We present the results of experiments exploring the feasibility of using a fiber-coupled Nd:YAG laser for cutting thick mild steel plates (thickness > 15 mm). The tests were conducted with a continuous wave 2.5 kW Nd:YAG laser, which was delivered to the workpiece through a 0.6 mm diameter silica core optical fiber. The mild steel samples used in the study ranged from 10 to 50 mm in thickness. The effects of various operating parameters—including focal spot size, cutting nozzle position relative to the steel surface, assist gas pressure, laser power, and cutting speed—on the quality of the cut surfaces were investigated and analyzed.

Preliminary results indicate that it is possible to cut mild steel plates up to 50 mm thick at speeds of up to 200 mm/min with as little as 500 W of Nd:YAG laser power. The resulting cut surfaces were smooth and free of dross, suggesting that Nd:YAG laser technology holds significant potential for cutting thick steel plates.

Introduction

Laser Cutting in the Materials Processing Industry

Laser cutting accounts for approximately one-quarter of the laser materials processing industry [1]. Over the past 30 years since the first gas-assisted laser cut was achieved [2], the fundamental method of laser cutting has seen little change. For cutting mild steels, the laser beam is typically focused at or near the workpiece surface and is surrounded by a co-axial stream of oxygen assist gas. Typically, laser powers up to 3 kW are employed to cut mild steels with thicknesses ranging from 12 to 15 mm, while thicker plates are generally cut using plasma or oxy-fuel systems. Although CO2 lasers are capable of cutting metals up to 40 mm thick, there is a significant reduction in cut quality and reproducibility with increasing thickness [3].

Challenges in Cutting Thicker Materials

One approach to cutting thicker mild steel plates is to increase the laser power. While this method offers several advantages, it also presents significant challenges. At higher powers (3.5 kW and above), the beam quality can become unstable, reducing the lifespan of optical components, increasing equipment and operating costs, and impairing cutting precision. As demonstrated in [4], although the kerf thickness remains approximately constant for a given surface finish quality, the cutting speed does not decrease in direct proportion to the material thickness, which suggests a decline in cutting efficiency as material thickness increases.

This reduction in cutting efficiency with increasing material thickness is attributed to the decreasing ability of the assist gas to shear the molten material. As the thickness increases, the pressure of the assist gas must also increase to effectively remove the molten material. However, with oxygen as the assist gas, the exothermic reaction occurring in the kerf requires a reduction in oxygen pressure as the material thickness grows to prevent excessive burning and overreaction. Therefore, managing the oxygen pressure becomes crucial to avoid uncontrolled burning outside the heated area. This creates a contradiction in requirements: while increasing the laser power can extend cutting performance, it is not sufficient to overcome the limitations imposed by the need to control oxygen pressure. This presents a barrier to achieving greater cut thicknesses, despite the potential of higher laser power.

Alternative Methods for Cutting Thick Steel

To overcome the limitations of increasing laser power, numerous techniques have been developed to maintain or enhance cutting performance as mild steel thickness increases. Some of these methods include: laser flame cutting [5], dual-focus lenses [6], beam sawing with adaptive optics [7], laser cutting using a co-axial (annular) nozzle [8], dual-beam CO2 laser cutting [9], spinning laser beams [13, 14], and Laser Assisted Oxygen Cutting (Lasox©) [10 – 12].

Wobbling and Oxygen-Dominated Nd:YAG Laser Cutting

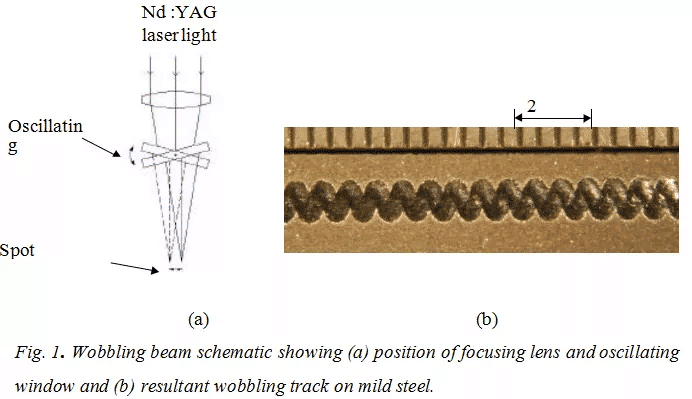

In previous work, we have reported on cutting thicker mild steel plates using a spinning Nd:YAG laser beam [14]. In this study, we investigate the use of a fiber-delivered Nd:YAG laser with a wobbling beam (a technique similar to spinning the beam) and the oxygen-dominated laser cutting method, similar to Lasox cutting [10, 11, 12]. Oxygen-dominated Nd:YAG laser cutting trials were conducted first with low oxygen assist gas pressures and then with high oxygen pressures.

