Оглавление

Введение

The гибочный пресс — широко используемый в производстве листового металла станок, предназначенный для гибки и формовки металлических листов.

Его цель — обеспечить точную гибку различных металлов (например, стали, нержавеющей стали).

И он широко используется во многих областях, таких как автомобилестроение, аэрокосмическая промышленность, архитектура и производство.

Крайне важно правильно установить листогибочный пресс. Правильно установленная машина может не только обеспечить качество и точность, но и безопасность операторов.

Однако, если гибочный пресс неправильно установлен, это может привести к нежелательным результатам изгиба, стать причиной повреждения машины и создать потенциальные риски для операторов и машин.

В нашем отрывке мы рассмотрим весь процесс установки листогибочного пресса. Сначала посмотрите видео.

Установка листогибочного пресса

Подготовка перед установкой

Выберите место: выберите подходящее место для размещения листогибочного пресса, которое может обеспечить устойчивость и безопасность. Место облегчает работу операторам, а также удобно для обслуживания и ухода.

Обеспечьте надлежащие основания: листогибочный пресс должен быть установлен на прочном основании, чтобы обеспечить точность и устойчивость. Основанием может быть бетонный пол или специально разработанная рама. Основание должно быть достаточно прочным и надежным, чтобы выдерживать вибрацию и рабочую нагрузку машины.

Проверьте требования к электричеству: обычно листогибочный пресс нуждается в электропитании для привода двигателя и контроллера. Перед установкой убедитесь, что электропитание доступно для удовлетворения требований к электричеству. Это может быть связано с сотрудничеством по производству электроэнергии для обеспечения стабильной работы машины.

Подготовлены инструменты и оборудование:

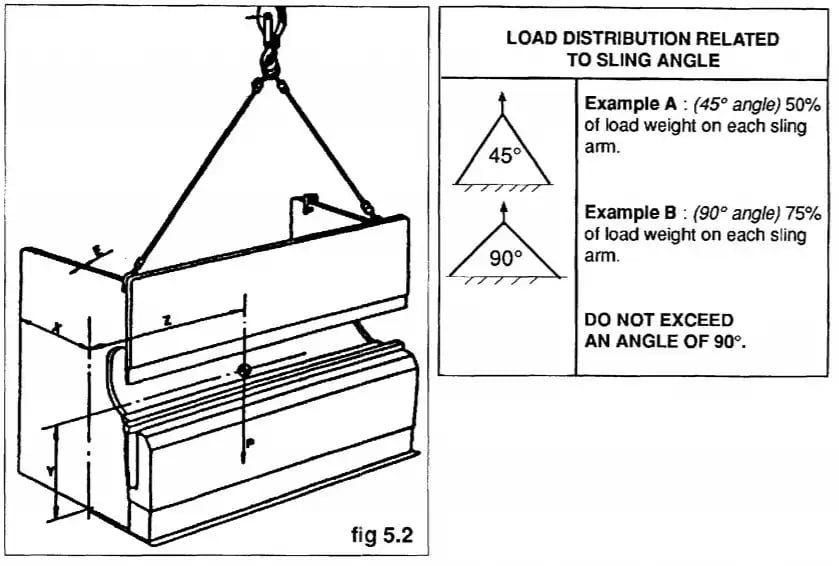

кран или погрузчик незаменимы для работы и поиска крупногабаритных металлических листов и аксессуаров. Гаечный ключ, отвертка и другие инструменты могут помочь операторам быстро и эффективно выполнять плановое обслуживание, устранять мелкие неполадки и вносить необходимые корректировки. Точный спиртовой инструмент и линейки также необходимы для проверки точности и аккуратности.

Позиционирование

Используйте вилочный погрузчик или кран, чтобы установить листогибочный пресс на предварительно подготовленном основании. Убедитесь, что он находится на правильном месте и находится в центре основания.

