The press brake U bend technique is a key method used in metalworking, particularly in sheet metal fabrication, where a press brake machine is employed to create a "U" shaped bend in a piece of metal. This bending process is crucial for producing parts with specific angles and configurations, often used in industries such as automotive, aerospace, and construction. The press brake U-bend technique offers precision and repeatability, making it a go-to choice for manufacturers looking to create high-quality bends efficiently. In this guide, we’ll explore the step-by-step process, tools, and best practices to achieve optimal results using a press brake for U-bending applications.

How to Understand Press Brake U Bend?

Basics of Press Brake U Bends

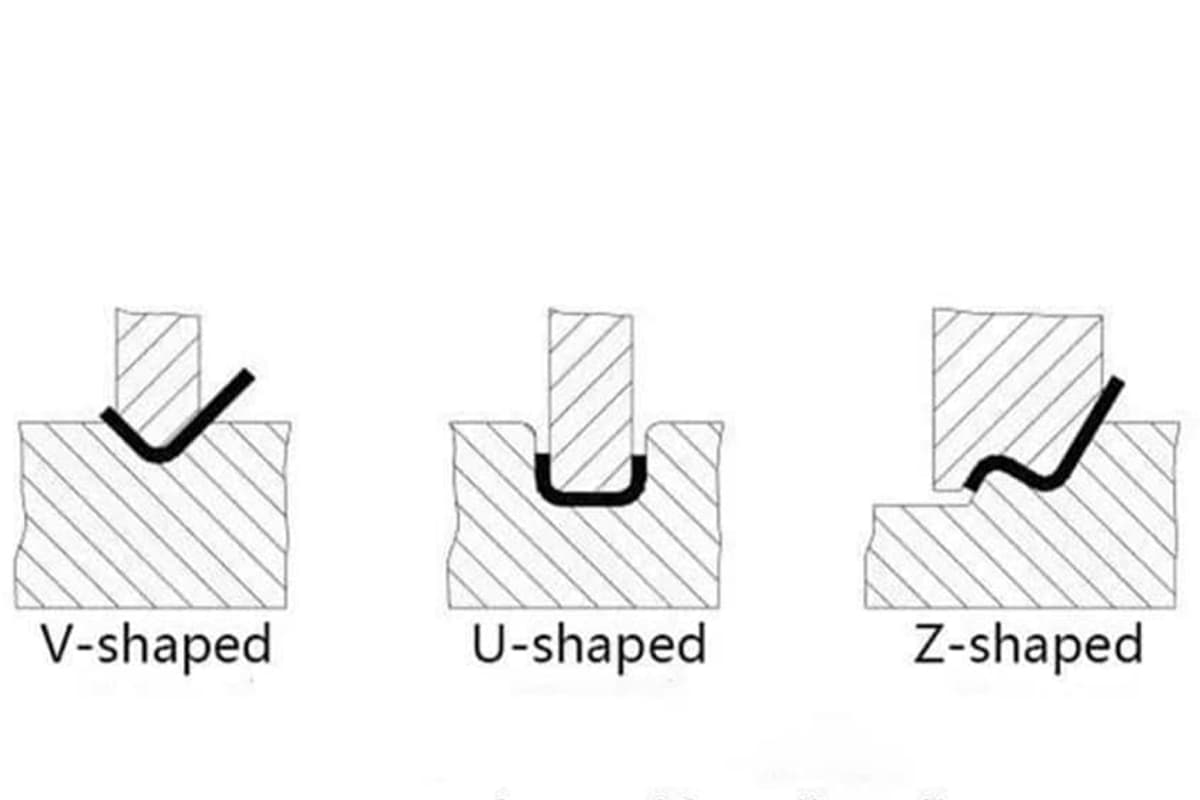

Press brake u bend refers to a process in which the metal sheet will be bent constantly on the press brake twice or more to be formed into the “u” shape.

This process is achieved by accurately controlling the closing degrees of upper and bottom dies and strokes to meet the design requirement's precise size and angle. The u bend is one of the most common forming techniques in metal fabrication industries.

U bend is essential in various industries like metal manufacturing and mechanical engineering. It is widely used in producing architectural and structural parts, automobile parts, home appliance casings, and design manufacturing requiring inner space like piping systems and electrical cabinets.

