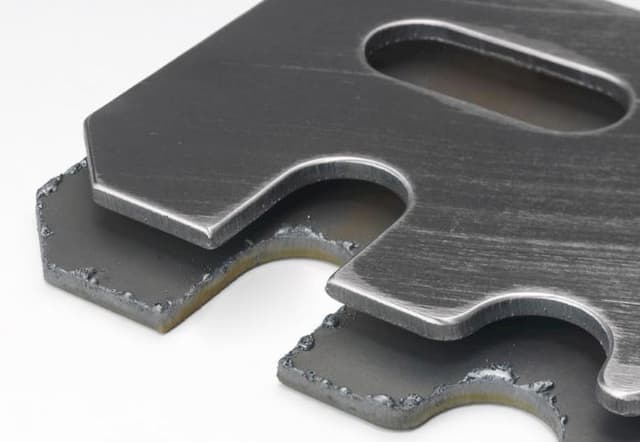

How to prevent burrs in laser cutting? When some customers use cnc fiber laser cutting machines to process sheet metal parts, the cutting effect of the workpiece is very unsatisfactory and there are many burrs. Burrs refer to various irregular metal parts that appear during laser cutting. Burr is one of the common phenomena that occurs in laser cutting machine processing. Burrs directly affect the quality of the workpiece being processed.

Therefore, many users will question the quality of the equipment when using it. But in fact, it's not. In the process of cutting metal sheets, due to improper operation, the materials processed by the laser cutting machine will produce burrs. How to deal with burrs during laser cutting has always troubled everyone.

Burr problem in laser cutting

Burrs refer to various sharp corners, burrs and other irregular metal parts that appear at the transition point of the workpiece surface during laser cutting. Burr is one of the common phenomena produced in laser cutting machine processing. These are also two major problems that have not been solved so far in theoretical research on metal cutting: the generation and control of burrs.

Burrs directly affect the dimensional accuracy, shape accuracy and surface roughness of the workpiece being processed. So how do burrs occur? In fact, burrs are excessive residual particles on the surface of metal materials. If the material has burrs, it can be determined that the material is defective. The more burrs, the lower the quality. What causes burrs when laser cutting machines process metal sheets?

What are the causes of burrs in laser cutting?

Laser cutting uses a focusing mirror to focus the laser beam on the surface of the material to melt, vaporize, and ablate the material. At the same time, compressed gas coaxial with the laser beam is used to blow out the molten material, and the laser beam and the material are opposed along a certain trajectory. Movement to form a cutting seam of a certain shape to complete the cutting of the material. Laser cutting has the advantages of high precision, narrow cutting slit, smooth cutting surface, fast speed, good processing quality, and wide range of processing materials.

At present, laser cutting technology has been widely used in many fields. Complete sets of electrical casings are mostly made of sheet metal parts. Laser cutting has become a common processing method in the sheet metal industry due to its advantages of low processing cost, high efficiency, and wide variety of processing materials. However, the slag and associated burrs attached during the processing are annoying to the on-site managers.

Burrs are easily produced when laser cutting some metal sheets. The occurrence of burrs will affect the accuracy of the processed workpiece and the smoothness of the material surface, and even reduce the quality of the product, causing a lot of inconvenience to subsequent inspection and acceptance work.

So what exactly causes burrs to occur in laser cutting?

By understanding the working principle and daily practice of laser cutting, SC laser cutting machine manufacturer have summarized the causes of burrs, which mainly include the following 7 aspects:

1) Improper material selection. If the selected material is not suitable for laser cutting, it is easy to produce burrs. For example, some materials are easily cut by laser, and burrs will appear.

2) Deviation in the upper and lower position of the laser beam focus causes energy to be unconcentrated. The workpiece is not sufficiently vaporized. The accumulated slag is not easy to fall off and easily produces burrs.

3) The laser power setting is improper. The output power of the light is not enough to effectively evaporate the metal, resulting in a large amount of slag and burrs.

4) The type, purity and blowing pressure of the auxiliary gas of the laser cutting machine do not meet the requirements.

5) The cutting speed is too slow during laser cutting, which will destroy the surface quality of the cutting surface and produce burrs.

6) The working time of the laser cutting machine is too long, causing the equipment to be unstable and causing burrs.

7) There are deficiencies in laser cutting equipment. For example, the sawtooth tray of the laser base has a small serration depth and insufficient taper. Therefore, the contact area with the plate is too large, resulting in obstruction of laser breakdown and gas flow during processing, which can easily cause slag adhesion, slag rebound, and burr formation.

Another aspect is the quality of the equipment itself, as well as parameter setting factors. When customers purchase a laser cutting machine, they must have a professional operator debug the equipment.

The adverse effects of burrs in laser cutting

The presence of burrs in the corners of the workpiece will seriously affect the accuracy of subsequent bending, welding, and assembly, and also pose certain safety risks to operators.

If the workpiece with burrs is applied to the air box of the ring main unit, it will have a great impact on the air tightness; when used in the electrical system, the burrs will fall off, causing a short circuit in the circuit or damaging the magnetic field, affecting the normal operation of the system or causing other hazards.

How to solve burr problems in laser cutting?

During the sheet metal processing process, the parameter settings of the laser cutting machine and the purity of the gas will affect the processing quality. Use appropriate and qualified gas, configure the machine, and adjust the parameters, so that the cut workpiece will not have burrs.

- Adjust equipment parameters: focus position, cutting lead-in position

Some parameter setting factors of the laser cutting machine will also affect the appearance of slag, resulting in burrs on the metal laser cutting machine. Therefore, the cutting parameters must be adjusted to the optimum.

If the focus position is too high, the burrs will increase, and the burrs will be very hard and the sides will not be smooth. It also requires multiple debugging to find the focus position. The lead-in wire should be kept away from the sub-material to prevent local overheating.

After customers purchase a laser cutting machine, it is best to have an experienced operator debug the equipment. According to different processing materials, the power, air pressure, flow rate, focal length, feed speed and other parameters are adjusted repeatedly through practice until they are adjusted to the best state. Save and record the data to facilitate subsequent batch processing. It is impossible to cut exquisite workpieces solely by relying on the parameters provided by the machine.

- Use suitable assist gas

The application of auxiliary gas will also affect the processing quality, so different auxiliary gases should be selected according to different processing materials.

If cutting stainless steel, it is recommended to use nitrogen as auxiliary gas. Nitrogen is usually called an inert gas. During laser processing, nitrogen not only prevents the explosion point phenomenon in laser cutting, but also prevents the heated end surface from instantaneous oxidation. The cut end surface will be smoother and brighter.

The purity of the gas is also critical. Try to choose high-purity gas. The auxiliary gas should be adjusted to a pressure of 12-15 kilograms. The nitrogen at this pressure will not completely prevent combustion, and can also quickly blow away waste and impurities to remove burrs.

sheet and tube fiber laser cutting machine

- Check device accessories

Equipment that has been in disrepair for a long time will also reduce the processing quality and produce burrs due to aging, contamination, and damage of key parts. If the lens is contaminated with oil, has small cracks, or the cutting nozzle is damaged, the transmission of laser power will be affected.

These can be judged by observing whether the light spot formed is round. If the spot is round, it means that the laser energy is distributed evenly in the lateral direction and the cutting quality is high. Cutting quality can also be ensured by regular inspection of key components.

The laser cutting machine is a precision machine, and its operation is also a delicate job. Often a data error will cause its work to run abnormally. Therefore, we must be rigorous and meticulous in our work to reduce and avoid errors. Only by being rigorous and precise in the work, and debugging the equipment, gases, and parameters to the best, can laser cutting be of higher quality.