The press brake tooling is a tool used by the bending machine to form and process sheet materials. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. It is a tool used to make the blank into a part with a specific shape and size under the pressure of the bending machine.

Table of Contents

The structure of the press brake tooling

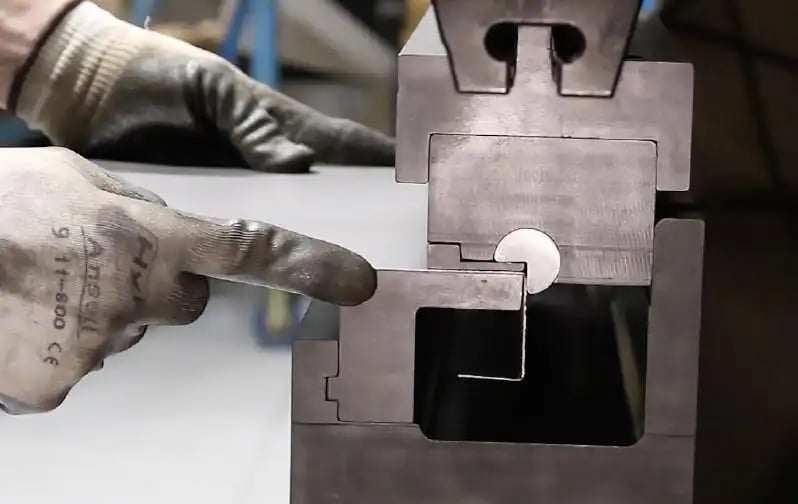

Press brake tooling are divided into the punch and die, which are used for sheet metal stamping forming and separating molds. The mold used for forming has a cavity, and the mold used for separation has a cutting edge.

Material selection

Generally use T8 or T10, T10A, and the better 42CrMo material, it mainly requires high strength, high toughness, and good wear resistance. Cold work dies steel Cr12MoV is a good material. The use performance can be satisfied, and the process performance is good, the price will be higher 42CrMo is a high-strength alloy quenched and tempered steel with high strength and toughness and can work below 500 degrees.

Terms of use

1.Turn on the power of the bending machine, turn the key switch, press the oil pump to start, and the bending machine oil pump starts to rotate. At this time, the machine has not yet started to work.

2.The stroke adjustment requires a trial run when the bending work with the bending machine mold is officially started. When the upper die of the bending machine descends to the bottom, there must be a gap of plate thickness. Otherwise it will cause damage to the mold and the machine. The stroke adjustment also has electric quick adjustment and manual fine adjustment.

3.For the selection of the notch of the bending machine die, a notch of 8 times the width of the plate thickness is generally selected. If you bend a 4mm sheet, you need to choose a slot of about 32.

4.Check the overlap and firmness of the upper and lower molds of the bending machine; check whether each positioning device meets the requirements of being processed. Frequently check the overlap of the upper and lower molds; whether the instructions of the pressure gauge meet the regulations.

5.When the sheet is bent, it must be compacted to prevent the sheet from lifting and hurting the operator during the bending.

6.The power supply must be cut off when adjusting the sheet metal die, and the operation should be stopped.

7.When changing the opening of the lower die of the variable bending machine, no material is allowed to contact the lower die.

8.It is forbidden to use bending machine dies to bend over-thick iron plates or hardened steel plates, high-grade alloy steels, square steels, and sheets that exceed the performance of the sheet metal bending machine to avoid damage to the machine tool.

9.Turn off the bending machine, and place wooden blocks on the lower molds under the cylinders on both sides to lower the upper slide plate onto the wooden blocks. Exit the control system program first, then cut off the power supply.

Installation adjustment

When installing the press brake tooling, be sure to check the status of the equipment, and then install and debug according to the steps, and pay attention to personal safety when debugging.

Machine adjustment: When installing the press brake tooling, you must first understand the performance of the machine, turn on the bending machine, adjust and check patiently, and see if the machine has previously used dust and iron chips. Prevent unnecessary trouble for later use.

Slider stroke adjustment: First check whether the ratio between the thickness of the bending machine mold and the upper and lower modules is normal. The general slider needs to be controlled at the switch point of the stroke line. This must be paid attention to, otherwise, the mold will not be used normally, but some people still make such mistakes often.

Stroke module adjustment: After adjusting the slider stroke standard, the next step is to adjust the upper limit point of the module. Generally speaking, when the module is up to the highest point, the module and switch must be set. In this way, the staying position of the module can be flowed out, and through some of the above operations, the production efficiency can be greatly increased. In this process, the module also needs to be slowed down. Because the module must be decelerated when it is down to the bottom dead center, which protects the machine and the mold.