U bend can not only save material costs and improve production efficiency but also ensure the products' good mechanical properties and appearance quality.

History and Evolution of Press Brake Technology

The press brake is considered a pivotal precision sheet metal forming equipment, and its history can be dated back to early industrialization. The initial manual press brake depends on the labor force, which features complex operation and low efficiency.

With the advancement of technology, hydraulic and CNC technology significantly improve the development of the press brake, making the machine able to proceed with precise and intricate bending, including u bend.

U bend technology is constantly upgraded with the evolution of press brake technology, which ranges from simple straight-line bending to three-dimensional bending. Not only achieving improved apparently bending angle and precision but also realizing multi-step sequence automatic constant bending.

Modern CNC press brakes can even be integrated with CAD/ CAM software, precisely imitating and controlling the overall u bend, achieving high precision and mass production projects. What’s more, the die technique and assistant tools, like the back gauge and front support device, also further enrich and improve the possibility and adaptability of the u-bend.

Technical Aspects

Types of Press Brakes for U Bending

Mechanical Press Brake

Pros: simple structure, high-cost performance, convenient maintenance, intuitive operation, suitable for small scale or occasions requiring less precision.

Cons: it probably can not realize an accurate control under high tonnage owing to its movement ways restrictions. Also, it has lower working efficiency than hydraulic types and is unsuitable for mass-scale and constant production.

Hydraulic Press Brake

Pros: the hydraulic system offers stable and intense pressure, which can be adapted to precise sheet metal bending with multiple thicknesses of materials. It also can be adjusted with no levels in a more extensive range, suitable for mass production and industries requiring high precision.

Cons: the equipment is complex and requires regular maintenance for regular operation. Its initial and later maintenance costs are relatively large.

CNC Press Brakes

- Advantages:

- Programmable control ensures high precision and repeatability.

- Minimizes material wastage, making them cost-effective for large-scale production.

- Ideal for producing detailed components, such as automotive chassis parts.

- Disadvantages:

- High purchase and operational costs due to advanced technology.

- Requires skilled operators for programming and maintenance.

- Not always cost-efficient for low-volume production.

Electric Press Brakes

- Advantages:

- Energy-efficient, resulting in lower operating costs over time.

- Delivers excellent precision and consistent bends.

- Reduced maintenance requirements compared to hydraulic systems.

- Disadvantages:

- Limited capacity for high-tonnage bending, making them unsuitable for heavy-duty applications.

- Higher upfront cost compared to mechanical press brakes.

Hybrid Press Brakes

Hybrid press brakes combine the precision of electric systems with the power of hydraulic mechanisms. These machines are often used in applications requiring moderate tonnage, such as aerospace and automotive component production. They balance energy efficiency and performance, making them a versatile option.

- Advantages:

- Lower energy consumption compared to traditional hydraulic systems.

- Capable of handling a range of material thicknesses.

- Reduced maintenance needs due to hybrid technology.

- Disadvantages:

- Higher complexity increases initial investment and training costs.

- Requires specialized knowledge for operation and maintenance.

Selecting the Right Bending Machine

Choosing the most suitable press brake involves considering the specific requirements of the project, such as material type, sheet thickness, production volume, and budget. For example:

- Hydraulic press brakes are ideal for heavy-duty applications like shipbuilding.

- CNC press brakes excel in high-precision industries like automotive manufacturing.

- Electric press brakes are favored in environmentally conscious operations. Understanding the advantages, limitations, and specific applications of each type ensures an informed decision tailored to production needs.

Materials Suitable for U Bends

Knowing different kinds of metal materials’ physical and mechanical properties is vital in the precise design and implementation of the u-bending process, which is beneficial to avoid product quality problems because of improper use of materials.

Low-carbon steel: it features moderate intensity good plasticity, is easy to bend, and is one of the most common materials for producing u bend.

Stainless steel: it is good, corrosive-resistant, and decorative. It requires precise calculation and control of deformation parameters during bending due to high intensity and spring-back properties.

Aluminum: it has a low density and good electrical and thermal conductivity, making it suitable for light parts. When it is bent, you should take the properties of strong ductility and small elastic modulus into consideration in order to avoid over-rebounding and influencing the product quality.

Copper alloy: it features good electrical conductivity and corrosion resistance. Due to its high solidness, it should be processed with proper dies and process conditions.

