A importância de pequenas prensas dobradeiras CNC estende-se além de suas capacidades técnicas. Elas representam um avanço crítico na metalurgia, oferecendo precisão e repetibilidade inigualáveis, que são cruciais para manter os padrões de qualidade em produtos acabados. Ao automatizar o processo de dobra e reduzir o erro humano, essas máquinas aumentam a eficiência da produção e minimizam o desperdício de material. Além disso, seu design compacto as torna ideais para oficinas de pequeno e médio porte, onde maximizar cada metro quadrado é vital.

Este guia tem como objetivo fornecer uma compreensão aprofundada de pequenas prensas dobradeiras CNC, explorando suas principais características, principais marcas e fatores a serem considerados ao fazer uma compra. Quer você esteja procurando atualizar as capacidades da sua oficina ou investir na sua primeira prensa dobradeira CNC, este guia abrangente ajudará você a tomar uma decisão informada.

O que é prensa dobradeira CNC

Uma Prensa Dobradora CNC (Controle Numérico Computadorizado) é uma máquina sofisticada e automatizada projetada para dobrar chapas de metal. Usando programação de computador, ela controla precisamente vários aspectos do processo de dobra, incluindo o ângulo, a profundidade e o comprimento da dobra. O sistema CNC interpreta essas instruções para posicionar com precisão as ferramentas de dobra. Esse alto nível de automação resulta em dobra rápida e precisa, minimizando o erro humano e aumentando a produtividade. As Prensas Dobradoras CNC são versáteis e flexíveis, capazes de executar tarefas complexas de dobra e integrar-se perfeitamente a outros processos de fabricação.

Que toneladas tem essa prensa dobradeira CNC

As prensas dobradeiras CNC vêm em uma ampla gama de capacidades de tonelagem, dependendo do fabricante e do modelo específico. A tonelagem de uma prensa dobradeira CNC se refere à quantidade máxima de força que a máquina pode aplicar à chapa de metal que está sendo dobrada. Tonelagens comuns para prensas dobradeiras CNC variam de:

- 30 a 100 toneladas: Adequado para tarefas de dobra leves a moderadas e tamanhos de folhas menores.

- 100 a 300 toneladas: Ideal para aplicações de médio a pesado porte, lidando com chapas maiores e dobras mais complexas.

- 300 a 500 toneladas: Utilizado para operações de dobra pesadas, capaz de lidar com chapas muito grandes e requisitos de dobra significativos.

- 500 toneladas e acima: Projetado para tarefas extremamente pesadas, acomodando folhas grandes e materiais muito grossos.

Ao selecionar uma prensa dobradeira CNC, é importante escolher uma com tonelagem suficiente para atender às suas necessidades específicas de dobra, considerando fatores como tamanho da folha, espessura do material e complexidade das dobras.

Como definir "Prensa Dobradora CNC Pequena"

Um "pequena prensa dobradeira CNC" é normalmente definido por seu tamanho compacto e menor capacidade de tonelagem em comparação aos modelos maiores.

Uma pequena prensa dobradeira CNC é caracterizada por seu tamanho compacto e menor capacidade de tonelagem, geralmente variando de 30 a 100 toneladas. Isso a torna bem adequada para tarefas de dobra mais leves e de menor escala. O comprimento de trabalho de uma pequena prensa dobradeira CNC é geralmente entre 1 a 3 metros (aproximadamente 3 a 10 pés), permitindo que ela manipule tamanhos menores de folhas de forma eficiente. Sua pegada compacta a torna ideal para oficinas com espaço limitado.

Projetadas para lidar com materiais mais finos e folhas menores, as pequenas prensas dobradeiras CNC são frequentemente usadas para prototipagem, produção de pequenos lotes e em ambientes onde o espaço é escasso. Além disso, elas são mais acessíveis do que modelos maiores, tornando-as uma opção econômica para lojas menores ou empresas com restrições orçamentárias.

