Índice

O que é raio de curvatura interno

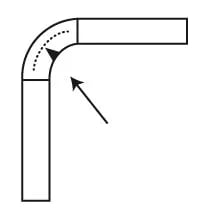

O interior raio de curvatura refere-se à curvatura na superfície interna de uma peça de metal dobrada, normalmente criada durante o processo de dobra em uma prensa dobradeira ou máquina de dobra. Este raio é importante a ser considerado na fabricação de chapas metálicas, pois afeta o formato geral e as dimensões da peça dobrada.

O raio de curvatura interno é determinado por fatores como o ângulo de curvatura, espessura do material, método de curvatura (por exemplo, conformação a ar, curvatura de fundo, cunhagem) e o tipo de matriz usada. É um parâmetro crítico em cálculos de curvatura, pois influencia a tolerância de curvatura, a dedução de curvatura e a precisão geral da peça acabada.

Na formação de ar, o interior raio de curvatura é tipicamente uma porcentagem da abertura da matriz, enquanto na dobra de fundo e cunhagem, é influenciada pelo raio da ponta do punção e pelas características do material. Atingir o raio de dobra interna desejado é essencial para produzir peças que atendam aos requisitos dimensionais e às especificações funcionais.

Como se forma o raio de curvatura

Como exatamente esse raio de curvatura interno é alcançado? Para descobrir isso, precisamos primeiro olhar para os diferentes métodos de curvatura em uma prensa dobradeira: conformação a ar, dobramento inferior e cunhagem.

Cunhagem

Note que há três métodos de dobra, não dois. Dobramento de fundo e cunhagem são frequentemente confundidos com o mesmo processo, mas não são. Ao contrário do fundo, a cunhagem na verdade penetra e afina o material.

A cunhagem é o método mais antigo e, na maior parte, não é mais praticado devido às tonelagens extremas que requer. A cunhagem força o nariz do punção no material, penetrando o eixo neutro (veja a Figura 1). Tecnicamente, qualquer raio pode ser cunhado, mas tradicionalmente a cunhagem tem sido usada para estabelecer uma curva bem acentuada.

Este método não só requer tonelagens excessivas, como também destrói a integridade do material. A cunhagem força todo o perfil da ferramenta a menos que a espessura do material e afina o material no ponto de dobra. Ele requer conjuntos de ferramentas especiais e dedicados para cada dobra e ângulo de dobra. O nariz do punção produz o raio interno, que é usado para estabelecer a dedução da dobra.

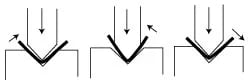

Flexão de fundo

A curvatura inferior força o material ao redor do nariz do punção. Ela usa vários ângulos de punção junto com uma matriz em V (veja a Figura 2). Na cunhagem, toda a face do punção é estampada na peça de trabalho. Na curvatura inferior, apenas o raio do nariz do punção é "estampado" no material.

Na conformação a ar (descrita mais detalhadamente posteriormente), o pistão de punção desce para produzir o ângulo de curvatura necessário mais uma pequena quantidade para compensar o retorno elástico. Então, o punção recua para fora da matriz, e o material retorna ao ângulo desejado. Assim como a conformação a ar, a dobra inferior requer que o pistão desça até um ponto que produz o ângulo de curvatura mais uma pequena quantidade. Mas, diferentemente da conformação a ar, o pistão continua além desse ponto e desce mais para dentro do espaço da matriz, forçando a peça de volta ao ângulo definido da curvatura. (Como uma observação lateral, matrizes especiais como Rolla-Vs e ferramentas de uretano também forçam o raio do nariz do punção no material.)

Em média, a curvatura atinge 90 graus em um ponto no espaço da matriz que é cerca de 20 por cento da espessura do material, conforme medido a partir da parte inferior da matriz em V. Por exemplo, aço laminado a frio de 0,062 pol. de espessura atingirá o fundo quando o nariz do punção estiver de 0,074 a 0,078 pol. da parte inferior da matriz em V.

Assim como na cunhagem, o raio do punch nose estabelece o raio interno do material, que será usado para estabelecer a dedução da curvatura. Mas, diferentemente da cunhagem, o bottoming pode ser usado para produzir raios de curvatura internos de até três vezes ou mais a espessura do material.

Formação de ar

Até aqui, tudo parece bem direto. Com cunhagem e dobramento inferior, o raio do nariz do punção estabelece o valor do raio de dobra interno a ser inserido nas fórmulas para a dedução da dobra. Mas a conformação a ar adiciona alguma complexidade, porque o método de dobra produz um raio de dobra interno na peça de uma forma completamente diferente.

