What is Press Brake K Factor

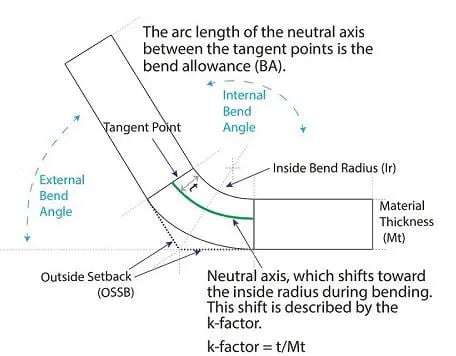

The press brake K-factor, also known as the bend allowance factor, is a dimensionless parameter used in sheet metal bending to determine the amount of material elongation that occurs during the bending process. It helps calculate the bend allowance, which is the extra material length required for bending.

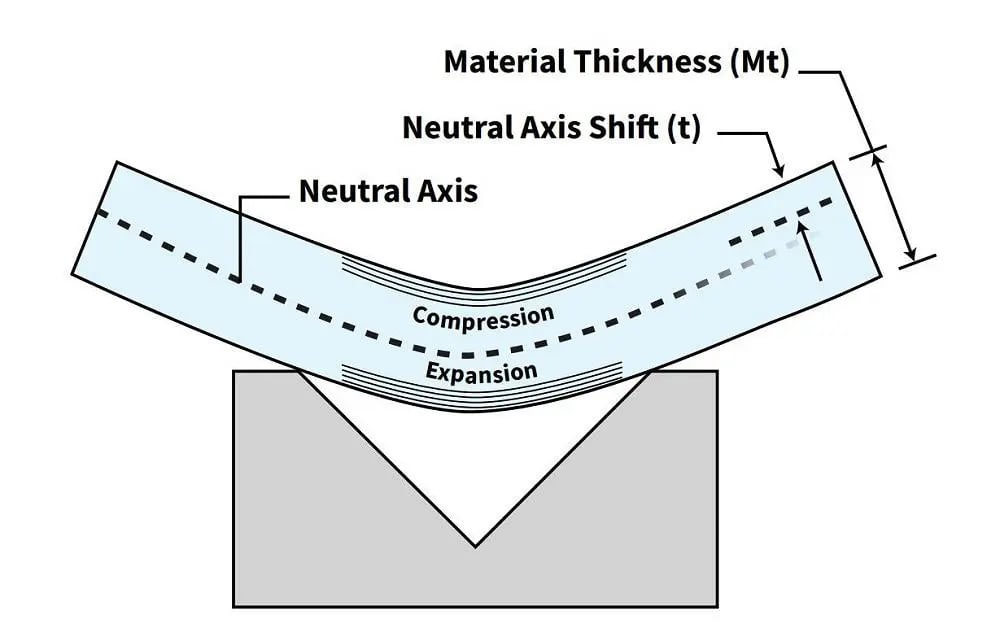

The K-factor accounts for the material thickness, bend radius, and the characteristics of the material being bent. It essentially represents the ratio between the distance from the inside radius of the bend to the neutral axis of the material and the material thickness.

A lower K-factor indicates less material stretching during bending, while a higher K-factor indicates more stretching. The K-factor is essential for accurately predicting the final bend angle and achieving precise bend dimensions in sheet metal fabrication.

Determining the correct K-factor for a specific material and bending setup often requires experimentation or referencing material specifications. It can vary based on factors such as material type, thickness, tooling, and bending method. Once determined, the K-factor is typically used in bend allowance formulas to calculate the amount of material elongation and achieve accurate bend dimensions.

Bending a Test Piece

Reverse engineering the k-factor for press brake is the only way to determine its actual value, or at least one as close to perfect as possible. You can do this by running test bends, measuring the results, and extracting the k-factor from the BA formula that incorporates the results you measured. It might be your best option, especially if you’re creating a table.

But—and this is a big but—you also need to consider the material tolerances, including tensile, yield, and thickness. You could end up with some very precise k-factor data from a test piece, but the test piece material might not match the properties of the material you bend in production. Regardless, if you have just found the BA by bending test pieces, you might not need the k-factor anyway.

Calculating the K-Factor, No Test Piece Required

There is another way to calculate the k-factor without bending any test pieces. It’s not perfect, but then again, neither is bending a test piece. Not only can material properties change, but so can the exact properties of the tooling you use (differing amounts of friction) and different methods of forming.