Características da pequena prensa dobradeira CNC

As prensas dobradeiras pequenas são projetadas para serem fáceis de usar e eficientes, permitindo configuração e conclusão rápidas de tarefas de dobra. Elas geralmente ocupam menos espaço, o que as torna mais fáceis de encaixar em espaços de trabalho menores. Apesar do tamanho compacto, as prensas dobradeiras pequenas ainda oferecem capacidades de dobra excepcionais e são capazes de atingir resultados precisos e consistentes.

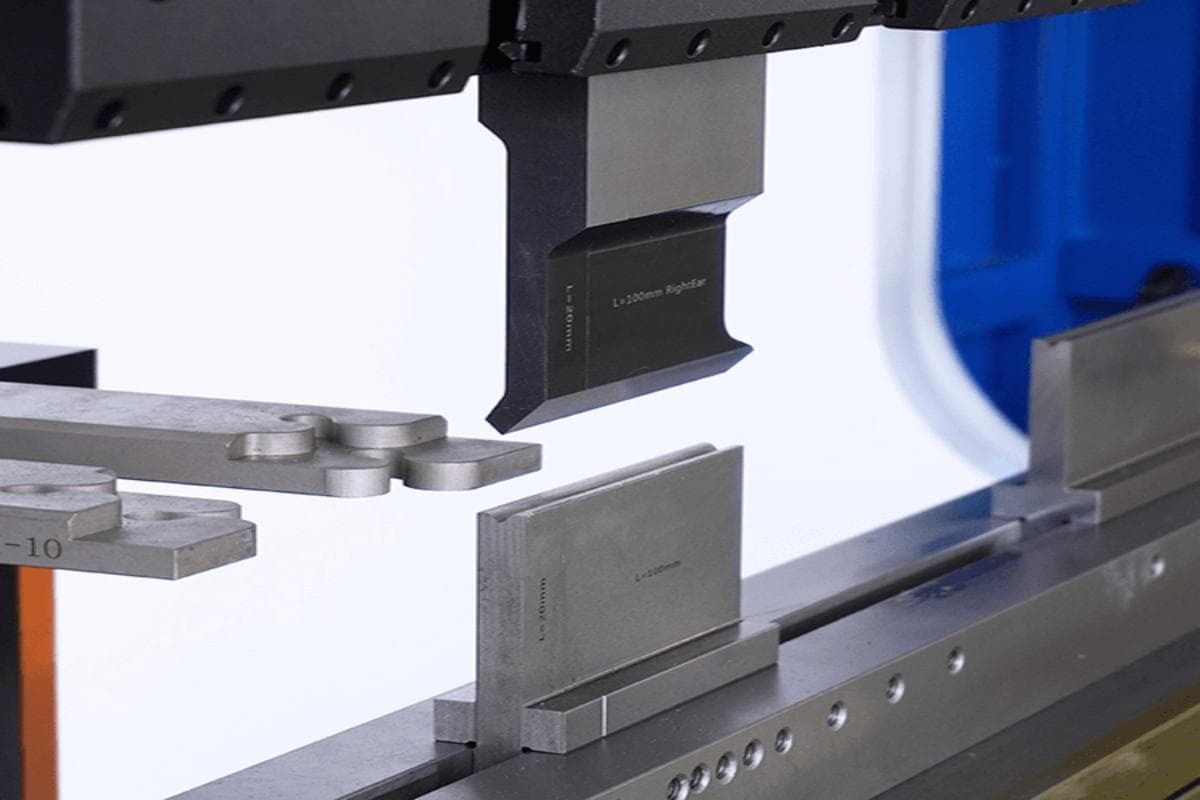

Essas máquinas são equipadas com vários recursos que melhoram sua funcionalidade e facilidade de uso. Elas geralmente vêm com batentes ajustáveis, permitindo o posicionamento preciso da chapa metálica. Algumas prensas dobradeiras pequenas também têm displays digitais e controles programáveis, permitindo que os operadores insiram ângulos de dobra e dimensões específicos para maior precisão. Além disso, muitas prensas dobradeiras pequenas são equipadas com recursos de segurança, como botões de parada de emergência e proteções, garantindo o bem-estar dos operadores.