Design Considerations for U Bends

Bending radius: it is usually greater than a certain multiple of the material thickness to avoid generating cracks or over-large inner stresses during bending, ensuring the integrity of the workpiece structure.

Bending angle: it determines the final shape of the workpiece. It is calculated according to product design requirements and the spring-back effect, thus compensating and arriving at the anticipated geometric size.

Bending force: it is determined by many factors like material thickness, bending radius, and length. Overly large or small pressure may lead to quality problems. Thus, professional calculation tools and empirical formulas are needed to ensure the proper pressure value.

Factors Influencing U Bending Accuracy

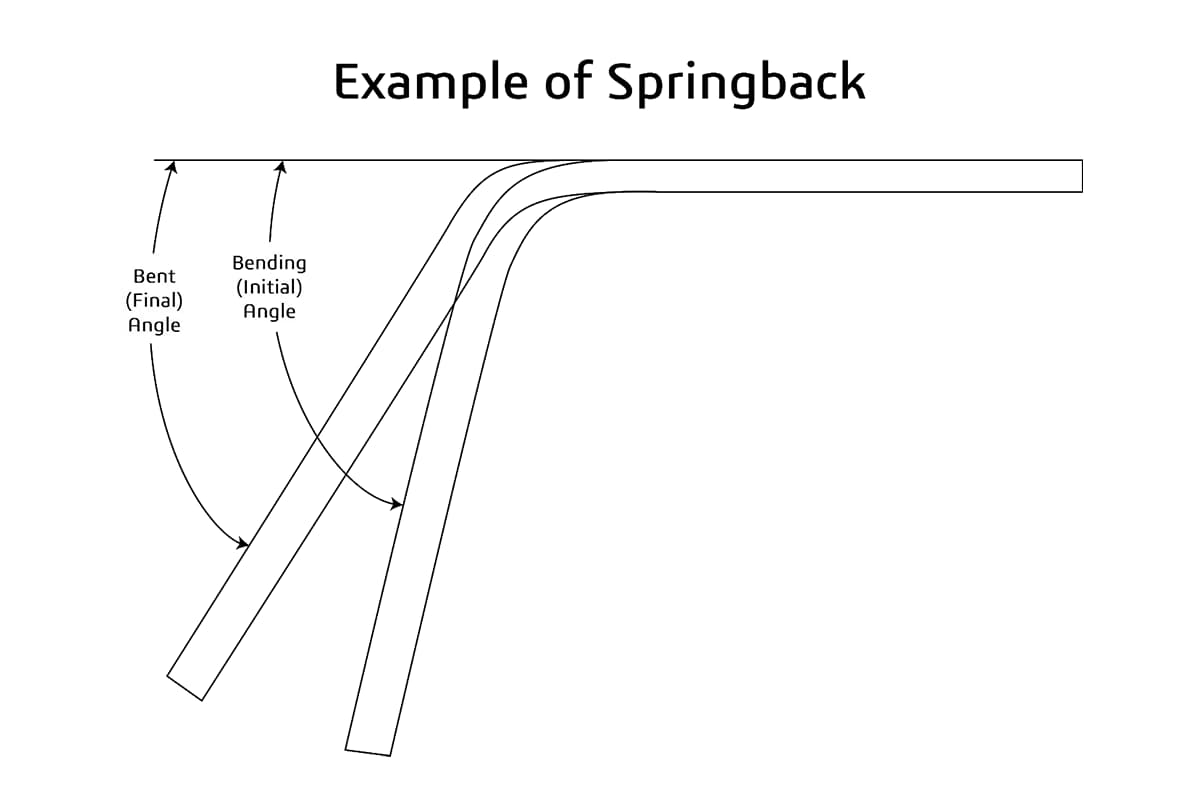

Springback occurs when the metal partially returns to its original shape after bending. To address this, techniques such as overbending, bottoming, and coining are used:

- Overbending applies additional force to counteract springback.

- Bottom bending involves pressing the material into the die to achieve a precise bend.

- Coining creates permanent deformation through high-pressure bending, eliminating material springback.

Material Properties

Material ductility, hardness, and thickness directly affect bending performance. Harder materials may require greater force and careful handling to avoid cracking, while ductile materials allow for smoother bends.

