Table of Contents

Development of Laser Cutting

The development of laser cutting technology has been a significant advancement in manufacturing and fabrication processes. Here's a brief overview of the key stages in the development of laser cutting:

Invention of the Laser (1960s): The concept of the laser (Light Amplification by Stimulated Emission of Radiation) was first proposed by scientists in the 1950s, and the first working laser was developed in 1960. This groundbreaking invention paved the way for numerous applications, including laser cutting.

Early Experiments (1960s-1970s): In the early years of laser technology, researchers conducted experiments to explore its potential applications. Early laser cutting experiments involved using CO2 lasers to cut materials such as metals, plastics, and fabrics.

Industrial Adoption (1980s): By the 1980s, advancements in laser technology led to the commercialization of laser cutting systems for industrial applications. CO2 lasers emerged as the preferred choice for industrial laser cutting due to their ability to cut a wide range of materials with high precision and efficiency.

Advancements in Laser Technology (1990s-2000s): Throughout the 1990s and 2000s, significant advancements were made in laser technology, leading to improvements in cutting speed, accuracy, and versatility. Fiber lasers, which use optical fibers to generate laser beams, emerged as an alternative to CO2 lasers, offering advantages such as higher cutting speeds and lower operating costs.

Integration of CNC Technology: The integration of computer numerical control (CNC) technology with laser cutting systems revolutionized the industry. CNC controllers enabled precise control over the cutting process, allowing for complex shapes and designs to be cut with ease.

Diversification of Applications: As laser cutting technology matured, its applications diversified across various industries, including automotive, aerospace, electronics, medical devices, and architectural design. Laser cutting became the preferred method for cutting intricate patterns, contours, and prototypes in these industries.

Advancements in Automation and Robotics: In recent years, there has been a trend towards automation and integration of robotics in laser cutting systems. Automated material handling, part sorting, and robotic loading and unloading have further enhanced productivity and efficiency in laser cutting operations.

Emerging Trends: Looking ahead, ongoing research and development efforts continue to drive innovation in laser cutting technology. Emerging trends include the development of hybrid laser cutting systems, additive manufacturing using laser deposition, and advancements in laser sources and optics for improved cutting performance.

What is Laser Cutting and How It Works

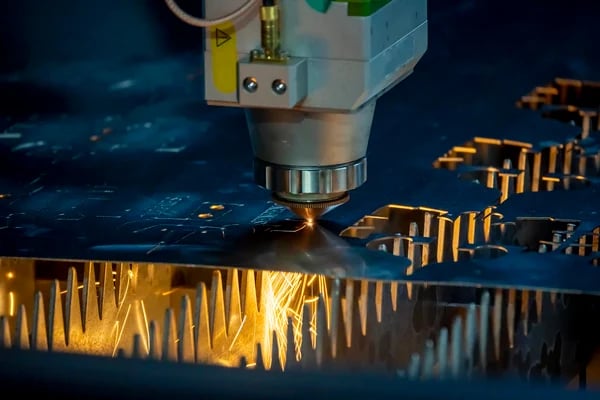

Laser cutting uses a high-power laser which is directed through optics and computer numerical control (CNC) to direct the beam or material. Typically, the process uses a motion control system to follow a CNC or G-code of the pattern that is to be cut onto the material. The focused laser beam burns, melts, vaporises or is blown away by a jet of gas to leave a high-quality surface finished edge.

The laser beam is created by the stimulation of lasing materials through electrical discharges or lamps inside a closed container. The lasing material is amplified by being reflected internally via a partial mirror until its energy is enough for it to escape as a stream of coherent monochromatic light. This light is focused at the work area by mirrors or fibre optics that direct the beam through a lens which intensifies it.

At its narrowest point, a laser beam is typically under 0.0125 inches (0.32 mm) in diameter, but kerf widths as small as 0.004 inches (0.10mm) are possible depending on material thickness.