No geral, as pequenas prensas dobradeiras são uma ferramenta essencial para profissionais na indústria de fabricação de metal. Elas oferecem precisão, eficiência e recursos fáceis de usar, tornando-as uma escolha popular para tarefas de dobra em oficinas menores. Com seu tamanho compacto e capacidades versáteis, as pequenas prensas dobradeiras contribuem para maximizar a produtividade e fornecer resultados consistentes no processo de dobra de metal.

Benefícios de usar uma pequena prensa dobradeira CNC

Eficiência de espaço:

O design compacto de pequenas prensas dobradeiras CNC permite que elas se encaixem em espaços apertados de oficina, tornando-as ideais para ambientes com área de piso limitada. Esse uso eficiente do espaço ajuda a maximizar a produtividade e permite posicionamento versátil perto de outras máquinas ou em estações de trabalho dedicadas, facilitando um fluxo de trabalho simplificado. Seu tamanho menor garante que o valioso espaço da oficina seja utilizado de forma eficaz, aumentando a eficiência operacional geral.

Custo-benefício:

As pequenas prensas dobradeiras CNC são geralmente mais acessíveis do que os modelos maiores, apresentando uma opção atraente para startups ou pequenas empresas com orçamentos limitados. O menor investimento inicial é complementado por custos operacionais reduzidos, incluindo menor consumo de energia e necessidades de manutenção. Essa combinação de acessibilidade e eficiência de custo torna essas máquinas uma escolha prática para aqueles que buscam otimizar seus recursos financeiros e ainda obter capacidades de dobra de alto desempenho.

Precisão e automação:

As pequenas prensas dobradeiras CNC alavancam a tecnologia CNC avançada para fornecer alta precisão e automação no processo de dobra. Isso garante que as dobras sejam executadas com precisão exata, incluindo controle preciso sobre ângulo, profundidade e comprimento. Ao reduzir o erro humano e garantir resultados consistentes, essas máquinas melhoram a qualidade e a confiabilidade do produto, tornando-as indispensáveis para aplicações onde a precisão é primordial.

Versatilidade:

Apesar do seu tamanho menor, as pequenas prensas dobradeiras CNC oferecem uma versatilidade impressionante, acomodando uma ampla gama de tarefas, desde prototipagem até produção em pequenos lotes. Elas são capazes de lidar com vários materiais e espessuras, proporcionando flexibilidade na fabricação. Essa adaptabilidade as torna adequadas para diversas aplicações e permite que as empresas lidem com operações de dobra de rotina e especializadas com facilidade.

Configuração e retorno rápidos:

As pequenas prensas dobradeiras CNC são projetadas para configuração rápida e ajustes rápidos, o que facilita tempos de resposta rápidos entre os trabalhos. Essa eficiência é particularmente benéfica para lidar com pequenas tiragens de produção ou pedidos personalizados, permitindo que as empresas cumpram prazos apertados e melhorem a produtividade geral. A capacidade de se adaptar rapidamente a diferentes tarefas e configurações oferece suporte a um processo de fabricação mais ágil e responsivo.

Custos operacionais mais baixos:

O menor consumo de energia e o desgaste reduzido associados a pequenas prensas dobradeiras CNC contribuem para seus menores custos operacionais. Isso inclui economia em contas de energia e manutenção menos frequente, que juntas ajudam a minimizar despesas de longo prazo. Essas economias de custo aumentam a proposta de valor geral da máquina, tornando-a uma opção economicamente viável para empresas conscientes de custos.