O punção desce (esquerda) até que o material envolva o nariz do punção (centro), após o que o cilindro continua a aplicar pressão para baixo, forçando o material ao ângulo de curvatura desejado (direita).

Na conformação a ar, o raio é produzido como uma porcentagem da abertura da matriz, independentemente do estilo da matriz, seja ela um V, canal ou agudo. A abertura da matriz determina o raio de curvatura interno na peça. Para determinar o raio interno desenvolvido sobre uma determinada abertura da matriz e para vários tipos e espessuras de materiais, os técnicos usaram o que é conhecido como regra dos 20 por cento. Isso afirma que para produzir um raio desejado, ou para encontrar o raio interno resultante, a espessura do material deve ser uma certa porcentagem da largura da abertura da matriz.

Sim, com muitas ligas hoje, incluindo metais novos e reciclados, é impossível determinar um multiplicador percentual padrão com precisão completa. No entanto, a regra lhe dá um bom ponto de partida.

As porcentagens da regra dos 20 por cento são as seguintes:

Aço inoxidável 304: 20-22 por cento da abertura da matriz

Aço laminado a frio AISI 1060, resistência à tração de 60.000 PSI: 15-17 por cento da abertura da matriz

Alumínio macio série H: 13-15 por cento da abertura da matriz

Laminado a quente, decapado e oleado (HRPO): 14-16 por cento da abertura da matriz

Ao trabalhar com essas porcentagens, comece com a mediana até encontrar o valor que melhor corresponde às características do material que você recebe do seu fornecedor de metal. Multiplique a abertura pela porcentagem para obter o raio interno desenvolvido da peça. O resultado final será o valor do raio interno que você precisa usar ao calcular a dedução da dobra.

Se você tem uma abertura de matriz de 0,472 pol. e está dobrando aço laminado a frio de 60.000 PSI, comece com a porcentagem mediana, 16 por cento da abertura da matriz: 0,472 × 0,16 = 0,0755. Então, neste caso, uma abertura de matriz de 0,472 pol. lhe dará um raio de curvatura interno flutuado de 0,0755 pol. na peça.

Quando a abertura da matriz muda, o raio interno também muda. Se a abertura da matriz for 0,551 pol. (0,551 × 0,16), o raio de curvatura interno muda para 0,088; se a abertura da matriz for 0,972 pol. (0,972 × 0,16), o raio de curvatura interno muda para 0,155.

Se você estiver trabalhando com aço inoxidável 304, multiplique seu valor percentual mediano — 21 por cento — pela abertura da matriz. Então, essa mesma abertura de 0,472 pol. da matriz agora fornece um raio interno muito diferente: 0,472 × 0,21 = 0,099 pol. Como antes, quando você altera a abertura da matriz, você altera o raio de curvatura interno. Uma abertura de matriz de 0,551 pol. (0,551 × 0,21) calcula um raio interno de 0,115 pol.; uma abertura de matriz de 0,972 pol. (0,972 × 0,21) fornece um raio de curvatura interno de 0,204 pol.

Se você mudar o material, você muda a porcentagem. Se você trabalha com material não listado aqui, você pode procurar o material na Internet e comparar as resistências à tração com o valor de base de 60.000 PSI para aço laminado a frio AISI 1060. Se o valor de tração for 120.000 PSI, então seu valor percentual estimado será duas vezes maior que o do aço laminado a frio, ou 30 a 32 por cento.

Curvas acentuadas na formação de ar

Ao contrário do bottoming ou do cunhamento, há um raio mínimo que pode ser produzido com a conformação a ar. Esse valor é melhor definido em 63 por cento da espessura do material. Esse valor sobe ou desce com base na resistência à tração do material, mas 63 por cento é um valor prático de trabalho.

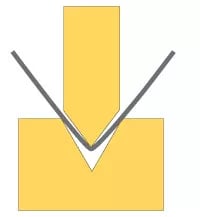

Este ponto de raio mínimo é o que é conhecido como uma curva acentuada (veja a Figura 4). Entender os efeitos de curvas acentuadas é, sem dúvida, uma das coisas mais importantes que um engenheiro e operador de prensa dobradeira precisam saber. Você não só precisa entender o que está acontecendo fisicamente quando a curva é acentuada, mas também precisa saber como incorporar essas informações em seus cálculos.

O raio é produzido como uma porcentagem da abertura da matriz, independentemente do estilo da matriz.