Bend Radius

Maintaining a consistent bend radius is critical for uniform U shapes. The radius depends on the punch nose and die geometry, with tighter radii requiring specialized tooling.

Key Machine Parameters for Precise U Bending

Bending Force

Bending force refers to the amount of pressure the press brake applies, which depends on the material's thickness and strength. It's influenced by factors such as material thickness, bend radius, and the length of the workpiece.

Applying insufficient force may lead to incomplete bends, while excessive force can damage the tooling or material. To ensure accurate bends, the right tool set (punches and dies) must be used to match the force required.

Bending Length

Bending length defines the maximum length of the material that the press brake can handle in a single operation. This is particularly important for large-scale applications, where maintaining uniformity across the entire bend is essential. Longer bending lengths reduce the need for multiple operations, improving both efficiency and consistency.

Cylinder Stroke

The cylinder stroke refers to the vertical movement range of the ram during the bending process. A longer cylinder stroke offers more flexibility for bending thicker or taller materials, accommodating the required bending angles and helping to compensate for springback.

Daylight Opening

Daylight refers to the space between the upper and lower beams when the press brake is fully open. This gap determines the maximum size of the material and tooling that can be positioned in the metalworking machine. Larger daylight openings enable the bending of taller workpieces and allow for the use of specialized tooling.

Speed and Control

The speed of the upper beam directly affects production efficiency. Modern machines allow press brake operators to adjust the speed at various stages of the bending cycle, from rapid approach to precise bending, ensuring both speed and accuracy. CNC systems provide enhanced control, enabling precise programming of settings for force, speed, and angle, improving consistency and reducing errors.

Advantages of U Bending

U bending offers several notable benefits:

- Versatility: Suitable for a wide range of materials and thicknesses, making it applicable across industries.

- Precision: Advanced press brakes with CNC controls ensure consistent and accurate results.

- Cost Efficiency: The process minimizes material waste and is adaptable to both small-scale and high-volume production. For example, in the automotive industry, U bending has been shown to reduce manufacturing costs for frame components by optimizing material usage.

Practical Guide

Step-by-Step Guide to Performing a U Bend

Choose proper press brake and dies: choose mechanical or hydraulic press brake based on material type and thickness. Choose the appropriate upper and bottom die according to the required u-bend size and shape.

Material preparation: measure and cut the metal sheet into the required size.

Set the machine parameters: set the reasonable bending force, speed, and angle parameters according to material thickness and bending radius.

Operate the bending: put the metal sheet on the press brake, ensure it is in the middle of the die, and bend it according to the decided parameters.

Check and adjust: monitor the material deformation, check the accuracy of the size and angle, and timely adjust the pressure and angle to compensate for the spring-back effect. After one or two sides' initial bending, accomplish the other part of bending according to the same procedures.

Technique: use accurate measuring tools to verify die position and angle setting many times.

As for complex U-shaped workpieces, the step-by-step forming method can be accepted. Bend a small section at a time, and keep the section constant and consistent.

Develop standardized operating procedures, proceed strictly, and improve operational proficiency through repeat practice.

How to calculate the bend radius in a press brake U-bend?

- Understand the Basics of Bend Radius

- The bend radius in a press brake U - bend is the radius of the inside curve of the U - shape. It is a crucial parameter as it affects the structural integrity, appearance, and functionality of the bent part. A smaller bend radius can result in a more compact U - bend, while a larger radius may be needed for parts that require more flexibility or to avoid material cracking.

- Material Thickness Factor

- The material thickness (Rmin) is a key factor in calculating the minimum bend radius. As a general rule, the minimum bend radius () is related to the material's thickness. For most metals, there is a recommended minimum bend radius to prevent cracking. For example, in mild steel, the minimum bend radius is often around 1 - 2 times the material thickness. That is Rmin =(1-2)t.

- The exact ratio depends on the material's ductility. Ductile materials like aluminum can generally have a smaller bend radius relative to their thickness compared to less ductile materials like some high - strength steels.

- Tooling Considerations

- The tooling used in the press brake also affects the bend radius. The punch and die radius play a significant role. The punch radius (r,) should be slightly smaller than the desired final bend radius (R). The relationship between the punch radius and the bend radius can be approximated as , where is a small adjustment factor that accounts for spring - back. Spring - back is the tendency of the material to partially return to its original shape after bending.

