Máquina de corte a laser de fibra

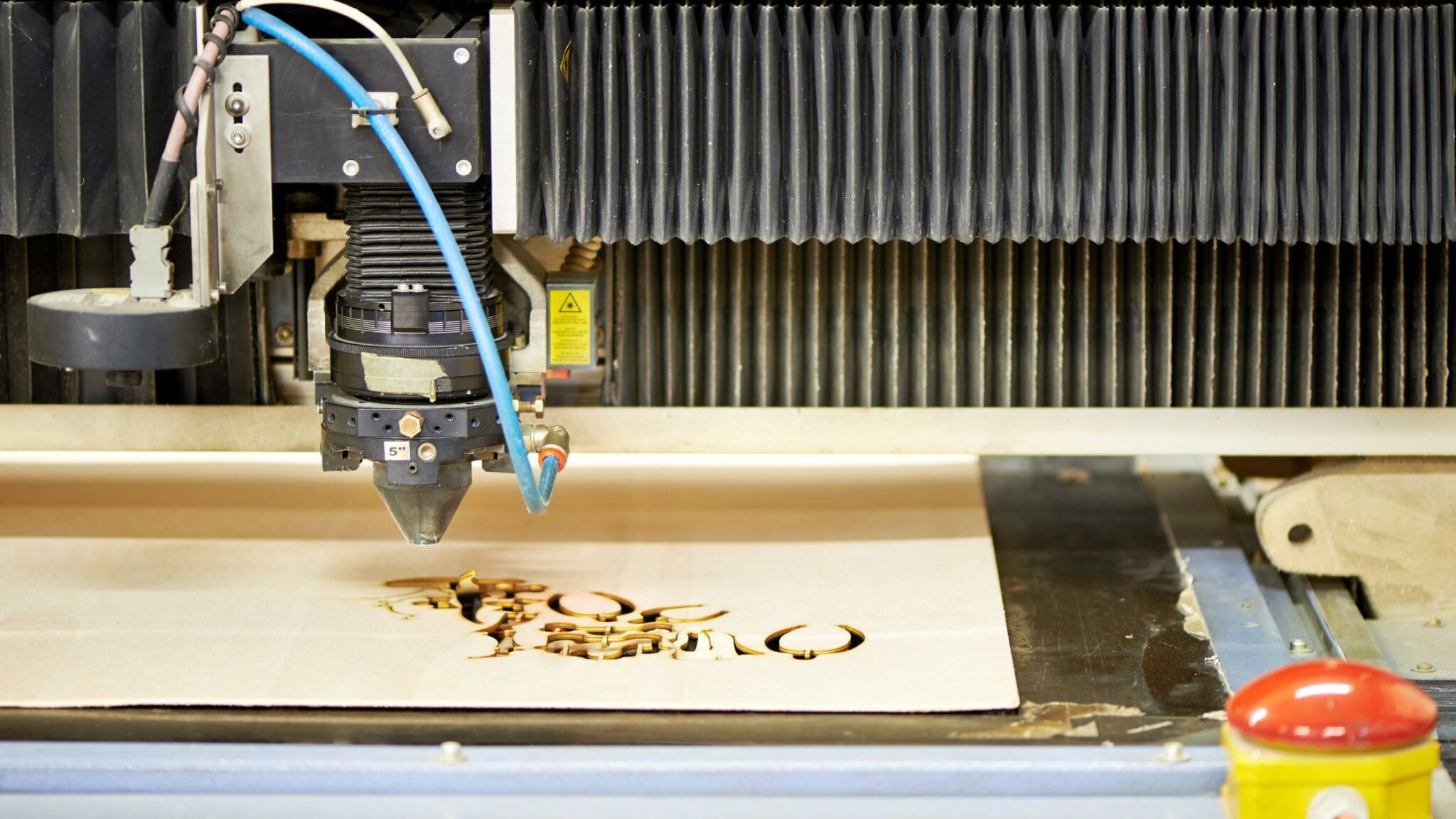

Máquinas de corte a laser de fibra são dispositivos avançados controlados por computador que utilizam um feixe de laser para cortar e gravar com precisão vários materiais, incluindo metal, plástico, madeira e papel. O feixe de laser é habilmente direcionado para a superfície do material, induzindo processos como derretimento, queima ou vaporização para criar padrões ou designs intrincados. Essas máquinas de ponta encontram aplicações generalizadas em diversas indústrias, incluindo manufatura, engenharia e design gráfico, graças à sua precisão, velocidade e versatilidade excepcionais em comparação aos métodos de corte tradicionais.

