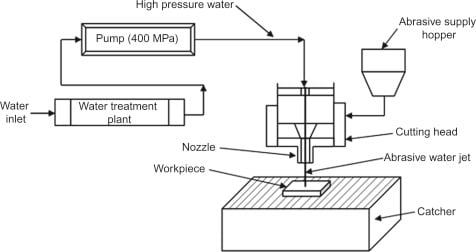

Waterjet cutting is a high-speed erosion process where highly pressurized water is forced through a ruby or diamond nozzle into a mixing chamber. This pressure creates a vacuum, drawing garnet sand into the water stream. The resulting mixture is then blasted at the material, causing rapid erosion that effectively cuts through it. This process has made waterjet cutting a powerful and versatile technique widely used across various industries globally.

What Is Waterjet Cutting?

Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut a wide range of materials.

A high-pressure water pump pressurises the water. This water flows through high-pressure tubing into the cutting head. In the cutting head, the water flows through a nozzle, turning it into an extremely fine stream. This stream cuts whatever material is placed in front of it.

A waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part.

It is easy to manipulate the nozzle to accommodate the cutting of different materials. Depending on whether an abrasive substance is used or not, there are two types of waterjet cutting methods:

- Abrasive waterjet cutting

- Pure waterjet cutting

Abrasive waterjet cutting

1. high-pressure water inlet; 2. jewel (ruby or diamond); 3. abrasive inlet; 4. mixing tube; 5. guard; 6. cutting water jet; 7. cut material

When cutting harder materials, abrasive agents are mixed with the water. This occurs in a mixing chamber located in the cutting head just before the abrasive jet exits the system.

Popular agents for abrasive waterjet cutting are suspended grit, garnet and aluminium oxide. As the material thickness/hardness increases, so should the hardness of the abrasives in use.

With the right abrasives, various material types can be cut. Common materials cut with abrasives are ceramics, metals, stones and thick plastics. There are, however, certain exceptions such as tempered glass and diamonds that cannot be cut with abrasive water. Tempered glass shatters when cut with a water jet.

Pure waterjet cutting

Water jet cutters also work without the addition of abrasives, mainly to cut soft materials. A waterjet cutter designed only for this purpose does not have a mixing chamber or a nozzle. A high-pressure pump forces pressurised water out of an orifice to create precise cuts on the workpiece. Although most industrial cutting devices using waterjet technology enable the use of both methods.

Pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. The jet stream is also exceptionally fine and does not impart any additional pressure on the workpiece.

Pure waterjet cutting is ideal for softer materials like foam, felt, wood, rubber, food and thin plastics.

The Key Components of a Waterjet Cutting System

For waterjet cutting systems to function effectively, several essential components work together, each with a specific purpose to ensure precision and efficiency:

- Pump - generates ultra-high-pressure water, typically up to 6,000 bar, for advanced systems like Flow's HyperJet®.

- Cutting head - houses the orifice, typically made of ruby, sapphire, or diamond. The orifice focuses the high-pressure water into a fine, high-velocity stream, serving as the primary cutting tool for precise and intricate cuts.

- Mixing chamber - in abrasive systems, garnet sand is introduced into the water stream, combining to enhance cutting capability.

- X/Y table - responsible for the precise movement of the cutting head during the cutting process. It allows for the creation of complex shapes and patterns by controlling the direction and speed of the cutting head, ensuring high precision.

- Control software - programs like FlowMaster® control the cutting process, ensuring accuracy and efficiency.

Working Principle of Waterjet Cutting

The working principle of water jet is based on two core elements: high-pressure water flow and abrasive.

First, water is pressurized to extremely high pressure by a high-pressure pump, usually up to hundreds of MPa. Such high-pressure water flow is ejected through a special nozzle to form an extremely fine and extremely fast water jet. When this water jet hits the target material, it will generate a huge impact force, thereby achieving the cutting of the material.

However, cutting only by high-pressure water flow will be limited in cutting ability and efficiency. In order to enhance the cutting ability of water jet, people introduced the element of abrasive. Abrasives are usually fine particles with high hardness, such as garnet, aluminum oxide, etc. These abrasives are mixed into the high-pressure water flow and impact the target material together with the water jet. Under the action of the impact force, the abrasive will scrape and grind the surface of the material, thereby greatly improving the cutting efficiency and cutting ability of the water jet.

