A press brake is a machine tool used in metalworking and fabrication processes to bend and shape sheet metal. It is commonly used in the manufacturing of various metal components and structures. The primary function of a press brake is to apply force to a piece of sheet metal, causing it to deform and bend at a predetermined angle.

Here's a basic overview of how a press brake works:

Setup: The operator sets up the press brake by selecting the appropriate tooling (such as dies and punches) and adjusting the machine settings for the specific bending requirements.

Loading: A flat sheet of metal is placed between the two clamping beams or plates of the press brake.

Clamping: The machine's clamping mechanism holds the sheet metal securely in place to prevent movement during the bending process.

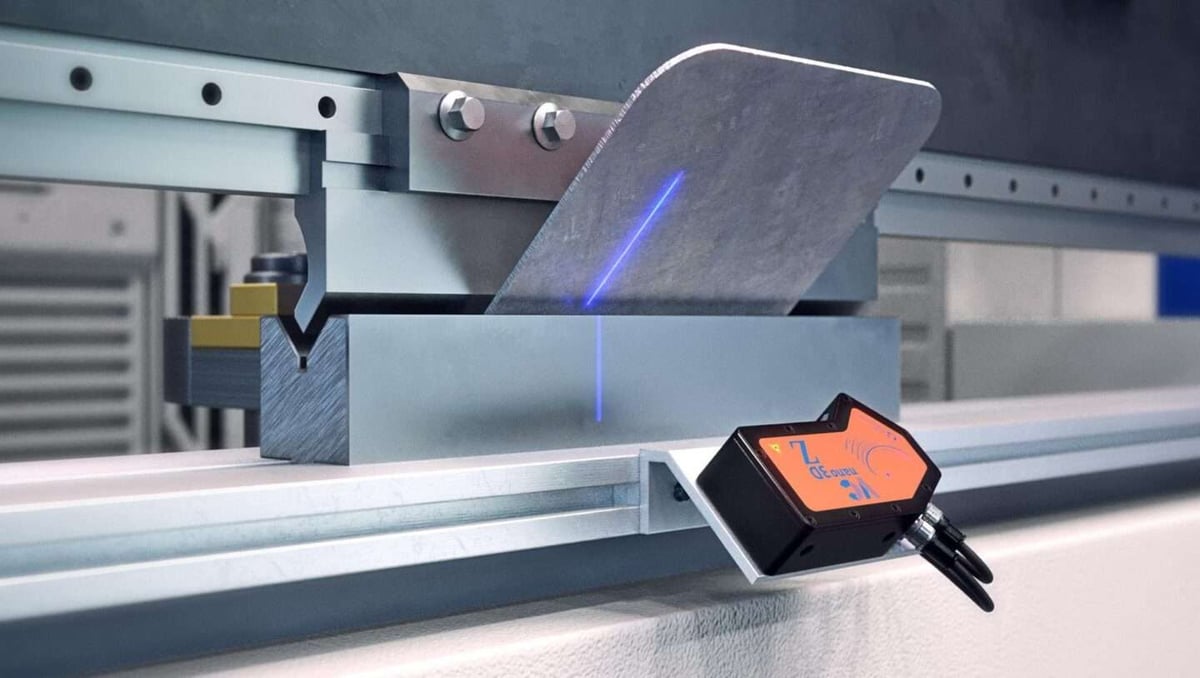

Bending: The press brake exerts a significant amount of force on the sheet metal, causing it to deform and bend according to the chosen angle and tooling setup.

Unloading: Once the bending process is complete, the clamping mechanism is released, and the bent metal is removed from the machine.

Press brakes come in various sizes and capacities, allowing them to handle different thicknesses and lengths of sheet metal. They are essential tools in metal fabrication shops and manufacturing facilities for producing a wide range of components, including brackets, enclosures, panels, and other metal parts with precise bends and shapes. CNC (Computer Numerical Control) technology is often integrated into modern press brakes to automate and control the bending process with high precision and efficiency.

How to maintain the press brake?

Proper maintenance of a press brake is crucial to ensure its longevity, accuracy, and safety. Here are some general guidelines for maintaining a press brake:

Regular Inspections:

Conduct routine visual inspections of the machine to identify any signs of wear, damage, or loose components.