Notavelmente, as máquinas de corte a laser se destacam no manuseio de designs complexos e intrincados que podem ser desafiadores ou impossíveis com técnicas alternativas. Sua principal vantagem está na precisão e exatidão alcançadas por meio do controle preciso do feixe de laser, permitindo cortes limpos com desvio mínimo. Além da precisão, essas máquinas ostentam capacidades de alta velocidade, facilitando a produção eficiente de alto volume. Além disso, suas operações geram desperdício mínimo devido à natureza limpa e precisa dos cortes, reduzindo assim a necessidade de processos adicionais como retificação ou lixamento.

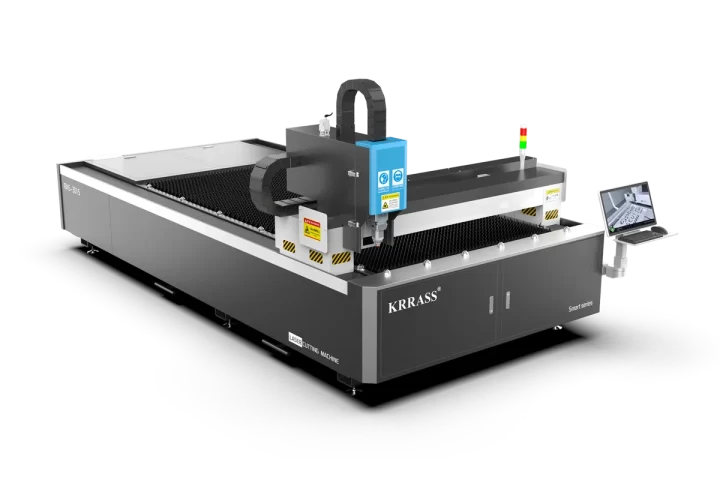

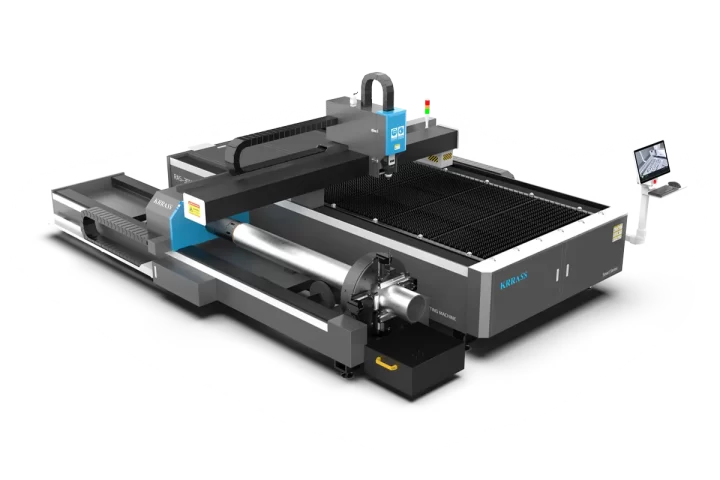

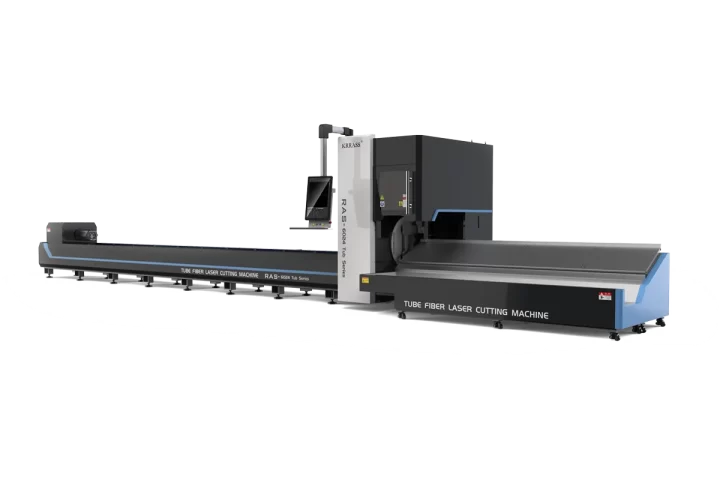

No reino das soluções de controle de corte a laser, a KRRASS se destaca como uma fornecedora confiável, fornecendo soluções de hardware e software de classe mundial. Nossa abordagem turnkey introduz automação robusta para dar suporte a máquinas de alto desempenho. Recursos como acompanhamento de altura maximizam o tempo de trabalho da máquina, enquanto mecanismos inteligentes navegam ativamente sobre as peças cortadas, evitando colisões e erros no planejamento do caminho. Eleve suas capacidades de produção com a KRRASS - líder no fornecimento de soluções poderosas para o mercado de controle de corte a laser.