Benefits of Using Waterjet Cutting

Superior Edge Quality

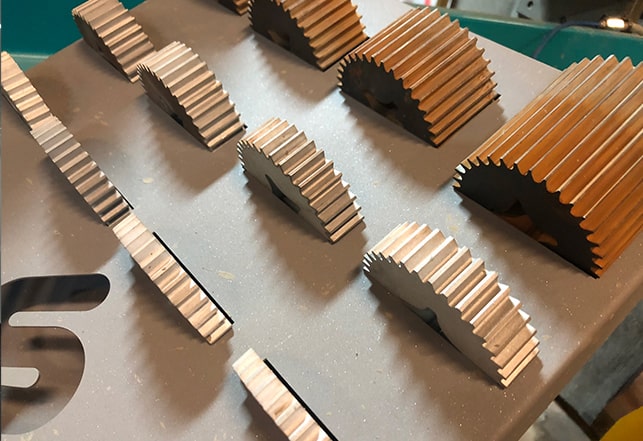

No other cutting method comes close to the superior edge quality you will experience using waterjet cutting. Smooth, uniform burr-free edges are the reasons as to why designers and manufacturers specifically choose this method of cutting.

The superior edge quality is achieved by using a combination of water speed, pressure, nozzle size and abrasive flow rate. In many cases waterjet cutting eliminates the need for secondary finishing, which saves a substantial amount of time, cost and improves the efficiency within your production line.

Gain Efficiency & Save On Cost in Your Workshop

Waterjet cutting is becoming one of the most cost-effective solutions on the market because it is a cold cutting process. Alternative hot cutting techniques face the likelihood of their parts/fittings experiencing heat zones which often cause the parts to warp making them inaccurate and unusable. Waterjet overcomes this quite easily with its cold cutting process so that chances of you throwing away material will virtually become non-existent.

Time and efficiency in your workshop will improve due to the fact that waterjet cutting requires little edge treatment or secondary finishing after the cut is made. This means you are able to make a start onto your next cut or project whilst others who use alternative cutting

Super Accurate Internal Cut-outs

With the cutting accuracy of ±0.1 to ±0.2mm, Waterjets become the tool of choice when making internal cut outs. Artwork, custom patterns, unique designs and logos can all be manufactured easily using the waterjet cutting process. This gives your business the ability to provide a greater service to your customers.

Material & Thickness Don’t Matter When Using A Waterjet Cutting Machine

The needle-sharp cutting stream made up of a mixture of water and abrasive solution cuts through most materials available in manufacturing. Restraints on material thickness will become a thing of the past as you are able to cut products such as aluminium, multi-layer materials, composites and hardened steels over 25mm thick.

No Heat Affected Zones

Heat distortion and hardened edges were a common problem faced by manufacturers before waterjet cutting was introduced. Cutting processes that generated high heat were used which created significant problems for workshops. One of the major problems faced was heat zones being created within materials which causes the molecular structure of that material to change. This has secondary effects on the material which often led to warping, inaccurate cuts or weak points being created within the material. Workshops can now eliminate all of these problems by simply choosing waterjet cutting which uses a cold cutting process.

No Tool Changes Required

Operating efficiency is improved because waterjet cutting allows you to cut different materials without changing any tools. No need to change nozzle heads when a new material is placed on the table, just simply adjust your feed rate to the appropriate speed to match the material type and thickness and you are on your way to making your next cut. In many cases workshops improve their profitability as less time is wasted changing tools whenever a new cut is being made.

Waterjet Cutting Materials

The process is compatible with a wide range of materials. In this section, we shall take a look at the different types of materials that can be cut effectively using a water jet cutter. We’ll cover:

- Metals

- Wood

- Rubber

- Ceramics

- Glass

- Stone and tiles

- Food

Metals

The high velocity and pressures in waterjet systems make them capable of cutting thin and thick metals with relative ease. This process is capable of cutting extremely hard materials such as titanium and inconel along with common metals such as aluminium and mild steel.

The process is mainly used to cut thicker workpieces that can’t be cut with laser or plasma. For thinner metals, laser cutting has an edge over waterjet in terms of cutting speed. A waterjet cutter with a 30 HP pump can cut 12 mm titanium at a rate of 180 mm/min.

For metals, waterjet provides the advantage of no HAZ formation which improves the final quality of a part significantly. There is also no need for secondary finishing in most cases as this process provides satin-smooth edges.

Waterjet cut metal parts have high quality and are thus used in the most demanding sectors such as the aerospace industry that have no margin of error.

Wood

A decent waterjet cutting machine can effectively cut wood up to 125 mm in thickness at a rate of up to 15 m/min. It can be used to split wood as well as to carve intricate shapes. Moreover, the stream passes the wood at such a high speed that it causes virtually no surface wetness. This prevents the wood from absorbing the water. The high pressure also causes minimal delamination.