This novel approach aims to address the challenges of cutting thick mild steel by improving material removal efficiency while managing the issues related to assist gas pressure and beam stability.

2.2 Cutting steels using laser assisted oxygen dominated approach

The method of laser assisted oxygen dominated cutting was implemented on AS3678 mild steel plates of thickness 16 to 50 mm. Oxygen assist gas pressures were kept to either less than 120 kPa (low pressure oxygen cutting –LoPOx) or to high pressures (high pressure oxygen cutting – HiPOx). Cut results were recorded as a function of cut quality (cut striation, kerf shape, excessive dross) and cut speed.

Results

3.1Wobbling the laser beam.

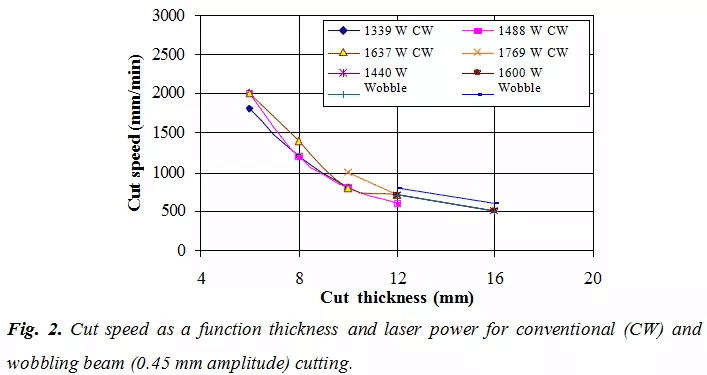

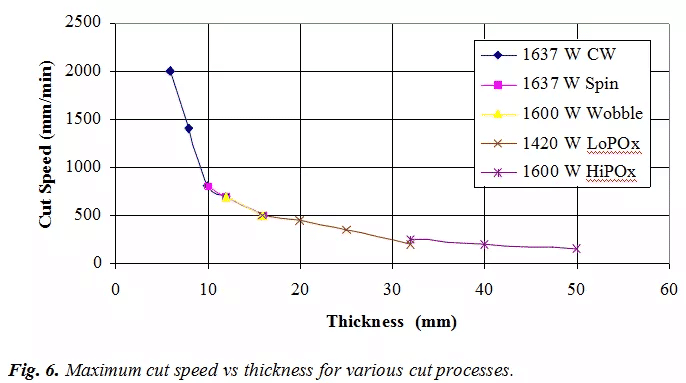

By wobbling the beam on the workpiece the maximum cut thickness was increased from 12 mm, encountered with conventional cutting, to 16 mm. A graph of maximum cut speed for various thicknesses and laser powers, seen in Figure 2, indicates that though the cut thickness was improved with the wobbling beam, the cut speed is similar to that of conventional (CW) cutting, This indicates that the cut process occurring within the kerf remain unchanged during wobble beam cutting. Similar cut speeds were also achieved with the spinning beam [14].

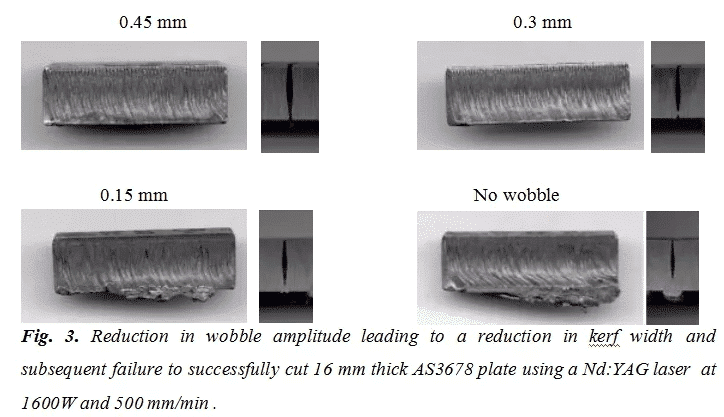

The increased cut thickness can be attributed to the increased kerf width. This is demonstrated by varying the amplitude of the wobble as shown in Figure 3. Here, as the wobble amplitude is sequentially reduced from a maximum amplitude of 0.45 mm to zero, the kerf width is reduced, corresponding to a reduction in the ability to clear the melt. This clearly demonstrates the necessity to have adequate kerf width to allow dross to clear. This view is also expressed by others [12], where it is suggested that both fluid dynamics and thermodynamics are constrained by narrow kerfs.