Adjustment of the gap: Finally, the gap between the molds of the bending machine is adjusted. The gap between the upper module and the lower module is measured first, and the reasonable gap needs to be determined according to the folded plate.

Angle adjustment: Adjusting the bending angle is also the most important link. The angle selection must be related to the product requirements. Generally speaking, when bending a 90° mold, the angle must be set to be greater than the angle between the two sides. Sometimes it may be tight. It can be handled by adjusting the screws on the machine. After the adjustment, if the product does not change the demand, do not modify it again. Then, when bending, use the pressure gauge to calculate the accurate pressure number and adjust the pressure. So as not to cause mold chipping.

Press brake tooling operating procedures

Press brake tooling is divided into manual bending machine molds, hydraulic bending machines, and CNC press brake tooling. Hydraulic press brake toolings can be divided into torsion axis synchronization, machine-hydraulic synchronization, and electro-hydraulic synchronization according to the synchronization method. Hydraulic press brake toolings can be divided into the up-moving type and down-moving type according to the movement mode. Including bracket, workbench, and clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressing plate. The base is connected with the clamping plate through a hinge. The base is composed of a housing, a coil, and a cover, and the coil is placed on the housing. Inside the recess, the top of the recess is covered with a cover plate. Pay attention to the following points during operation:

- Strictly abide by the safe operating procedures of machine tool workers, and wear labor protection equipment as required.

- Before starting, you must carefully check whether the motor, switch, circuit and grounding are normal and firm, and check that the control parts and buttons of the equipment are stuck in the correct position.

- Check the coincidence and firmness of the upper and lower molds; check whether each positioning device meets the requirements of being processed.

- When the upper slide plate and each positioning axis are not at the origin, run the return-to-origin program.

- After the equipment is started, run dry for 1-2 minutes, and move on the slide full stroke 2-3 times. If there is any abnormal sound or malfunction, stop it immediately, remove the malfunction, and stop working until it is normal.

- When working, there should be one person--command, so that the operators and the feeding and suppressing personnel cooperate closely to ensure that the cooperating personnel is in a safe position before issuing the bending signal.

- When the sheet is bent, it must be compacted to prevent the sheet from lifting and hurting people during the bending.

- The power supply must be cut off when adjusting the sheet metal press mold, and proceed after stopping the operation.

- When changing the opening of the variable lower mold, do not allow any material to contact the lower mold.

- When the machine tool is working, no one is allowed to stand behind the machine tool.

- It is strictly forbidden to fold the sheet at one end alone.

- If the workpiece or mold is found to be incorrect during operation, stop and correct it. It is strictly forbidden to correct it by hand to prevent hand injury.

- It is forbidden to fold over-thick iron plates or quenched steel plates, high-grade alloy steels, square steels, and sheets that exceed the performance of the sheet metal bending machine to avoid damage to the machine tool.

- Frequently check the overlap of the upper and lower molds; whether the instructions of the pressure gauge meet the regulations.

- Immediately stop the machine if an abnormality occurs, check the cause, and eliminate it in time.

- Before shutting down, place wooden blocks on the lower molds under the cylinders on both sides to lower the upper slide plate onto the wooden blocks.

- Exit the control system program first, then cut off the power supply.

Application

Equipment manufacturing industry: In the context of the increasingly tight global energy supply and the continuous increase in oil prices, the demand for power generation equipment has become more and more obvious. In the manufacturing process of power generation equipment, the cost only spent on the mold part of the CNC bending machine is very considerable.

Mold manufacturing industry: In the mold manufacturing process, almost all links such as forming molds, hot work molds, cold work molds, and plastic molds need to use CNC bending machine molds. In addition, automobiles, high-speed trains, general machinery manufacturing, and the wood processing industry, which has gradually expanded its use in recent years, have become the main users of the CNC press brake tooling industry.

Aerospace industry: In this industry, CNC press brake toolings are generally used to cut aircraft structural parts. These structural parts are generally relatively large, and aluminum alloys were used in large quantities in the past. With the expansion of application fields of titanium alloys and composite materials, the requirements for mold processing of CNC bending machines are getting higher and higher.

Development trend

From the perspective of the development of CNC press brake toolings, from the end of the nineteenth century to the middle of the twentieth century, high-speed steel was the main representative of the mold materials for CNC bending machines; in 1927, Germany first developed and obtained hard alloy CNC press brake tooling materials. Widely used; in the 1950s, Sweden and the United States synthesized synthetic diamonds respectively, and the cutting CNC bending machine molds have entered a period represented by superhard materials. In the 1970s, people synthesized polycrystalline diamond using high-pressure synthesis technology, which solved the problem of scarcity and high price of natural diamonds and expanded the application range of diamond CNC press brake toolings to aviation, aerospace, automobiles, electronics, and stone. And many other fields.