- The die radius () is usually larger than the punch radius and is designed to accommodate the bent material and provide support during the bending process. A common rule of thumb is that the die radius is about 1.5 - 2 times the punch radius ().

- Calculation Formula Based on Geometry and Material Properties

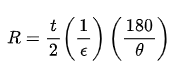

- For a more accurate calculation, you can use the following formula based on the neutral axis concept. The neutral axis is the layer within the material that neither compresses nor stretches during bending. The formula for the bend radius () considering the material's thickness (), the bend angle (), and the elongation factor () is:

- where is the elongation of the outer fiber of the material during bending and can be obtained from material property tables or through testing. The bend angle is measured in degrees.

- In practice, it's also important to consider any allowances for spring - back. Spring - back can be estimated through trial - and - error or by using empirical data provided by the material supplier or the press brake manufacturer. Typically, you may need to adjust the calculated bend radius by a certain percentage (usually around 5 - 10%) to account for spring - back, depending on the material and the bending process.

Common Mistakes and How to Avoid Them

Improper choice of dies and inaccurate die gap setting will lead to a bad bending effect or workpiece damage. If the bending force is too large or small, this will result in the material breaking. Springback is overly large, which will affect the product precision. Improper position of the material and fixation will lead to offset during the bending process.

There are some approaches for precautions based on the above questions:

Strictly obey the operational manual, choose the die integrated with practice experience, check regularly, and adjust the die gap.

Calculate the bending force according to the material properties and thickness, and also take the spring back into consideration, appropriately increasing the compensating volume.

Enhance the operator training and improve the material clamping and positioning accuracy.

Maintenance and Care of Press Brake Machines

Daily maintenance

Regularly clean the inner and outer debris of the press brake, ensure the lubricating system is smooth, and supplement or replace the lubrication oil in time.

Check the hydraulic system seal properties to avoid oil leaking, ensuring hydraulic components work correctly. Maintain and check the electricity control system, ensuring the components work stably and safely. Check the die's abrasiveness situation, grinding, repairing, or replacing the new dies when necessary.

Long-term maintenance strategies

Develop detailed equipment maintenance plan, check and repair regularly, to prevent potential malfunctions from happening.

Establish the using record, and track the equipment operation condition, to offer evidence for later maintenance.

Raise employees' awareness of the importance of equipment maintenance, and develop a good operation habit, to prolong the press brake lifespan and working efficiency.

Industry Applications

U Bends in Various Industries

Automobile industry

In automobile manufacturing, u bend is widely used in producing exhaust system ducts, suspension components, and body structural parts. It is strict for the material chosen, bending process precision, and products’ durability because these components usually need to bear high temperature, high pressure, and vibration.

Aerospace industry

The aerospace industry has extremely high requirements for lightweight and high strength. U bend process is usually used in aircraft fuel delivery systems, fuselage frame structures, and other internal pipeline layouts, ensuring each part can meet strong standards and achieve weight loss goals.

Architecture industry

In the construction industry, u-shaped steel or tubes are widely used in structure support, exhaust systems, HVAC piping, etc. Especially in steel structure architecture, pre-bent u-shaped beams can improve working efficiency and structure stability, which is convenient for spot assembly.

Future Trends in Press Brake U Bending

Emerging technologies and methods

CNC technology and automation degrees are constantly improved, making the press brake able to accomplish more complex U-shaped bending tasks, and decrease the error brought by the manual intervention.

The machine technology and intelligent production system are brought to make u bend more efficient, flexible, and adapted to small-scale, sorts of varieties and custom production needs.

Material science development, like the emergence of new composite materials, will challenge the press brake process, and also provide u bend technology with the possibility of innovative applications.

Metal fabrication industry anticipation

Future press brake technology will stride to high precision, faster speed, and large flexibility to handle the more complex workpiece design.

The concept of green environmental protection is deeply rooted in the people's hearts. The equipment and technology with low consumption, and high production will be the mainstream, including the application of the energy-saving hydraulic system, recycling of waste heat, and other measures on the press brake.

Digital and network technology will further be integrated into the metal forming process. The production process will be improved by the Internet of Things, and Big Data Analysis, thus improving the overall production efficiency and quality.