3.2 Cutting steels using laser assisted oxygen dominated approach

3.2.1 Low Pressure Oxygen Dominated Cutting – LoPOx

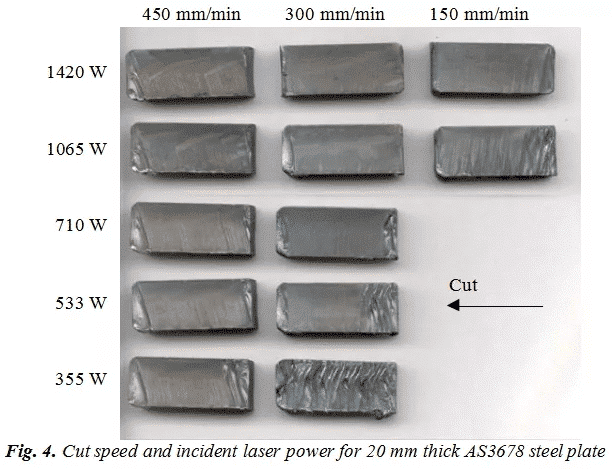

The LoPOx cutting process uses the same larger diameter laser beam and narrow imposing oxygen jet at the top of the workpiece as seen in the Lasox process, however with assist gas pressures below 120 kPa. Cut surfaces shown in Figure 4 using the LoPOx process demonstrate that low incident laser powers do not hinder laser cutting as long as primary and ongoing initiation of the cut is able to take place. Indeed as cut speed increases, incident laser power may contribute too much energy and therefore cause excessive striation to take place. This is demonstrated in the figure by observing the 450 mm/min cut speed, where a better surface was generated by 533 W incident laser power than was achieved at 1420

W. Here, the rate of exothermic reaction is determined by the cut speed. Incident laser power is only required to heat the top surface to greater than 1000C [11] and initiate the reactive fusion process. Excessive incident laser power reduces the cut quality. This demonstrates that issues of oxygen – iron interaction, not the incident laser power, now primarily govern the cut quality. Hence this is an oxygen dominated laser cutting process.

In Figure 4 as the power is reduced for each cut speed first indications of minimal incident power is the poor start of cut as seen at the right hand end. This demonstrates that power requirements at cut initiation are higher than those of the ongoing cutting process and the power required for quick establishment of a steady cut process and not power for the ongoing process is the essential criteria.

When LoPOx cutting using a smaller co-axial nozzle diameter for the same thickness material, the same cut speeds are obtained but with a narrower kerf width and consequently reduced oxygen flow. However the high quality cuts were unable to be achieved at the lower laser powers with the larger nozzle diameter used in Figure 4. This is in spite of a more intense laser spot as a result of passing through a smaller diameter nozzle. This demonstrates that the requirement of a sufficiently wide kerf to allow the dross to clear applies equally for the oxygen dominated cutting process.

The sides of the cut are tapered more than those encountered in conventional (laser dominated) cutting. The oxygen dominated nature of the cut process means that the kerf is influenced by the shape of the imposing oxygen jet with the top of the kerf being the same width as the co-axial nozzle used.

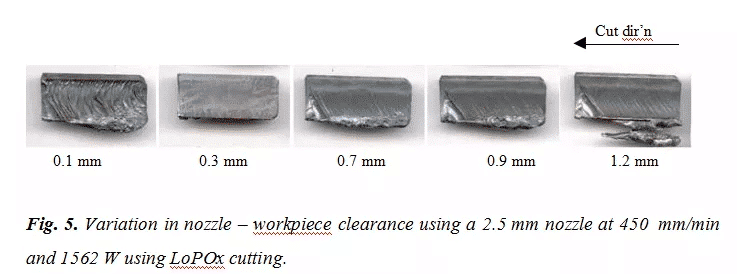

The clearance between the nozzle and workpiece was varied with typical results of this variation shown in Figure 5. For various nozzle diameters, cut quality was reduced significantly with clearances greater than 25% of the nozzle diameter. Increases in nozzle– workpiece clearance exposed more of the flow from the nozzle to the ambient atmospheric gasses before entering the kerf [8]. The change in clearance was undertaken without corresponding changes in laser spot diameter with similar results. This further demonstrates that changes to assist gas and not incident laser power intensity was the factor affecting laser cut quality over the range tested. Figure 5 also shows the effect of a too small a clearance (0.1 mm) where the converging beam is not yet exceeding the gas jet diameter therefore not permitting the oxygen dominated laser cutting process to operate.