Illustration showing k-factor in sheet metal bending

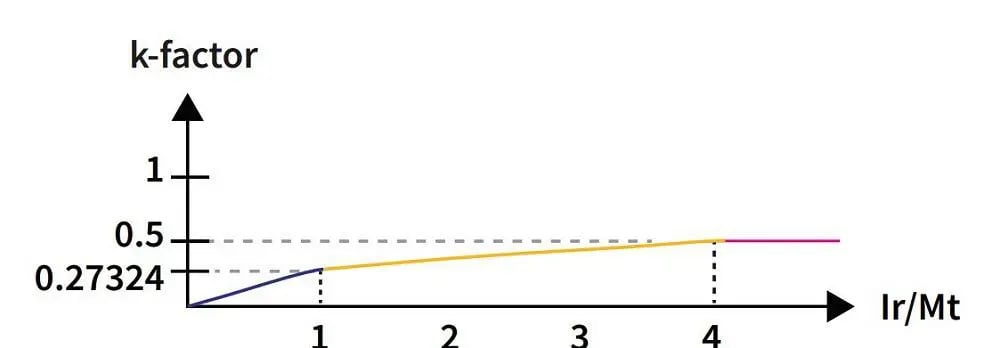

FIGURE 1. The k-factor, expressed as t/Mt, is a ratio that describes the neutral axis’s shift inward during bending.

With all that said, you can start by graphing the k-factor, as shown in Figure 3. This shows the maximum value for the k-factor at 50% of the material thickness, noted by the red line. Where the yellow and red lines meet (point 4 in the chart) represents an inside bend radius equal to four times the material thickness. Above that, you will calculate factors larger than 50%, but you shouldn’t use them. As the chart shows, you need to maintain your k-factor at that maximum 0.50 value.

Location 1 on the chart, where the blue and yellow lines meet, is the k-factor value for a sharp or minimum producible inside radius for an air form. Any value below this puts the bend into an area that exceeds the physical limits of compressibility—at least for our baseline, mild steel material. As I have stated many times before, sharp bends are the bane of air forming accuracy.

The minimum k-factor for air forming can be expressed as (4-π)/π, or 0.27324. We subtract that value from our maximum k-factor value of 0.5:

0.5 - 0.27324 = 0.22676

This result gives us our range of possible k-factors as noted on the yellow line on the chart. Next, we divide 0.22676 by 3:

0.2267/3 = 0.07558

This gives us our multiplier—that is, the number we multiply to our bend’s inside radius-to-material thickness ratio. We find that ratio by dividing the inside bend radius by material thickness. I’ll use a 0.093-in. inside bend radius in 0.062-in.-thick material.

0.093/0.062 = 1.5

We then multiply by our multiplier, 0.07558, and add the result to the minimum k-factor of 0.273:

0.07558 × 1.5 = 0.113

Illustration showing k-factor and outside setback in metal bending

FIGURE 2. The k-factor describes the neutral axis’s shift inward during bending. That shift causes the metal to elongate, which we accommodate for in our bend calculations.

0.113 + 0.273 = 0.386

That makes our k-factor 0.386. All this can be summed up in the following formula. Again, you derive the minimum k-factor and multiplier from the chart in Figure 2.

K-factor= [Multiplier × (Inside Radius/Material Thickness)] + Minimum K-factor

Breaking Down the Bend Allowance

You’ve found the k-factor. Now what? What do we do with that number? How is it applied, and why should you care? Why you should care depends on the quality of the product you want to produce. Understanding the k-factor makes a big difference. First, look at your BA formula:

BA = [(0.017453 × Inside Bend Radius) + (0.0078 × Material Thickness)] × Outside Bend Angle

In this equation, 0.017453 is π/180, which converts degrees into radians, or units of measure for angles based on a circle’s radius. We perform this conversion because trigonometric functions in mathematical calculations typically require angles to be in radians rather than degrees. When you multiply the converted angle (in radians) by the radius, you’re essentially calculating the length along the arc of the circle formed by the bend. So, π/180 multiplied by the inside radius represents the arc length along the neutral axis for one degree of angle.

The second part of the equation again begins with the conversion of degrees to radians (π/180), which is then multiplied by a k-factor of 0.4468, giving us the 0.0078 figure in the formula. That represents the compensation that occurs when the neutral axis shifts inward during bending, causing material to elongate and adding length to the part dimensions.

We now know the total length of the arc and the extra length created by the neutral axis shift. Still, until now, we’ve just calculated for one degree of bend angle. Now, we multiply the total external bend angle, as measured from outside of the bend. (Note: Never use the inside bend angle when calculating the BA.)

One Factor Among Many

Note that plenty of variables can mess with your k-factor values, especially if operators choose different die openings or use different methods of forming. So, what is the “best” way to recalculate your k-factor tables? Perhaps it’s an Excel spreadsheet. Perhaps you can bend test pieces. Just know that the k-factor is but one variable among many to consider.