Table of Contents

Introduction

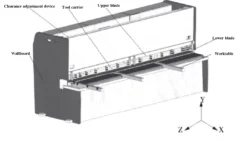

A guillotine shearing machine, also known as a power shear or squaring shear, is a type of industrial machinery designed to cut sheet metal with high precision and efficiency. It consists of a shear blade, mounted on a mechanical or hydraulic mechanism, that moves vertically to apply force and cut through the metal sheet. The cutting process is similar to that of a guillotine, hence the name.

Guillotine shearing machines are commonly used in metal fabrication and manufacturing processes to cut various types of sheet metal, including steel, aluminum, and stainless steel. They are capable of producing clean, straight cuts with minimal distortion, making them essential equipment in industries such as automotive, aerospace, construction, and metalworking.

These machines come in different sizes and configurations to accommodate a wide range of sheet metal sizes and thicknesses. Some guillotine shearing machines are manually operated, while others feature automated controls and programmable settings for enhanced precision and productivity.

Overall, guillotine shearing machines play a crucial role in the metalworking industry by providing efficient and accurate cutting solutions for various applications.

Principle of Guillotine Shearing Machine

Hydraulic guillotine shears are highly efficient machines that utilize a hydraulic system to generate immense force, enabling the movement of the upper blade to cut through various materials. With precise control over the applied force, these shears ensure clean and accurate cuts for a wide range of materials, from thin sheets to thick plates.

The working principle of hydraulic guillotine shears revolves around the hydraulic system’s ability to generate and control force. The system consists of a pump, cylinders, valves, and other components that work together to transmit power and create the required cutting force.

When the operator initiates the cutting process, the hydraulic pump activates, generating pressure and forcing hydraulic fluid into the cylinders. The hydraulic fluid acts upon the pistons inside the cylinders, pushing them to move the upper blade downward with tremendous force. Simultaneously, the lower blade remains fixed in position.

The controlled application of force ensures that the upper blade accurately contacts the lower blade, tightly gripping the material to be cut. This stable and secure cutting position, coupled with the immense force generated by the hydraulic system, allows the shears to slice through the workpiece effortlessly.

Guillotine shears: Unparalleled Advantages

One of the key advantages of hydraulic guillotine shears is their ability to handle various materials efficiently. Whether it’s mild steel, stainless steel, aluminum, or other metals, these shears can handle different thicknesses with ease. The hydraulic system’s adjustable force allows operators to adapt the shear’s settings to match the specific material and thickness being processed.

Furthermore, hydraulic guillotine shears offer enhanced precision and repeatability. The controlled force application minimizes material deformation, resulting in clean and accurate cuts. This characteristic is vital for industries such as metal fabrication, where precise cutting is crucial to maintaining product quality and minimizing waste.

In addition to their cutting capabilities, hydraulic guillotine shears often come equipped with advanced features for enhanced safety and efficiency. These may include programmable back gauges, digital displays, stroke length adjustment, and automatic blade gap adjustment. Such features contribute to improved productivity and operator convenience.

In conclusion, hydraulic guillotine shears are highly efficient machines that leverage the power of hydraulic systems to deliver precise and clean cutting operations. With their ability to handle various materials and thicknesses, these shears find applications in numerous industries. By combining power, control, and safety features, they offer a reliable solution for businesses seeking efficient and precise cutting processes.

Advantages of Guillotine Shearing Machine Compared to Swing Beam Shearing Machine

Guillotine shearing machines and swing beam shearing machines are two common types of equipment used in metal fabrication for cutting sheet metal. While both serve the same fundamental purpose, they differ in their mechanisms and operation. Here are some advantages of guillotine shearing machines compared to swing beam shearing machines:

- Straight Cutting: Guillotine shearing machines typically offer straighter cuts compared to swing beam shearing machines. The vertical motion of the shear blade in a guillotine machine allows for precise, linear cuts across the entire length of the metal sheet, resulting in clean and accurate edges.

- Higher Cutting Capacity: Guillotine shearing machines are often capable of handling thicker and tougher materials than swing beam shearing machines. This is because the guillotine design allows for greater force to be exerted on the metal sheet, enabling it to cut through heavier gauges with ease.

- Faster Cutting Speed: Due to their design and mechanics, guillotine shearing machines can achieve higher cutting speeds compared to swing beam shearing machines. The vertical motion of the blade in a guillotine machine allows for rapid descent and ascent, resulting in quicker processing times for large volumes of sheet metal.

- Adjustable Cutting Angle: Some guillotine shearing machines offer the flexibility to adjust the cutting angle, allowing operators to optimize the cutting process for different materials and thicknesses. This feature enhances versatility and precision in various metalworking applications.

- Ease of Maintenance: Guillotine shearing machines typically have simpler mechanisms and fewer moving parts compared to swing beam shearing machines. This makes them easier to maintain and repair, reducing downtime and associated costs.

- Compact Design: Guillotine shearing machines often have a more compact footprint compared to swing beam shearing machines of similar cutting capacity. This makes them suitable for smaller workshops or manufacturing facilities with limited space.

While guillotine shearing machines offer several advantages over swing beam shearing machines, the choice between the two ultimately depends on factors such as the specific requirements of the application, the type of materials being processed, and budget considerations.

Cost of Gate Shears

The cost of gate shears can vary significantly depending on several factors such as the brand, size, capacity, features, and where you purchase them from. Generally, smaller manual gate shears designed for light-duty cutting tasks may range from $100 to $500 USD.

However, larger, motorized gate shears capable of handling heavy-duty industrial applications can cost anywhere from $1,000 to $10,000 USD or more. Additionally, specialized gate shears with advanced features or customizations may have higher price points. It's essential to consider your specific requirements and budget when evaluating the cost of gate shears.

Choose Krrass, Make Formed Decison

When it comes to selecting the right equipment for your metal fabrication needs, choosing Krrass ensures you're making an informed decision backed by years of expertise and innovation. With a commitment to quality, reliability, and customer satisfaction, Krrass provides a comprehensive range of machinery solutions designed to meet the diverse needs of modern manufacturing.

Whether it's shearing machines, press brakes, or laser cutting equipment, Krrass delivers cutting-edge technology and exceptional performance to help you achieve your production goals. Choose Krrass for precision, efficiency, and excellence in metal fabrication.