A maximum cutting thickness of 32mm was achieved using Nd:YAG LoPOx cutting. Cutting beyond this thicknesses with the nozzle diameters used caused the formation of excessive dross within the kerf and a loss of perpendicularity of the cut. This further demonstrates the relationship between kerf width and cut thickness when low (conventional) cutting pressures are used.

3.2.2High Pressure Oxygen Dominated Nd:YAG Laser Cutting – HiPOx

Using a much higher supply pressures and smaller diameter nozzles, it was found to be possible to cut steels thicker than those previously obtained by the LoPOx process. Cut capacity was shown to be between 32 and 50 mm thickness using AS 3679 steel plate. Typical cut speeds with respect to material thickness and laser power are shown in Figure

6. The figure shows a continuation of cut processes from the low pressure region used for thinner materials.

The effect of using high delivery pressures mean that the flow of the gas is complex and can give rise to internal shock features. Evidence of the interaction of shock structures during cutting can be seen as “ridges” or lesser marks in the cut surface and seen as lines running perpendicular to the stria. Further, the shifting of these ridges with nozzle- workpiece clearance results from reinforcement or annulment of assist gas internal shocks and the characteristic shock appearing at the start of the kerf in the shape of an “X” [15]. Work [16, 17] also indicates a complex and sometimes oscillatory interaction of shocks with the kerf walls. Evidence of the oscillatory nature of the cut is in the steady “buzz” that can be heard under some cutting conditions.

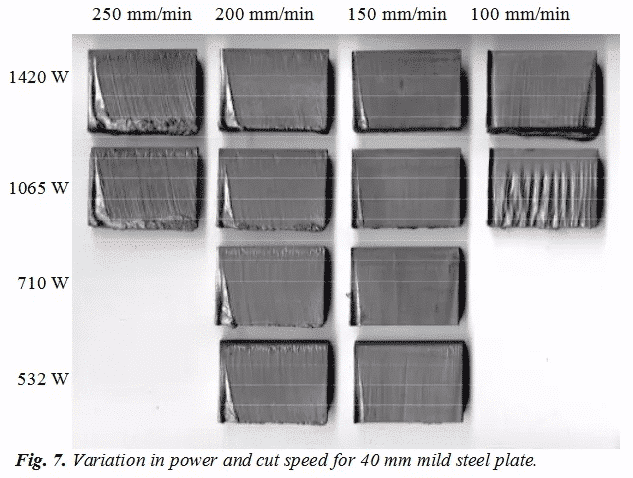

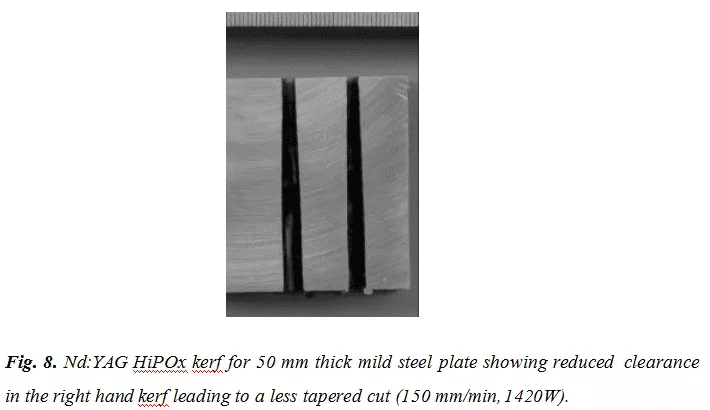

Using a 1.5 mm diameter co-axial nozzle, cut capacity was shown to be satisfactory for 32 and 40 mm plate with results of cutting 40 mm plate shown in Figure 7. Nozzle- workpiece clearance was significantly increased with the high assist gas pressures and the shape of the kerf was far less tapered than that seen in LoPOx as a result of the less divergent high velocity gas stream. Such kerfs can be seen in Figure 8.

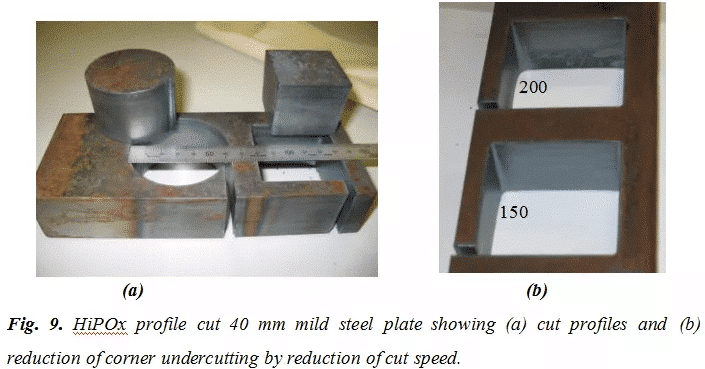

Profile cutting using the fibre delivered Nd:YAG LoPOx technique is feasible with examples shown in Figure 9. Here temperature increases on the inside of corners result in increased tapering at these points. This is seen on the circular cut of Figure 9 (a) and undercutting of corners in Figure 9(b). Undercutting of sharp corners is best overcome by the use of reduced cutting speeds as shown in the figure.