Flexibilidade na Produção:

As pequenas prensas dobradeiras CNC oferecem flexibilidade significativa para lidar com trabalhos personalizados e necessidades de produção variadas. Sua capacidade de se adaptar a diferentes tarefas de dobra e materiais as torna um recurso valioso em ambientes de fabricação dinâmicos. Essa adaptabilidade oferece suporte a uma variedade de aplicações, de tarefas especializadas a projetos personalizados, garantindo que as empresas possam atender com eficiência a diversos requisitos de produção.

Onde uma pequena prensa dobradeira CNC se encaixa

Uma pequena prensa dobradeira CNC é particularmente adequada para vários ambientes devido ao seu tamanho compacto e capacidades versáteis. Em pequenas oficinas, sua pegada limitada é ideal para maximizar o espaço, ao mesmo tempo em que fornece dobra de alto desempenho. Isso a torna uma excelente escolha para ambientes com área de piso restrita. Da mesma forma, em instalações de prototipagem, a precisão da máquina e a capacidade de lidar com tarefas de dobra personalizadas dão suporte a ajustes rápidos e produção rápida, o que é crucial para processos de design iterativos e criação de protótipos.

Para produção em pequenos lotes, uma pequena prensa dobradeira CNC oferece soluções econômicas ao lidar com pequenas tiragens de produção com alta precisão, tornando-a mais econômica do que máquinas maiores. Instituições educacionais se beneficiam de seu design compacto e capacidades práticas, permitindo que os alunos ganhem experiência com tecnologia CNC em espaços limitados. Oficinas de fabricação personalizadas e oficinas de manutenção e reparo também encontram valor em sua versatilidade, pois podem acomodar vários materiais e tarefas, de projetos personalizados a pequenos reparos.

Startups e pequenas empresas apreciam sua acessibilidade e menores custos operacionais, fornecendo um ponto de entrada acessível para dobra CNC. Finalmente, para fabricação interna, oferece produção sob demanda e maior controle sobre o processo de fabricação, permitindo que as empresas se adaptem rapidamente às necessidades de produção.

TOP 5 Fabricantes de Pequenas Prensas Dobradeiras

1. AMADA

Marca: Japão, fundada em 1946

A fabricante de prensas dobradeiras AMADA é uma grande empresa internacional em máquinas de processamento de chapas metálicas. Eles fornecem máquinas para chapas metálicas, prensas dobradeiras Amada, máquinas de corte, retificadoras, prensas de estampagem e máquinas de soldagem de precisão.

A Amada é uma empresa japonesa fundada em 1946 com uma longa história. Os produtos da Amada têm uma estrutura mecânica abrangente e razoável, fornecendo aos usuários a melhor garantia de qualidade.

2. Trumpf

Marca: Alemã, Fundada em 1923

Alemanha Trumpf é uma empresa inovadora de alta tecnologia, dividida em três partes: Máquinas-ferramentas (prensa dobradeira Trumpf, tesoura), tecnologia laser e eletrônica. É um dos melhores fabricantes de máquinas de fabricação de chapas metálicas, lasers industriais e produtos eletrônicos de aplicação industrial do mundo.

A TRUMPF está orientando a tendência de desenvolvimento tecnológico com inovação contínua, estabelecendo novos padrões técnicos e está comprometida em desenvolver e atualizar mais produtos para a maioria dos usuários.

3. Precisão

Marca: Canadá, fundada em 1973

A Accupress é uma fabricante profissional de máquinas-ferramentas CNC, fundada no Canadá em 1973. Ela fabrica principalmente prensas dobradeiras Accupress, máquinas de corte, ferramentas e outros produtos periféricos.

A Accupress é especializada em prensas dobradeiras tandem de grande tonelagem e automação de robôs. A Accupress é conhecida por sua alta qualidade de fabricação e tecnologia avançada.

4. Bystronic

Marca: Itália, fundada em 1964

A Bystronic é uma fornecedora mundialmente famosa de soluções de processamento de chapas metálicas, fundada na Suíça em 1964.

A empresa se concentra na automação de todo o fluxo de materiais e dados da cadeia de processos de corte e dobra.