However, the machine may have to be recalibrated if there are knots in the wood. Either we can use a higher pressure that can cut through the knots along with non-knotted areas or use different pressures for different areas. Using either option can affect the final quality of the part.

Rubber

Waterjet technology is also increasingly used to cut rubber with varying thicknesses. A key advantage of a waterjet cutter is that it does not create concave edges, unlike die-cutting.

The technology is also not limited by the thickness of the rubber. The abrasive waterjet machine can cut rubber of varying hardness and thickness to the desired final quality.

In many cases, pure water jet cutting may be enough to meet product specifications for rubber products. Pure water jet cutting can easily cut sponge rubber of up to 50 mm thickness and hard rubber greater than 25 mm thickness up to a bidirectional tolerance of 0.25 mm.

Ceramics

Waterjet technology is commonly used in industrial cutting devices for ceramics. Ceramics are hard and brittle and difficult to machine. They cannot withstand the excessive pressure that a workpiece is subjected to in other mechanical cutting methods.

In waterjet cutting, no excessive pressure is applied to the workpiece except at the cutting point. This makes it ideal for cutting ceramics. The cutter can pierce its own starting hole and precisely cut complex shapes.

CNC (computer numerical control) technology is used in conjunction with abrasive waterjet cutting to ensure repeatable accuracy and good edge quality.

Glass

Waterjet cutting can cut a variety of glass with incredible detail. It can cut the most delicate glass without cracks or craters on it. On the other end of the spectrum, you may use it to cut stained glass.

Cutting with a waterjet does not require etching or breaking. But starting holes are pierced at a lower pressure due to the tendency to crack. A waterjet can cut up to 50 mm of bulletproof glass, this number is even greater for other types of glasses.

Stone and tiles

Stone and tiles are another common application for waterjet cutters. With the right technical settings, we can use a waterjet cutter for cement, ceramic, glass, granite, limestone, mosaic, metal, porcelain, travertine and quarry tiles.

Working Steps of Waterjet Cutting

1) Booster system

At the beginning of operation, ordinary water is boosted by a high-power high-pressure pump driven by an electric motor, raising the water pressure to hundreds or even thousands of megapascals (MPa). This process is achieved through a hydraulic transmission system, which includes a plunger high-pressure pump that can convert oil pressure into water pressure.

2) Energy conversion

The electric motor outputs electrical energy and drives the oil pump through a belt drive system, thereby generating high-pressure oil pressure. The high-pressure oil pushes the piston in the booster to reciprocate, converting the oil pressure energy into water pressure energy.

3) Waterjet generation

After the pressurized water passes through the accumulator to stabilize the pressure, it is ejected through a nozzle made of gemstone or carbide with a very small diameter (usually between 0.1 and 0.4 mm), forming an extremely fast and highly focused water jet, whose speed can reach more than 3 times the speed of sound.

4) Mixed abrasives

For cutting harder materials, fine abrasive particles (such as garnet sand, corundum, etc.) can be added to the high-pressure water jet. These abrasives are accelerated to a very high speed to form a water jet containing abrasives, which greatly enhances the cutting ability and can cut hard materials such as rocks, metals, and glass.

5) CNC control system

The entire waterjet cutting process can be accurately controlled by a computer numerical control (CNC) system, which can cut complex shapes and plane contours and realize automated processing.

6) Underwater cutting

In some cases, the water jet can also be cut underwater in a water tank. This working mode can reduce the atomization phenomenon caused by the water jet cutting in the air, reduce noise, and keep the working environment clean.

Application of Waterjet Cutting

As waterjet cutters support a wide range of materials, they are used by a lot of different industries. The main factor that leads to the popularity of this method is that water jet offers countless benefits over other alternatives such as laser cutting. Here is a brief description of the various applications of this method:

Food Cutting & Food Processing Equipment

- Waterjet cutting is the preferable method in the food processing industry. This is because this cutting method involves high sanitation, and preserves the integrity of the food without contaminating it.

- This method is heavily used for meat processing, vegetable slicing, and manufacturing snacks and cake products.

- Since waterjet cutting eliminates the need for manual tools such as knives, it significantly increases the safety of the workers in the food processing facility.

Aerospace industry

- The aerospace industry involves working with toughened substances that require precise cuts. Waterjet cutting is used in the aerospace industry for all these requirements, especially when making turbine blades, parts of a jet engine, or cutting composite materials for aircraft.

Automotive industry

- Waterjet cutters are installed in the production line of the automotive industry. These cutters make the required incisions for fine engine components of automotive and other gear parts.