Lista de máquinas de corte a laser de fibra

Entre em contato

Caso tenha alguma dúvida, entre em contato conosco. Entraremos em contato o mais breve possível.

Telefone

+86 189 5208 7956

Localização

Nanquim, Jiangsu, China

Social

Características estruturais

Controlador de corte a laser

No reino da fabricação de precisão, o sistema de controle CNC de barramento dedicado para corte a laser surge como um ápice da inovação tecnológica. Adaptado especificamente para as complexidades únicas dos processos de corte a laser, este sistema avançado fornece uma solução perfeita e eficiente. Empresas que buscam precisão e controle inigualáveis em seus fluxos de trabalho de fabricação encontram neste sistema de controle CNC de barramento dedicado um aliado confiável, garantindo desempenho ideal e capacidades aprimoradas no reino do corte a laser.

| Modelo | Poder | Aplicativo | Perfuração | Características | Bancada de troca |

|---|---|---|---|---|---|

| FSCUT1000S | 1000~1500W | Sistema de placa de baixa potência | 2 estágios | Layout simples; Corte de mosca | X |

| FSCUT2000C | 1000~4000W | Sistema de placa de baixa e média potência | Layout simples; Um clique para cortar; Localização automática de bordas; Corte de mosca | ||

| FSCUT3000S | 1000~4000W | Sistema de controle de corte de tubos | Corte de aço em canal; Corte os custos individualmente; Carregamento e descarregamento automático; Todas as funções do FSCUT2000 | ||

| FSCUT2000E | 1000~6000W | Sistema de controle de corte a laser de baixa e média potência | Um clique para cortar; Borda do envelope; Um golpe de corte voador; Centralização de disco | √ | |

| FSCUT3000DE | 1000~6000W | Controlador EtherCAT para corte a laser de tubo de 1 mandril | Classificar por rosto; Mecanismo de centralização; Prevenção de cortes perdidos; Corte de mosca | ||

| FSCUT4000E | 1,5 kW-8 kW | Sistema de controle de corte a laser de circuito fechado | Perfuração insensível; Microconexão sem rastros; Centralização de disco; Um golpe de corte voador; Escaneie o código para ler as imagens; Borda do envelope | ||

| FSCUT5000 | 1000~6000W | Sistema de controle de corte de tubos | Corte sem cauda; Puxada de 7 eixos; Corte chanfrado; Corte com 3 mandris; Corte de 4 mandris | ||

| FSCUT6000 | 6-15 kW | Sistema de barramento EtherCAT de alta potência | Perfuração insensível; Microconexão sem rastros; Centralização de disco; Relâmpago perfurante; Perfuração e remoção de escória; Supressão de vibração inteligente | ||

| FSCUT7000 | 1000~4000W | Sistema de controle de corte a laser de precisão | Técnica de linha de transição; Linha de chumbo; Corte à mosca; Ponto de viragem de velocidade; Ajuste de velocidade na posição de curva | ||

| FSCUT8000 | ≥8 kW | Sistema de barramento EtherCAT de ultra alta potência | 9 estágios | Fechamento inteligente de faca; Microconexão sem rastros; Comutação automática; Inspeção de poça de fusão; Perfuração inteligente |

Saiba mais >>

Cabeça de corte inteligente

Revolucionando o corte a laser, o Smart Cutting Head integra recursos inteligentes para precisão aprimorada. Com sensores avançados e monitoramento em tempo real, ele se adapta dinamicamente aos materiais, otimizando os parâmetros de corte. Esta solução compacta automatiza perfeitamente os processos, inaugurando uma nova era de precisão em aplicações de corte a laser.