A Bystronic fornece principalmente máquinas de corte a laser, prensas dobradeiras, sistemas de automação e softwares relacionados.

5. Durma

Marca: Turquia, fundada em 1956

A Durmazlar Machinery foi fundada por Ali Durmaz em 1956. O fabricante de prensas dobradeiras Durma é uma base de processamento de chapas metálicas de renome mundial.

Os produtos da Durma incluem prensas dobradeiras CNC Durma, prensas de torre, puncionadeiras, lasers de fibra totalmente de estado sólido, tesouras, máquinas de corte de ferro, rolos de chapa, rolos angulares e serras.

Fatores a considerar ao escolher uma pequena prensa dobradeira

Quando se trata de selecionar uma pequena prensa dobradeira para suas necessidades de dobra de metal, há alguns fatores-chave a serem considerados. Ao considerar cuidadosamente esses fatores, você pode garantir que escolheu a máquina certa para sua oficina. Aqui estão alguns pontos importantes a serem lembrados:

- Tamanho e capacidade: A primeira coisa que você precisa determinar é o tamanho e a capacidade da prensa dobradeira que melhor atenderá às suas necessidades. Considere o comprimento e a espessura máximos dos materiais com os quais você trabalhará e escolha uma máquina que possa lidar com eles de forma eficiente. É importante encontrar um equilíbrio entre o tamanho da máquina e o tamanho dos materiais com os quais você normalmente trabalha.

- Recursos e controles: Preste atenção aos recursos e controles oferecidos pela pequena prensa dobradeira. Procure por batentes ajustáveis, controles programáveis e outros recursos que irão melhorar sua precisão e exatidão em tarefas de dobra. Esses recursos podem melhorar muito sua eficiência e produtividade no processo de fabricação de metal.

- Facilidade de uso: Uma pequena prensa dobradeira deve ser fácil de usar, mesmo para aqueles com experiência limitada. Procure uma máquina que ofereça controles intuitivos e instruções claras. Uma prensa dobradeira amigável ao usuário economizará seu tempo e frustração a longo prazo.

- Durabilidade e confiabilidade: Você quer uma pequena prensa dobradeira que seja feita para durar. Procure uma máquina feita de materiais de alta qualidade que possam suportar as demandas do uso diário. Além disso, considere a reputação e o histórico do fabricante para garantir que você esteja investindo em um produto confiável.

- Preço e valor: Por fim, considere o preço e o valor da pequena prensa dobradeira. Embora você queira ficar dentro do seu orçamento, é importante lembrar que a qualidade e o desempenho não devem ser comprometidos. Procure uma máquina que ofereça um bom equilíbrio entre preço e valor, e considere os benefícios de longo prazo que ela trará para sua oficina.

Prensa CNC maior vs. prensa dobradeira pequena, como escolher

Cada loja é única, e entender suas necessidades específicas é essencial para selecionar o equipamento certo. Uma pequena prensa dobradeira CNC pode ser uma excelente escolha se suas operações envolverem tarefas como:

- Dobrando peças pequenas ou complexas: Ideal para manusear peças intrincadas ou menores que exigem dobras precisas. Essa versatilidade também se estende para acomodar algumas peças maiores quando necessário.

- Reduzindo desperdícios e eliminando rejeições: Ao garantir uma dobra precisa, uma pequena prensa dobradeira CNC minimiza o desperdício de material e reduz a probabilidade de rejeições, melhorando a eficiência geral e a relação custo-benefício.

- Produzindo uma variedade de materiais e peças: Capaz de trabalhar com uma ampla variedade de materiais e produzir peças diversas, uma pequena prensa dobradeira CNC com um único conjunto de punções e matrizes pode agilizar suas operações e reduzir a necessidade de múltiplas ferramentas.