Defence and Military

- The complex components used in defense and military sectors are created by waterjet cutters. Usually, 5-axis or 6-axis cutters are employed for the purpose. Extra hard materials like kevlar composites are also cut through this method.

Rubber & Composites Cutting

- Waterjet cutting is used to cut rubber and composite materials for boat shells, panel insulations, home insulations, personal watercraft bodies, etc.

- The benefit that this method offers is that cutting can be achieved without melting the workpiece, and without releasing any toxic fumes.

Medical & Surgical Equipment

- The wide versatility and high cutting precision of waterjet cutting make it the perfect fit for cutting materials for medical and surgical equipment. These materials constantly evolve with engineering advancements, so the cuts can be made and modified as per requirements.

- Due to the possibility of angular cuts, it is used to make complex equipment for liposuction applicators, liver resection, bone divisions, etc.

Architectural & Art Work

- Waterjet cutting is commonly used for cutting fiberglass, metals, cement boards, and other materials used in architectural and construction work.

- Complex architectural artwork in false ceilings and other installations is also created by waterjet cutters.

- Since waterjet cutting does not cause any jagged edges, it is also used for the cutting of wallpapers.

Electronics

- Electronic and microelectronic components are highly sensitive to heat. Their electrical properties can change if heat-affected zones are created. This is why a highly precise cold cutting process like abrasive waterjet cutting technology is perfect for the electronics industry.

Job Shops

- Job shops often handle a lot of different materials and a lot of different cutting requirements. Therefore, abrasive waterjet cutters are used in job shops because they offer the most versatility among any professional cutting process.

Metal Service Centres

- Metal service centers require a cutting method that can work on a large area of material with a high cutting speed. This is why waterjet cutting is used in the industry extensively.

- Another benefit of waterjet cutting is that it can perfectly work on metals that are poor conductors of electricity. For arc-based cutting technologies, that is not the case.

Education & Research

- Waterjet cutting is also used for making prototypes and models of products in the research phase. With angular cuts and high precision, the prototypes created with waterjet cutting can be made to look as intended by the imagination.

Experimental & Laboratory Environments

- Abrasive waterjet cutting works quite well for common lab equipment such as stainless steel and alloys. It can handle all the materials used to make experimental equipment.

- The structural integrity of the component is preserved and the tolerances are known beforehand. Therefore, this cutting method can also be used to make graded equipment such as calipers and rulers.

Oil & Gas

- Abrasive waterjet cutting is utilized to cut materials like Inconel, Hastelloy, and stainless steel for oil and gas subsea equipment.

- One of the major benefits is that since there are no heat-affect zones, the abrasive waterjet cut equipment is more reliable than other heat cutting alternatives.

Mining

- Abrasive waterjet cutting is extensively used for mining coal and other natural substances. In fact, specialized waterjet cutters for mining can cut stone up to a thickness of 100 feet!

Water Jet Cutting Vs Traditional Methods:How do I choose the right method for me?

We often tell these people that each method is different, but in order to make it easier to choose we thought that we would directly compare waterjet cutting with traditional methods. In this section we will answer some of the most commonly asked questions so that you can make an informed decision about what method would best suit you.

| Comparison Items | Waterjet | Laser | Plasma | Mechanical |

|---|---|---|---|---|

| Common Applications | Stone, plastics, ceramics, thick metals, reflective metals, foods, composites, rubber & glass | Metals excluding reflective | All metals | Stone, plastics, ceramics, thick metals, reflective metals, foods, composites, rubber & glass |

| Stress on Material | No stress or molecular change (cold cutting) | Deformation, tempering and structural changes | Deformation, tempering and structural changes | Deformation, tempering and structural changes |

| Energy Consumption | 20,000 Watts | 40,000 Watts | 55,000 Watts | N/A |

| Max Cutting Thickness | Up to 304 mm for most materials | Up to 25mm mild steels, 12mm stainless steels and 10mm aluminium | Up to 150mm | From 3mm to 10mm |

| Cutting Waste | Water and grit | Dust and fumes (require vacuum extraction and filtering) | Dust and fumes (require vacuum extraction and filtering) | Mostly dust |

| Chances of Secondary Finishing | Highly Unlikely | Very Likely | Extremely Likely | Very Likely |

Conclusion

As can be observed from the preceding responses, KRRASS Waterjet cutting emerges as the most adaptable and secure cutting technique available in the market. Its capacity to handle thicker and a more extensive array of materials while maintaining a safe operational environment has established it as the premier cutting approach across diverse industries. If you are eager to acquire further details about our machines, you have the opportunity to watch our live demonstration of the KRRASS Waterjet cutting machine.