The choice of die material for CNC bending machines is the basis for the successful cutting process. Compared with cemented carbide, the die speed of the PCD CNC bending machine can reach 4000m/min, while that of cemented carbide is only 1/4. In terms of service life, PCD CNC press brake toolings can generally be increased by 20 times. From the perspective of the processed surface quality, the effect of PCD is 30%-40% better than that of cemented carbide. In addition, the development of CBN (Vertical Boron Nitride) superhard material CNC press brake toolings and surface coating CNC press brake toolings have also contributed to the advancement of cutting technology.

Standard Press Brake Tooling

Press Brake Tooling

Press brake tooling is an essential component of any sheet metal fabrication process. Standard press brake tooling refers to the commonly used punches and dies that are used in the industry. These tools are designed to work with press brakes to shape and form sheet metal into various shapes and sizes. They are available in different sizes and shapes, and each is designed for a specific application. In this article, we will discuss in detail standard press brake tooling, its types, and its applications.

press brake tooling

Introduction to Press Brake Tooling

Press brake tooling refers to the set of punches and dies used in a press brake machine to form and shape sheet metal. The press brake is a machine tool that is used to bend and shape sheet metal into various shapes and sizes. The machine consists of a hydraulic system that applies force to a punch, which then bends the metal over a die. The die has a specific shape that determines the final shape of the metal.

There are two main types of press brake machines: mechanical and hydraulic. Mechanical press brakes use a flywheel and clutch to apply force to the punch. Hydraulic press brakes, on the other hand, use a hydraulic system to apply force. Hydraulic press brakes are more commonly used in the industry because they provide more precise control over the bending process.

Press brake tooling consists of two main components: punches and dies. The punch is the part of the tool that applies force to the metal, while the die is the part that shapes the metal into the desired shape. The punch and die are designed to work together to form the metal into the desired shape.

Types of Press Brake Tooling

Press brake tooling is available in various types, each designed for specific applications. The most commonly used types of press brake tooling include:

V-Dies

V-dies are the most commonly used type of press brake tooling. They are designed to form straight bends in sheet metal. V-dies come in different sizes and angles, depending on the thickness and type of metal being bent. The angle of the V-die determines the bend angle of the metal. The most common angles for V-dies are 60 degrees and 90 degrees.

Bottoming Dies

Bottoming dies, also known as straight dies, are used to form acute angles in sheet metal. They are designed to work with a V-die to form a sharp bend in the metal. The bottoming die is used after the V-die to ensure that the bend is accurate and consistent.

Gooseneck Punches

Gooseneck punches are used to form complex shapes in sheet metal. They have a curved shape that allows them to bend the metal in different directions. Gooseneck punches are used for applications that require multiple bends and shapes.

Urethane Dies

Urethane dies are used to form sheet metal without leaving any marks or scratches. They are made of a soft material that conforms to the shape of the metal being bent. Urethane dies are used for applications that require a high-quality finish.

Radius Dies

Radius dies are used to form curved bends in sheet metal. They come in different sizes and radii, depending on the application. Radius dies are used for applications that require curved bends, such as automotive parts and furniture.

Standard Press Brake Tooling Specifications

Material: Press brake tooling is usually made of high-grade tool steel or a special alloy steel that can withstand the high pressure and wear and tear of bending metal.

Hardness: The hardness of press brake tooling is measured in Rockwell hardness (HRC) and typically ranges from 45 HRC to 65 HRC. The harder the tooling, the longer it will last, but it may also be more brittle and prone to cracking.

Type of Tooling: There are different types of press brake tooling, including V-dies, punches, and dies. V-dies are used for creating bends in sheet metal, while punches and dies are used for creating different shapes and forms in the metal.Height: The height of press brake tooling is usually measured in millimeters or inches and refers to the distance from the bottom of the die to the center of the punch.

Radius: The radius of press brake tooling refers to the size of the bend that can be created with the tooling. The radius is usually measured in millimeters or inches and can vary depending on the specific tooling.

Angle: The angle of press brake tooling refers to the angle at which the punch is mounted. The angle can be straight or beveled, depending on the specific application.

Coatings: Some press brake tooling may be coated with a layer of tungsten carbide or other materials to improve their wear resistance and extend their lifespan.

Summary

Press brake tooling is essential for achieving accurate and consistent bends in sheet metal and other materials. By selecting the appropriate punches, dies, and accessories, operators can produce a wide range of parts with varying bend profiles and dimensions on a press brake machine.