Se você estiver trabalhando com uma espessura de material de 0,100 pol., multiplique isso por 0,63 para obter um raio de curvatura interno mínimo de 0,063 pol. Para esse material, esse é o raio interno mínimo produzível com conformação a ar. Isso significa que, mesmo se você estivesse conformando a ar com um raio de ponta de punção menor que 63 por cento da espessura do material, o raio interno da peça ainda seria 63 por cento da espessura do material, ou 0,063 pol. Portanto, não use nenhum raio interno menor que esse valor de 63 por cento em seus cálculos.

Digamos que você esteja formando ar com material de 0,250 pol. de espessura e usando um punção com um raio de ponta de 0,063 pol. — um valor muito menor que 63 por cento da espessura do material de 0,250 pol. Independentemente do que é chamado na impressão, essa configuração produzirá um raio de curvatura interno na peça muito maior do que o da ponta do punção. Nesse caso, o raio de curvatura interno mínimo produzível é 63 por cento dessa espessura de material de 0,250 pol., ou 0,1575 pol.

Como outro exemplo, digamos que você esteja trabalhando com material de 0,125 pol. de espessura. Para isso, uma dobra "fica acentuada" em um raio de 0,078 pol. Por quê? Porque 0,125 multiplicado por 63 por cento dá 0,078. Isso significa que qualquer raio de ponta de punção menor que 0,078 pol. — seja 0,062, 0,032 ou 0,015 pol. — produzirá um raio de dobra interno de 0,078 pol.

Curvas acentuadas são uma função da espessura do material, não do raio do punção. Um punção de raio de 0,125 pol. não é afiado ao toque, mas para material de 0,250 pol. de espessura, é. E essa questão precisa ser abordada em seus cálculos se você espera que a dedução da curvatura e, portanto, sua primeira peça, esteja correta.

Um plano de ação

Na formação de fundo ou cunhagem, use o raio do nariz do punção como o raio de curvatura interno em seus cálculos de dedução de curvatura. Mas se você estiver formando a ar, o raio de curvatura interno é produzido como uma porcentagem da abertura da matriz. E se você estiver projetando para uma formação a ar e a impressão exigir uma curvatura acentuada, isso também precisará ser alterado para um valor de raio de curvatura interno que seja 63 por cento da espessura do material.

Se você trabalha com engenharia, tente obter uma lista de todas as ferramentas disponíveis em sua oficina. Converse com os operadores e descubra quais métodos eles estão usando com quais tipos de materiais, e projete suas futuras peças em torno desses parâmetros.

Depois que as deduções de dobra forem calculadas e as peças planas forem produzidas, anote essas informações no job jacket ou na pasta de trabalho. Certifique-se de incluir o tipo e o tamanho da ferramenta e o raio que você deseja que o operador alcance com base no método de conformação.

Fazer tudo isso funcionar requer a adesão dos trabalhadores do chão de fábrica. Incluí-los no processo e pedir a opinião deles os deixará muito mais dispostos a aceitar que a engenharia está dizendo a eles quais ferramentas usar. Por quê? Porque eles disseram a você o que fazem e sabem que você está projetando peças com base nisso. Idealmente, tudo isso corresponderá aos valores calculados no controlador de freio de prensa e pelo seu sistema CAD.

Se o raio for atingível, se a peça for calculada para esse raio e se os operadores usarem as ferramentas para as quais o trabalho foi projetado, eles produzirão uma peça perfeita na primeira tentativa. Confie em mim. Funciona.

Fórmulas de Dobra

Tolerância de curvatura (BA) = [(0,017453 × Raio interno) + (0,0078 × Espessura do material)] × Ângulo de curvatura complementar

Figura 4: Ao formar o ar, você não pode formar um raio de curvatura interno menor que 63 por cento da espessura do material,

em que ponto a forma é chamada de curva acentuada. Se você usar um raio de punção mais acentuado, você forçará apenas uma vala

no centro da curvatura. O raio de curvatura interno resultante na peça permanecerá em 63 por cento da espessura do material.

Recuo externo (OSSB) = [Tangente (grau de ângulo de curvatura / 2)] × (raio de curvatura interno + espessura do material)

Dedução de Curvatura (BD) = (Recuo externo × 2) – Tolerância de curvatura Existem duas maneiras de calcular o blank plano. O cálculo a ser usado depende da aplicação e das informações disponíveis:

Cálculo de plano-branco = Dimensão até o ápice + Dimensão até o ápice – Dedução de dobra

Cálculo de chapa plana = dimensão da primeira perna + dimensão da segunda perna + margem de curvatura