High pressure oxygen dominated cutting using the Nd:YAG laser like that used with the CO2 [12] also shows itself to be excellent in piercing with less than one second required to pierce 32 mm AS3679 plate. The removal of dross ejected upwards remains an issue, with its presence on the plate surface in the cut path detrimental to cut quality

Discussion

Challenges of Cutting Thick Steel Plate

Despite the novel advancements in laser cutting techniques and the ability to cut thicker materials, the fundamental cutting process remains largely unchanged. This is evident from the reduction in cutting speed as material thickness increases, as well as the consistent cutting speeds observed across conventional, spinning beam, and wobbling beam methods. In all cases, the primary factors governing the cutting of thick steel plates by reactive fusion—such as heat losses to conduction and limitations in melt flow removal due to viscosity and surface tension—continue to pose significant challenges. These factors are not easily overcome, even with the development of new cutting methods.

The Role of Kerf Width and Oxygen Consumption

The varying kerf widths produced by wobbling the laser beam, as well as those generated in oxygen-dominated laser cutting with the Nd:YAG laser, highlight the need for appropriately wide kerfs as material thickness increases. However, at moderate material thicknesses (~32 mm), increasing the kerf beyond that produced by the largest LoPOx nozzle becomes impractical due to the prohibitive oxygen consumption.

In this context, the use of HiPOx (high-pressure oxygen) provides a promising solution. The high-pressure, high-velocity assist gas stream helps reduce the mixing of oxygen with atmospheric gases, making more oxygen available for the reactive fusion process. Additionally, the increased pressure generates significantly higher shear forces on the molten material, assisting in the removal of the melt from the kerf. Another advantage of the HiPOx technique is the large nozzle-to-workpiece clearance it allows, which ensures the reliable operation of high-pressure nozzles, especially when cutting thick materials.

Laser Power Requirements for Oxygen-Dominated Cutting

Oxygen-dominated cutting relies primarily on the incident laser power to initiate and sustain the cut. The results from this study indicate that the laser power required for oxygen-dominated cutting is substantially lower than that required for conventional laser cutting. However, while the power required to maintain a steady cut is lower, higher powers are needed initially to establish the cut. Once the cut is initiated, the laser power can be reduced to a level that sustains the cutting process. This suggests that a power boost at the start of the cut could maximize overall cutting efficiency, by using higher power only when necessary for initiation.

Profile Cutting and Corner Undercutting

Profile cutting using the oxygen-dominated Nd:YAG laser process has been demonstrated to be feasible. However, a common issue is undercutting at the inside corners of the cut profile. This problem can be managed by carefully programming the cut speed at these specific positions to avoid excessive material removal and ensure clean cuts.

Piercing and Dross Management

Piercing thick steel plates with a Nd:YAG laser is also feasible, but challenges arise from the upward ejection of molten dross during the piercing process. This dross can interfere with the delivery of assist gas during subsequent cutting, leading to poor cut quality. A solution to this problem could be the introduction of an outward-facing annular air jet surrounding the nozzle, which would help direct the dross away from the kerf. Alternatively, the issue could be addressed by programming a CNC wait command after all piercing operations are completed, allowing time for the removal of any ejected dross before the cutting continues. This would help maintain a consistent flow of assist gas and improve the overall cutting performance.

Conclusion

Oxygen-dominated laser cutting, coupled with wider kerf widths, proves to be a viable method for using a moderately powered, fiber-delivered Nd:YAG laser to cut thick mild steel plates. This technique is effective for cutting mild steel up to 32 mm thick with low-pressure gas delivery. For greater thicknesses, high-pressure gas delivery allows for cutting up to 50 mm thick steel, while also enabling rapid piercing of the material. However, challenges persist in achieving consistent cut quality, especially in terms of shock artifacts and undercutting at corners, which can be addressed through precise CNC programming. Moreover, successful piercing of thicker plates requires managing the removal of ejected dross to ensure that the assist gas flow is not obstructed, thereby maintaining high cut quality during the rest of the cutting process.