Check for leaks in hydraulic systems, inspect hoses, and replace damaged or worn-out parts promptly.

Lubrication:

Follow the manufacturer's recommendations for lubrication schedules. Regularly lubricate moving parts, bearings, and other critical components to reduce friction and prevent wear.

Ensure that the lubrication points are clean and free from debris.

Cleanliness:

Keep the press brake and its surrounding area clean. Remove dust, chips, and debris regularly to prevent them from affecting the machine's performance.

Clean and inspect the tooling, as dirt and debris on the tools can lead to imperfections in the bends.

Hydraulic System Maintenance:

Check hydraulic fluid levels regularly and top up or replace fluids as needed.

Monitor hydraulic hoses for any signs of wear, leakage, or damage. Replace damaged hoses promptly.

Regularly inspect and clean hydraulic filters.

Electrical System:

Inspect electrical components for signs of wear, damage, or loose connections.

Keep the electrical panels clean and free from dust.

Tooling Inspection:

Regularly check the condition of the tooling, including punches and dies. Replace or sharpen them as necessary to maintain accurate and high-quality bends.

Ensure that the tooling is properly aligned and securely fastened.

Backgauge and Control System:

If your press brake has a backgauge and control system, regularly calibrate and check their accuracy.

Keep the control panel clean and free from dust.

Operator Training:

Train operators on proper machine usage, including safety procedures and basic maintenance tasks.

Encourage operators to report any unusual sounds, vibrations, or issues with the machine promptly.

Alignments and Adjustments:

Periodically check and adjust the alignment of the press brake to ensure accurate and consistent bends.

Verify the parallelism of the clamping beams and the accuracy of the backgauge.

Record Keeping:

Maintain a maintenance log to record inspections, lubrication schedules, repairs, and any other relevant information.

Always refer to the manufacturer's guidelines and documentation for specific maintenance requirements for your press brake model. Additionally, consider scheduling professional inspections and maintenance services periodically to address more complex tasks and ensure the optimal performance of the press brake.

Choice of press brake tools?

The choice of press brake tools, also known as punches and dies, is crucial for achieving accurate and high-quality bends in sheet metal. The selection depends on various factors, including the material being processed, the desired bend angle, sheet thickness, and the specific application. Here are some considerations for choosing press brake tools:

Material Type:

Different materials have varying properties, such as hardness and ductility. Consider the material type (e.g., mild steel, stainless steel, aluminum) when choosing tooling to ensure compatibility and optimal performance.

Bend Radius and Angle:

The bend radius and angle required for your application will influence the choice of tooling. Different punch and die configurations are available to achieve specific bend radii and angles.

Sheet Thickness:

The thickness of the sheet metal being bent is a critical factor. Tooling with the right capacity should be chosen to handle the required thickness without compromising the quality of the bend.

Tooling Style:

Press brake tools come in various styles, including V-dies, hemming tools, radius tools, and more. The choice depends on the specific bending needs of your application.

Tooling Coating:

Some tooling features coatings or surface treatments designed to reduce friction, prevent galling, and extend the tool life. Consider coatings like nitriding or coatings with low friction properties for improved performance.

Material Hardness:

Tooling materials with higher hardness are generally more wear-resistant and suitable for processing harder materials. Consider the hardness of the tooling material based on the hardness of the sheet metal being bent.

Multi-V Die Sets:

Multi-V die sets allow for versatility in bending various angles and radii without changing the tooling frequently. They are useful for applications with diverse bending requirements.

Precision and Tolerance Requirements:

If your application requires high precision and tight tolerances, select tooling that meets these requirements. Precision-ground tooling helps achieve consistent and accurate bends.

Tooling Compatibility:

Ensure that the chosen press brake tools are compatible with your specific press brake model and design. Check for tooling standards like European (Promecam/Amada) or American (Trumpf) style.

Specialized Tooling:

For unique or specialized applications, consider using custom or specialized tooling designed to meet specific bending challenges.

It's essential to consult the press brake manufacturer's guidelines and recommendations for tooling selection. Additionally, experienced operators and tooling specialists can provide valuable insights into choosing the right tools based on their knowledge of the application and material characteristics. Regularly inspect and maintain press brake tools to ensure optimal performance and longevity.