- Economizando em custos de matriz de dobra: Com a capacidade de executar diversas tarefas de dobra usando menos matrizes, você pode reduzir os custos associados à compra e manutenção de ferramentas de dobra, tornando-as uma escolha mais econômica.

- Criando formas complexas: Excelente para produzir geometrias complexas, como peças em formato de S, U e poligonais, proporcionando flexibilidade para vários requisitos de design e fabricação.

- Manutenção de configuração e ferramentas simples: Projetada para fácil configuração e trocas rápidas de ferramentas, uma pequena prensa dobradeira CNC permite uma troca eficiente entre diferentes aplicações, suportando uma ampla gama de tarefas de dobra.

- Facilitando o movimento fácil: Quando é necessária flexibilidade no posicionamento da máquina, o tamanho compacto de uma pequena prensa dobradeira CNC permite que ela seja facilmente movida por empilhadeira, acomodando mudanças no layout da oficina ou nas necessidades de produção.

Incorporar uma pequena prensa dobradeira CNC em sua oficina pode aumentar sua capacidade de executar diversas tarefas de dobra com precisão, eficiência e custo-benefício, tornando-a uma adição valiosa às suas capacidades de fabricação.

Manutenção de uma pequena prensa dobradeira CNC

Quando se trata de usar e manter uma pequena prensa dobradeira, há algumas dicas importantes que podem ajudar a garantir sua longevidade e desempenho ideal. Aqui estão algumas considerações importantes para ter em mente:

- Leia o Manual: Antes de operar a prensa dobradeira, é crucial ler atentamente o manual do usuário. Isso fornecerá informações valiosas sobre precauções de segurança, procedimentos operacionais e diretrizes de manutenção específicas para sua máquina.

- Pratique a operação segura: Sempre priorize a segurança ao usar uma prensa dobradeira. Use equipamento de proteção adequado, como luvas e óculos de segurança, e certifique-se de que a máquina esteja devidamente aterrada. Familiarize-se com o botão de parada de emergência e outros recursos de segurança, e nunca exceda a capacidade máxima da máquina.

- Manutenção regular: Uma prensa dobradeira bem conservada não só aumentará sua vida útil, mas também melhorará seu desempenho. Inspecione e limpe a máquina regularmente, prestando atenção às ferramentas, ao sistema hidráulico e aos componentes elétricos. Lubrifique as peças móveis de acordo com as recomendações do fabricante e trate prontamente de quaisquer problemas ou anormalidades.

- Manutenção de ferramentas: As ferramentas em uma prensa dobradeira são submetidas a desgaste significativo durante o uso. Verifique regularmente a condição das ferramentas e substitua quaisquer peças desgastadas ou danificadas. Armazenar e organizar adequadamente as ferramentas também é essencial para garantir sua longevidade e fácil acessibilidade.

- Calibração e Alinhamento: Verifique periodicamente a calibração e o alinhamento do freio de prensa para garantir resultados de dobra precisos. Use ferramentas de medição de precisão para verificar o paralelismo do aríete e da cama, bem como os ângulos das dobras. Se alguma discrepância for encontrada, consulte o manual do usuário ou entre em contato com um profissional para obter assistência.

Lembre-se, o uso e a manutenção adequados de uma pequena prensa dobradeira são vitais para o desempenho e a longevidade ideais. Seguindo essas dicas, você pode garantir que sua máquina opere com segurança e eficiência, permitindo que você alcance resultados de dobra precisos e consistentes.

Resumo

Escolher a pequena prensa dobradeira CNC certa é crucial para obter uma dobra de metal eficiente e precisa. Ao avaliar fatores como tamanho, capacidade, recursos, controles, facilidade de uso, durabilidade, confiabilidade e preço, você pode tomar uma decisão informada que se alinhe com seus requisitos específicos. A KRRASS oferece uma gama de pequenas prensas dobradeiras CNC projetadas para fornecer desempenho e versatilidade excepcionais, tornando-as ideais tanto para oficinas de pequena escala quanto para ambientes de fabricação maiores.