Where the laser cutting process needs to start anywhere other than the edge of the material, a piercing process is used, whereby a high power pulsed laser makes a hole in the material, for example taking 5-15 seconds to burn through a 0.5-inch-thick (13 mm) stainless steel sheet.

Laser cutting uses a high-power laser which is directed through optics and computer numerical control (CNC) to direct the beam or material. Typically, the process uses a motion control system to follow a CNC or G-code of the pattern that is to be cut onto the material. The focused laser beam burns, melts, vaporises or is blown away by a jet of gas to leave a high-quality surface finished edge.

The laser beam is created by the stimulation of lasing materials through electrical discharges or lamps inside a closed container. The lasing material is amplified by being reflected internally via a partial mirror until its energy is enough for it to escape as a stream of coherent monochromatic light. This light is focused at the work area by mirrors or fibre optics that direct the beam through a lens which intensifies it.

At its narrowest point, a laser beam is typically under 0.0125 inches (0.32 mm) in diameter, but kerf widths as small as 0.004 inches (0.10mm) are possible depending on material thickness.

Where the laser cutting process needs to start anywhere other than the edge of the material, a piercing process is used, whereby a high power pulsed laser makes a hole in the material, for example taking 5-15 seconds to burn through a 0.5-inch-thick (13 mm) stainless steel sheet.

Type of Laser Cutting

This process can be broken down into three main techniques - CO2 laser (for cutting, boring, and engraving), and neodymium (Nd) and neodymium yttrium-aluminium-garnet (Nd:YAG), which are identical in style, with Nd being used for high energy, low repetition boring and Nd:YAG used for very high-power boring and engraving.

All types of lasers can be used for welding.

CO2 lasers involve the passing of a current through a gas mix (DC-excited) or, more popularly these days, using the newer technique of radio frequency energy (RF-excited). The RF method has external electrodes and thereby avoids problems related to electrode erosion and plating of the electrode material on glassware and optics that can occur with DC, which uses an electrode inside the cavity.

Another factor that can affect laser performance is the type of gas flow. Common variants of CO2 laser include fast axial flow, slow axial flow, transverse flow, and slab. Fast axial flow uses a mixture of carbon dioxide, helium and nitrogen circulated at a high velocity by a turbine or blower. Transverse flow lasers use a simple blower to circulate the gas mix at a lower velocity, while slab or diffusion resonators use a static gas field which requires no pressurisation or glassware.

Different techniques are also used to cool the laser generator and external optics, depending on the system size and configuration. Waste heat can be transferred directly to the air, but a coolant is commonly used. Water is a frequently used coolant, often circulated through a heat transfer or chiller system.

One example of water cooled laser processing is a laser microjet system, which couples a pulsed laser beam with a low-pressure water jet to guide the beam in the same manner as an optical fibre. The water also offers the advantage of removing debris and cooling the material, while other advantages over ‘dry’ laser cutting include high dicing speeds, parallel kerf, and omnidirectional cutting.

Fibre lasers are also gaining popularity in the metal cutting industry. This technology uses a solid gain medium rather than a liquid or gas. The laser is amplified in a glass fibre to produce a far smaller spot size than that achieved with CO2 techniques, making it ideal for cutting reflective metals.

Advantages of laser cutting include:

Precision: Laser cutting offers high levels of accuracy and repeatability, making it ideal for producing intricate and complex shapes with tight tolerances.

Versatility: Laser cutting can be used on a wide variety of materials, including metals, plastics, wood, and more.

Speed: Laser cutting is a fast and efficient process, allowing for rapid production of parts and components.

Minimal Material Waste: Laser cutting produces narrow kerfs, resulting in minimal material waste and higher material utilization.

Clean Edges: Laser cutting produces clean, smooth edges without the need for secondary finishing processes.

Non-contact Cutting: Since the laser beam does not physically touch the material, there is minimal risk of damage or deformation to the workpiece.

Automation: Laser cutting systems can be easily integrated with automation and robotics for increased productivity and efficiency.