| Modelo | Poder | Aplicativo | Interface de fibra | Características |

|---|---|---|---|---|

| BLT3 | ≤4 kW | Cabeçote de corte inteligente de baixo custo e potência média | QBH / EOC | Design estilo gaveta para conjunto de espelhos; Proteção contra colisões; Monitoramento de contaminação do espelho protetor; Monitoramento da pressão do ar; Nível de proteção IP64 |

| BLT4 | ≤30 kW | Cortador inteligente de baixo custo com foco em máquinas de corte 2D, 3D e chanfrado | QBH / EOC / Q+ / QD / ADD | Corte estável e eficiente; Fácil de manter; Baixo custo de reparo; Processamento inteligente e seguro |

| BLT5 | ≤15 kW | Cortadores inteligentes para corte de tubos de alta potência | QBH / EOC / Q+ / QD / ADD | Corte chanfrado; Cortador de ângulo reto; Parafusos de proteção; Monitor de pressão de gás; Amplificador Interno |

| BLT6 | ≤40 kW | Para equipamentos de laser de ultra-alta potência | QBH / Q+ / QD / ADICIONAR | Corte estável e eficiente; Piercing Inteligente; Corte sem escória; Fácil de manter; Baixo custo de reparo; Processamento inteligente e seguro; Monitor de Lente Protetora |

Saiba mais >>

Vídeo da máquina de corte a laser

Transforme seus procedimentos de corte com a tecnologia de corte a laser de fibra de última geração

Máquina de corte a laser Blogue

Descubra as capacidades da sua máquina de corte a laser: Um guia detalhado sobre a tecnologia de corte a laser

Corte a Laser Kerf: Um Guia Completo

krrass

Na fabricação de precisão, o corte a laser representa o epítome da precisão e eficiência. Este guia aprofunda ...

Ler mais

Corte a jato de água vs corte a laser de fibra: qual é a diferença

krrass

No cenário contemporâneo de fabricação e manufatura, atingir precisão e eficiência não é negociável. Selecionando o...

Ler maisMáquina de corte a laser Perguntas frequentes

Como resolver as dificuldades da máquina de corte a laser de fibra?

Velocidade de corte

A velocidade de corte rápida é uma das vantagens do corte a laser, mas a velocidade de corte não é tão rápida quanto possível.

Assista The Cutting Sparks

Quando a velocidade de corte é adequada, as faíscas de corte são distribuídas de forma mais uniforme de cima para baixo;

Observe a folha de corte

Quando a velocidade de corte é adequada, a superfície de corte apresenta uma linha relativamente suave e nenhuma escória é produzida na metade inferior.

Bico e altura do bico

O bico atua como um feixe e canal de gás auxiliar. O formato, a abertura e a altura do bico afetarão o efeito de corte.

Pressão de gás de proteção

O tamanho da pressão do gás auxiliar também afeta o efeito de corte da máquina de corte a laser de fibra. Ajustar a pressão do ar também pode melhorar o efeito de corte:

Precauções para desligar a máquina de corte a laser de fibra

Primeiro, mova a cabeça de corte para o ponto mais alto e pare os eixos X e Y na posição segura. Troque a bancada ou pare a bancada em um local seguro.

Como escolher a máquina de solda híbrida a laser e arco?

Histórico técnico

A soldagem de chapas de aço de média e grande espessura é usada principalmente em transporte ferroviário, construção naval, equipamentos de energia nuclear e outras indústrias.

Características técnicas

Existem muitas formas de soldagem híbrida a laser e arco, incluindo soldagem híbrida a laser-MAG/MIG, soldagem híbrida a laser-TIG, soldagem híbrida a laser e arco de plasma, etc.

Aplicações

Soldagem de liga de alumínio

Requisitos: a soldagem sob medida de ligas de alumínio de 5 mm e 6 mm requer boa formação de solda e nenhum defeito de rebaixo.

Soldagem de chapas médias e grossas de navios

Requisitos: A soldagem personalizada de chapas de aço marítimo AH36 com espessuras de 6 mm e 12 mm exige que a formação e a qualidade da solda atendam aos requisitos do Padrão de Qualidade de Construção Naval Chinês (GB/T 34000-2016).

Soldagem multi-passe de chapas de navio de grande espessura

Requisitos: chapas de aço marítimo de ultra-alta resistência de 20 mm e 25 mm de espessura são soldadas sob medida, e a formação e a qualidade da solda devem atender aos requisitos do padrão de qualidade de construção naval chinês (GB/T 34000-2016).

Sugestão de parâmetros de equipamento e processo

Atualmente, há muito poucas aplicações práticas para a tecnologia de soldagem híbrida a laser e arco na China, e não há nenhuma conquista sistemática até o momento.