 |

| Stainless steel | Tonnage × 1.5 |

| High strength steel | Tonnage ×2.75 |

Hemming tonnage mild steel

| t,mm | Tear,t/m | Full hem |

| 0.6 | 9 | 23 |

| 1 | 15 | 40 |

| 1.5 | 22 | 63 |

| 2 | 30 | 80 |

| 2.5 | 55 | 90 |

| 3 | 77 | 100 |

Cases Study

Case1

When plate length=4000mm, s=5mm, we calculate v=45mm (5×9=45). We check the chart and find the unit bending pressure = 360kN/m. Because plate length is 4m, we know the total tonnage = 360kN x 4 = 1440kN = 144Tons

The data in this table are based on materials with tensile strength = 450N/mm².

The table above is for carbon steel plate, so calculating press brake tonnage for different material plate need to times different material coefficient.

The approximate calculation coefficient of bending pressure is as follows:

Bronze (soft): 0.5

Stainless steel: 1.5

Aluminum (soft): 0.5

Chrome molybdenum steel: 2

Case2

A factory needs to buy a CNC hydraulic press brake to bend stainless steel plate. Plate length is 3meter, thickness is 6mm.

By checking the bending force chart, we know the unit pressure needs 390kN, and the total tonnage is 1170kN (117tons). Because the stainless steel coefficient is 1.5, the factory needs to buy press brake with at least 175.5 tons.

Calculate by the formula: P=650×62×3/ (10×6)=117kN. If it is stainless steel, tonnage is 117.5×1.5=175.5ton.

According to the bending requirements and production conditions, customers can choose the suitable bending equipment. However, press brake tonnage using also depends on press brake lower die in specific cases. Using wider opening of lower die, the press brake requires smaller tonnage. People still need to consult tonnage with press brake factory when they buy press brake with customize upper punch and lower die.

Overestimate Tonnage - Consequences &Methods

Using excessive tonnage during the press brake operation can lead to several risks and complications. It is important to understand these risks to maintain the quality of the workpiece and the integrity of the press brake machine.

The Risks of Using Too Much Tonnage

Damage to the Press Brake:

Overestimating the tonnage can exert undue stress on the press brake components, potentially leading to premature wear or even catastrophic failure of the machine.

Tooling Damage:

Excessive force can damage the punch and die, resulting in costly repairs or replacements and downtime for the machine.

Workpiece Damage:

Applying too much force can cause defects in the metal, such as cracking, warping, or exceeding the desired bend angle, which can render the workpiece unusable.

Reduced Accuracy:

Over-tonnage can lead to springback variations and inconsistencies in the bend angle, compromising the precision of the bending process.

Safety Hazards:

Operating a machine beyond its intended capacity can pose safety risks to the operator and other personnel in the vicinity.

Tips for Avoiding Overestimation

Use Accurate Material Data:

Ensure that the tensile strength and material thickness are accurately measured and accounted for in the tonnage calculations.

Select the Appropriate Die Width:

Choose a die opening that is suitable for the material thickness and type, as this can significantly impact the tonnage requirement.

Consult Material and Equipment Charts:

Manufacturers often provide charts that relate material properties to the required tonnage for specific bend lengths and angles. Utilize these charts for more accurate estimations.

Employ a Tonnage Calculator:

Use a reliable press brake tonnage calculator that factors in all the variables, including material type, thickness, bend length, and die width.

Consider the Bend Radius: Account for the desired bend radius in your calculations, as this can affect the amount of tonnage required.

Perform Test Bends:

Conduct test bends on scrap material to determine the actual tonnage needed for a particular job, which can help refine your estimates.

Use CNC Controls When Available:

For CNC press brakes, take advantage of the control system’s ability to calculate and adjust tonnage automatically based on programmed parameters.

Stay Within Machine Limits:

Always refer to the press brake’s specifications to ensure that the tonnage does not exceed the machine’s maximum capacity. Operating within the press brake’s limits is crucial for the longevity of the equipment and the safety of operations.

Train Operators:

Properly train press brake operators to understand the importance of accurate tonnage calculation and the risks associated with overestimation. An informed operator is more likely to make precise adjustments and recognize when tonnage settings may be too high.

Regular Maintenance:

Keep the press brake and tooling in good working condition. Regular maintenance can help identify potential issues that may affect the accuracy of tonnage requirements, such as worn-out tooling or calibration drift.

Document Adjustments and Results:

Keep a record of any adjustments made based on test bends or previous jobs. This documentation can serve as a valuable reference for future work on similar materials or with similar bend specifications.

Consider Material Springback:

Account for material springback, which is the material’s tendency to return to its original shape after bending. This can affect the final angle and may lead to overcompensation in tonnage if not properly considered.

By following these tips and maintaining an awareness of the risks associated with overestimating tonnage requirements, operators can help ensure that press brake operations are both safe and effective, producing high-quality bends without unnecessary wear on the equipment or the risk of damage to the workpiece.

Similarly, underestimating the tonnage of the bending machine will also have an adverse impact on bending. Everyone should pay attention when calculating the tonnage.

Conclusion

Press Brake Tonnage Charts hold paramount importance for professionals engaged in sheet metal fabrication. These charts provide essential information regarding the force required to bend different materials of varying thicknesses and lengths accurately.

Understanding and effectively utilizing tonnage charts and learn how to calculate tonnage are critical for ensuring the quality and accuracy of the bending process.