Распаковка

Проверьте на наличие видимых повреждений или отсутствующих частей: после безопасной разгрузки листогибочного пресса проверьте на наличие вмятин, царапин или других признаков физического повреждения. Крайне важно зафиксировать все поврежденные или утерянные части и сообщить о них производителям и поставщикам.

Снимите окрашенную поверхность или транспортировочные кронштейны: перед эксплуатацией листогибочного пресса снимите эти окрашенные поверхности и необходимые полки. Пожалуйста, следуйте инструкциям производителя и узнайте, как защитить компоненты и инструменты.

Конкретные шаги

Шаг 1: установка основания

В соответствии с моделью и техническими характеристиками листогибочного пресса установите основание в правильное положение, затем закрепите основание на земле с помощью болта или другого фиксирующего приспособления.

Шаг 2: установка колонн

Установите колонны на основание. Колонны обычно состоят из двух или более компонентов. Установите и соберите в соответствии с руководством по эксплуатации. Используйте болты или другие принадлежности, чтобы закрепить колонны на основании, обеспечив его вертикальность и устойчивость.

Шаг 3: установка балки

Установите балку на колонну. Балка состоит из одной или нескольких секций балки. Правильная установка балки соответствует руководству по эксплуатации. Используйте болты или другие фиксированные детали, чтобы закрепить балку на колонне, обеспечив ее горизонтальность и устойчивость.

Шаг 4: установка верстака

Установите рабочий стол на основание и убедитесь, что он выровнен с основанием.

Шаг 5: установка оперативной памяти

Установите толкатель на верстак и с помощью болта отрегулируйте его по высоте и положению.

Шаг 6: установка верхнего пуансона

Установите верхний пуансон на толкатель и надежно закрепите его с помощью болтов и других деталей.

Шаг 7: установка нижней матрицы

Установите нижнюю матрицу на верстак и надежно закрепите ее с помощью болтов и других деталей.

Шаг 8: установка гидравлической системы

Установите гидравлический насос: согласно рекомендациям производителя, установите гидравлический насос в правильном положении листогибочного пресса. Обычно гидравлический насос может быть закреплен на станке с помощью болтов. Соедините вход и выход масла гидравлического насоса, чтобы обеспечить надежное соединение.

Установите гидравлический цилиндр: обеспечьте положение гидравлического цилиндра в соответствии с чертежами конструкции и закрепите цилиндр на листогибочном прессе болтами. Соедините вход и выход масла гидравлического цилиндра, чтобы обеспечить надежное соединение.

Установите гидравлический клапан и контроллер: обеспечьте монтажное положение гидравлического клапана и контроллера на основе чертежа конструкции и закрепите их болтами в соответствующем положении. Соедините впуск и выпуск масла гидравлического клапана и контроллера, чтобы обеспечить надежное соединение.

Установите гидравлический бак и фильтр: правильно установите гидравлический бак и закрепите его болтами. Подключите гидравлический бак и фильтр и убедитесь в их прочном соединении.

Установите гидравлический трубопровод: на основе чертежа конструкции и руководства производителя установите гидравлический трубопровод и подключите гидравлические компоненты и трубопровод. Убедитесь, что гидравлический трубопровод надежно подключен без утечек, и правильно смонтируйте трубопровод, закрепите зажим.

Заполните гидравлическое масло: в соответствии с правилами производителя выберите подходящее гидравлическое масло и залейте масло в бак до достижения требуемого уровня масла. Запустите гидравлическую систему, выпустите воздух и проверьте, работает ли гидравлическая система нормально или нет.

Шаг 9: подключение электрической системы.

Подключите электрическую систему и источник питания и убедитесь, что линия электропередач прочна и надежна.

Подключение к сети электропитания: подключите линию электропитания к соответствующей розетке или выключателю. Убедитесь, что соединение надежное, и используйте соответствующий электрический разъем.

Подключение панели управления: подключите электрические компоненты на панели управления к основному источнику питания машины. Это включает подключение контроллера, кнопок, индикаторных ламп и электрических клапанов к соответствующей силовой проводке и клеммным колодкам.

Подключение двигателя: подключите электроприводной двигатель к основному источнику питания и контроллеру. Обычно это касается подключения силовых и управляющих проводов к соответствующим клеммам.

Подключения датчика и концевого выключателя: листогибочный пресс оснащен датчиком и концевым выключателем, которые используются для тестирования и управления процессом гибки и могут быть подключены к панели управления и контроллеру.

Заземляющее соединение: обеспечьте хорошее соединение между металлической частью листогибочного пресса и заземлением электрической системы. Это направлено на обеспечение безопасности и защиту от поражения электрическим током и накопления статического электричества.

Тестирование и отладка: после завершения вышеуказанного процесса необходимо провести проверку и отладку. Убедитесь, что все электрические компоненты работают в хорошем состоянии, а панель управления может хорошо управлять гибочным прессом.

Шаг 10: установка системы заднего упора

Проверьте положение установки: обычно задний упор устанавливается на задней части листогибочного пресса для поддержки и позиционирования заготовки, подлежащей гибке.

Установите кронштейн: закрепите кронштейн заднего упора на рабочем столе листогибочного пресса. Убедитесь, что кронштейн устойчив и соединен с конструкцией листогибочного пресса.

Установите опорную планку: опорная планка обычно устанавливается сзади или сбоку листогибочного пресса.

Установите направляющую: убедитесь, что она совмещена с рычагом и опорной планкой, и надежно закрепите их.

Подключите трансмиссию: подключите трансмиссию к контроллеру или мото. Убедитесь, что ее можно перемещать и регулировать в соответствии с ожиданиями. Обычно это включает установку электродвигателей, цепей, шестерен и т. д.

Установите ползунок: установите ползунок на кронштейн заднего упора и убедитесь в его плавном ходе. Может потребоваться использовать регулировочный винт для регулировки положения и высоты ползунка.

Установите систему управления: установите контроллер заднего упора в правильное положение и подключите провод и датчик в соответствии с пояснениями производителя. Убедитесь, что система управления может точно контролировать положение ползунка заднего упора.

Шаг 11: настройка и калибровка

На основании руководства по эксплуатации все компоненты должны быть отрегулированы и откалиброваны, чтобы обеспечить их правильную работу и соответствие требованиям.

Шаг 12: окончательная проверка и передача

Первым этапом окончательной проверки является комплексная проверка установленного листогибочного пресса.

Это включает проверку всех компонентов и их производительности. Операторы должны проверить гидравлическую систему, электрическое соединение, панель управления и другие важные компоненты, чтобы убедиться в их правильной установке без каких-либо повреждений.

При возникновении каких-либо проблем или различий немедленно обратитесь за помощью к менеджеру или производителю, чтобы избежать серьезных проблем в будущем.

Кроме того, запись файлов является неотъемлемой частью процесса передачи.

Кроме того, необходимо обеспечить и организовать планы технического обслуживания и подробную информацию для обеспечения немедленного проведения технического обслуживания.

Шаг 13: техническое обслуживание и устранение неполадок

Обслуживание

Регулярное обслуживание: скопившаяся грязь, пыль и мусор.

Смазка: особое внимание уделите осям, направляющим, гидравлическим компонентам и другим важным деталям.

Проверка компонентов: регулярно проводите визуальный осмотр компонентов машины, заменяйте и ремонтируйте поврежденные детали.

Калибровка и выравнивание: убедитесь, что листогибочный пресс можно правильно откалибровать и выровнять.

Обучение операторов: опытные операторы могут продлить срок службы машины.

Заключение

В заключение следует отметить, что правильная установка листогибочных прессов имеет решающее значение для работы предприятий по обработке листового металла и машиностроению.

Он обеспечивает основу для высокоэффективной и точной гибки и гарантирует ожидаемые результаты, а также снижает потенциальные риски.

Производители могут надежно защитить свои инвестиции, одновременно обеспечивая непревзойденную производительность.